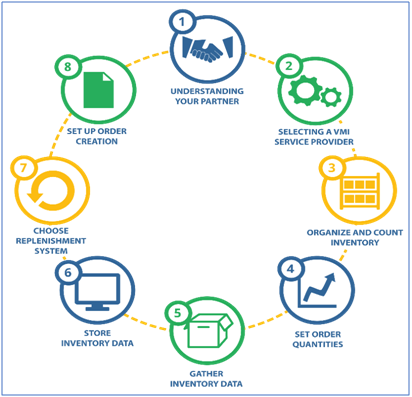

Supplier-Managed Inventory (SMI) is the process whereby a supplier plans, manages and replenish inventory for a customer. Extensive information sharing is required so that supplier can maintain a high degree of visibility of its goods at the customer’s location. Instead of the customer reordering when its supply has been exhausted, the supplier is responsible for replenishing and stocking for a customer at appropriate levels.

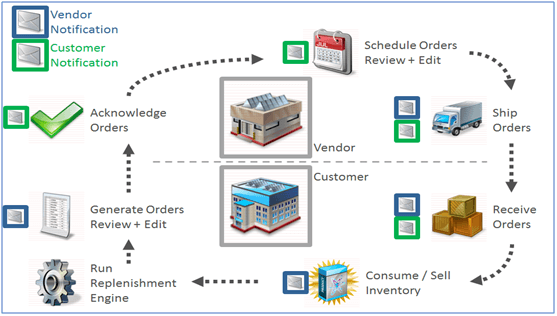

The goal of SMI relationship is to make sure the customer only buys what they will sell. Customer maintains closer contact with the supplier, aided by technology, so they can purchase stock in smaller batches but more frequently.SMI typically facilitated with communication technology such as EDI (Electronic data interchange), APIs (Application programming interfaces) and XML (Extensible Markup Language), which allows both supplier and customer to communicate directly and exchange information.

A successful SMI solution can be a win-win situation for both supplier and customer. The collaboration helps everyone involved benefits.

Table of Contents

Reducing Inventory Investment

SMI can help to reduce costs associated with inventory management due to emergency or rush orders, understocked and overstocked inventories. In business, cash flow is closely tied-up with inventory levels, when cash is used to purchase inventory (that may never sell), that cash can’t be used to operate the business or invest in other growth opportunities. Every business wants to minimize their stock level to hold a little inventory as possible without running out, and it is usually a tough balancing act.

Supplier will take the burden in the case of SMI, supplier will monitor and replenish which goods customer needs and when, and they will get them for customer just in time. Pre-agreement must be worked out by both parties for a detailed arrangement with clearly defined terms such as inventory hold periods, must-take deadlines, payment terms etc.

With a successful SMI relationship, customer is rarely run out of stock as customer is less likely to under purchase in order to avoid excess stock. Meanwhile, they no need to worry of missing sales due to stock-outs by making extra purchase. Supplier has frequent visibility into the customer’s stock, it can push smaller deliveries, more frequently, based on customer’s needs and how quickly the items are selling, before it runs out of stock. As such, customer is able to reduce financial liabilities of inventory and improve the closely managed inventory turnover ratio (sales ÷ average inventory) as they do not need to hold so much inventory to ensure the order fulfilments or sales.

SMI distributes the inventory risk, so it’s shared between the supplier and customer. This tight relationship significantly reduces the risk of stock-outs and get customer as close as possible to buy exactly the amount of inventory that will sell.

Reducing Operating and Administrative Costs

Working with a supplier who can handle purchase orders and inventory replenishment not only save time and labour, it results in cost-savings from many aspects.

SMI reduces the total cost of ownership (TCO), as customer won’t be spending time or money on POs or inventory management. Customer can benefit from reduced purchasing cost because the supplier receives data and not purchase orders, the purchasing department has to spend less time on calculating and producing purchase orders. In addition, the need for purchase order corrections and reconciliation is removed which further reduces purchasing costs.

Typically, a supplier’s customers are distributors or retailers. They are often receiving from hundreds of different suppliers and many different locations. For this reason, it is hard to keep track of inventory moving in and out. This is where SMI comes in to defer responsibility. It lowers costs, reduces admin work, and allows them to focus their efforts on other areas within their business.

Since SMI is much more streamlined than traditional inventory systems and makes use of automated inventory counts, employees need not to conduct physical stock count manually. Automated inventory counts are more accurate and it helps conserve valuable staff time and company resources. With a SMI in place, supplier can deliver goods in smaller quantities on a more frequent basis, so employees won’t need to spend as much time organizing and putting away large inventory shipments. Cost saving can also be found in reduced warehouse costs. Lower inventories can reduce the need for warehouse space and warehouse resources.

