As technology advances, Radio-Frequency Identification (RFID) sensors have become increasingly important in the logistics industry. This is because they are now irreplaceable for a variety of businesses such as transportation and storage. The usage of RFID sensors has increased over the years to help companies improve efficiency, accuracy, productivity and safety. This article discusses how technology uses RFID sensors to provide for a smoother process, as well as showcase examples of companies that adopt the RFID technology. By examining the application of RFID sensors across these six technologies, this article aims to demonstrate how RFID sensors have revolutionized the entire logistics industry.

Table of Contents

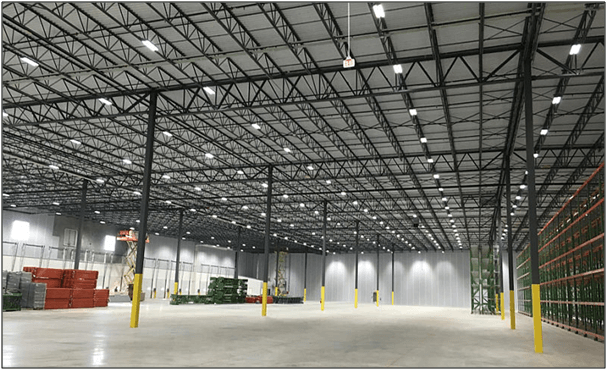

Light Sensor Technology

RFID lighting tags are equipped with Light-emitting diode (LED) lights as part of a new breakthrough in RFID technology. When attach the tags on the product items, it will have a much easier time being identified by RFID sensors and other RFID devices. There is one added advantage: the objects which emit these special lights can also help quickly identify which of tagged items need to be replaced. Pick the Electronic Product Code (EPC) number for the tag that needs to be located in the area want to search from, and then press either “ON” or “OFF” on the RFID electronic tag’s screen. The LED lights will flash so know it has been turned on. Quickly find and replace any tagged object that is out of stock. As such, it helps to increase the effectiveness and accuracy of locating items.

Logistics Asset Tracking

Logistics asset tracking system using RFID electromagnetic fields to transmit data from an RFID tag to a reader. With a portable RFID reader built into a mobile computer, staff can scan one or more asset tags without seeing them. Automated tracking with RFID provides a complete view of asset fleet. With RFID asset tracking system, it helps organisations increase asset visibility, eliminates delays in product deliveries and more importantly mitigates loss, theft and risk. Zara is one such retailer using RFID asset management technology for inventory tracking; and to tackle the counterfeit problem in the clothing industry. It helps in restocking racks of fast-selling clothes and gives exact information about all clothes in terms of sizes, models that need replenishing and availability across stores. Such automated tracking with RFID provides a complete view of their assets at all times which is in contrast to traditional barcode – based systems which require line of sight.

Autonomous Vehicle Platooning

RFID technology powers vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication. This tech provides driverless cars with a wealth of info to help them navigate, recognise traffic signs, estimate distance from other cars, park, and more. RFID also helps vehicles detect their location and distance from other cars up to several kilometers away. These result help less braking and accelerating for lower fuel consumption. One of the biggest benefits of RFID is that it does not require a line-of-sight like other technologies, such as Global Positioning System (GPS) or lidar. This means that driverless cars equipped with RFID can “see” through bad weather and even darkness. RFID is also much cheaper than other similar technologies. This makes it a more attractive option for carmakers who are already struggling to keep the cost of driverless cars down. In the future, RFID will become an increasingly important part of the driverless car ecosystem as more and more vehicles are equipped with this life-saving technology.

Freight Tracking System

Freight tracking gives real-time, 24/7 visibility of shipment’s progress. With freight tracking platforms, can stay updated on the exact location and estimated time of arrival. RFID and other Information and Communication Technology (ICT) innovations are widely used to identify vehicle locations and containers that use e-seals. RFID infrastructure requires RFID readers and antennas to identify containers at all gates and spreaders. With RFID technologies, ports and customers can get real-time location and status information, automated alerts, and analytics for better tracking and tracing of containers at both the terminal and supply chain levels. One such application is the use of RFID e-seals on containers. These e-seals are able to track the location of a container and can also be used to create a geofence around the container. This means that if the container leaves the specified area, an alarm will be triggered. This type of system can be used to track the movement of freight containers around a port or other restricted area.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.