Meanwhile, SMI use technology and system to store data, hold electronic records and receipts. As such SMI is able to manage orders and deliveries electronically while facilitating the communication between the supplier and customer. It also helps both parties create a “greener” footprint by reducing unnecessary paper waste.

Closer Partnership

Cooperative business is a win for everyone involved. SMI relationships are one manifestation of improved partnership. SMI requires a high degree of trust between supplier and customer, it develops a real partnership that brings about lower cost and higher efficiencies.

The SMI strategy requires both supplier and customer to link their business processes and technology platforms more closely. When businesses are linked together, it creates a closer business partnership for a shared goal. This partnership can produce more innovative solutions for customer at lower costs. Supplier is able to manage customer’s requirement and mitigate unanticipated fluctuations in seasonal demand and market shifts, this mean that supplier will have the product when customer needs it most.

In today’s highly competitive marketplace, both supplier and customer are needed to find innovative ways to differential their offerings, ensuring a steady flow of products and high shelf availability are the keys to success. SMI is a demand-driven continuous replenishment process focused on getting “The right product to the right place at the right time”, it improves sales by managing delicate balance between shelf presence and inventory turns.

Communication is important for a successful SMI, both supplier and customer are required to engage in regular performance reviews and scorecard sessions to evaluate results and make changes when necessary. It brings a natural framework for collaborative and data-driven performance management. Besides improving general shelf availability, supplier and customer can work together to grow sales, trading partners doing SMI get better results from promotions, they do a better job of new product introduction and they evolve to a better overall product mix.

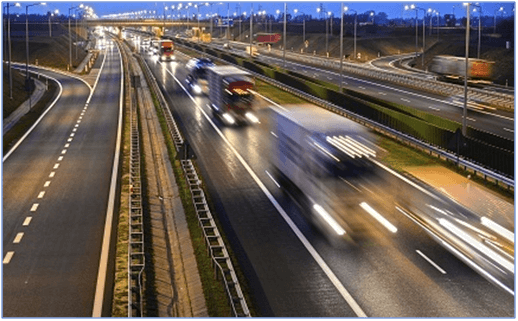

Reducing Transportation Cost

Transportation costs may erode supply chain cost savings. A successful SMI program help to reduce transportation cost from better utilization of transportation capacity.

A well-functioning SMI process gives supplier the demand visibility needed to build fuller trucks while always shipping the customer’s most needed items. With SMI, suppliers are in a far better position to achieve high average Vehicle Fill Rate (VFR) to improve their bottom line while at the same time delivering high inventory turns to improve your customer’s bottom line. A higher VFR means fewer trucks being sent out, that means lower transportation costs and improved sustainability. It also enables suppliers to drive other efficiencies such as case picking and ordering in full pallets and layers.

Conclusion

Cost is the top business challenge today. Cost reduction and efficiencies are the top business priorities in procurement across all industry sectors. Inventory is the backbone of the business, not having goods at the right place and time will put a business at risk. A successful SMI reduces lead times to saving money and improving productivity while lowering your overall inventory investment.

References

Ben Ng Boon Hee, DPSM. (2018). “Key Strategies to Enhance Supplier Relationship”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-strategies-enhance-supplier-relationship, accessed 10/12/2018.

David Wong, DPSM. (2018). “Supplier-Managed Inventory for Central Kitchen Operation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/supplier-managed-inventory-central-kitchen-operation, accessed 10/12/2018.

Doug Bethea. (2014). “How VMI Helps Reduce Outbound Transportation Costs for CPG Companies”. Retrieved from https://publication.sipmm.edu.sg/key-strategies-enhance-supplier-relationship, accessed 10/12/2018.

Jeswin Philip. (2018). “Vendor-managed inventory and distribution planning in the food and beverage industry – here’s something to chew on”. Retrieved from https://blog.kinaxis.com/2018/02/vendor-managed-inventory-distribution-planning-food-beverage-industry-heres-something-chew, accessed 10/12/2018.

MausmiAmbastha. (2017). “Vendor Managed Inventory (VMI)”. Retrieved from https://stitchdiary.com/vendor-managed-inventory-SMI, accessed 10/12/2018.

Patty Rasmussen. (2017). “Benefits of Using a Vendor-Managed Inventory Program”. Retrieved from https://news.ewmfg.com/blog/benefits-of-using-a-vendor-managed-inventory-program, accessed 10/12/2018.

Ryan Lunka. (2015). “Vendor-Managed Inventory Benefits & Advantages”. Retrieved from https://www.nchannel.com/blog/vendor-managed-inventory-benefits-advantages, accessed 10/12/2018.