Outsourcing is the complete transfer of a business process to an independent external organisation. The reasons for outsourcing could be due to uncertain market situation at where the company is located, company’s efforts to restructure the process flow of departments, so as to achieve economies of scale as well as efforts to reduce costs from skilled labour to raw materials. Outsourcing can be deemed effective and thus successful when it helps companies to achieve better quality, quantity, delivery, cost, service, lower risk and greater opportunity for the company’s competitive position and greater customer satisfaction.

Table of Contents

Categorisation as a Procurement Strategy

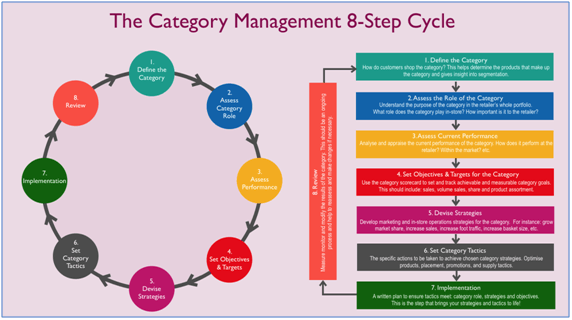

Categorisation is a form of category management used in procurement/purchasing. It is a strategy where the Procurement Managers in organisation cluster and centralise similar goods and services. By doing so, it eases administrative procedures and lower prices of goods and services through bulk purchases. Therefore, by applying categorisation strategy, it would be easier for organisation to outsource part of their procurement processes successfully. It would also effectively assist organisations in checking for the performance of their hired outsourced department.

As categorisation is a strategic approach, as a guide, there is an 8 stage cycle on how category management can be conducted in organisations.

Supplier Integrative Negotiation

Negotiation is the process whereby both parties (organisations and suppliers) attempt to reach an agreement. It is a technique to get the goods or services at a lower price, with changes in terms and conditions that one deemed fit; instead of accepting what have originally been offered by the suppliers. It is an art of haggling about anything in the goods or services.

Integrative negotiation, also known as win-win bargaining, is a negotiation strategy whereby two or more parties (organisations and suppliers) collaborate to find a “win-win” solution during an agreement. It is important for successful outsourcing because it produces satisfactory outcomes which fulfil the interests of both the organisations and suppliers.

Integrative negotiation is crucial as it produces more satisfactory outcomes for both parties involved than what positional bargaining offers. Positioning bargaining is based on fixed, opposing viewpoints; and tend to result in compromise from one of the parties.

The table below shows the factors to consider during positioning bargaining and integrative bargaining (negotiation). It also reflects the differences between the two types of bargaining; to prove why an integrative approach to negotiation is the preferred strategy to ensure successful outsourcing.

| Positional Bargaining | Integrative Bargaining (Negotiation) |

|---|---|

| Disputants are adversaries Goal is victory Demand concessions Dig into position Mislead, use tricks Insist on your position Apply pressure Look for win for you alone |

Disputants are joint problem-solvers Goal is wise decision Work together to determine who gets what Focus on interests, not positions Be open about interests, use fair principles Insist on objective criteria; consider multiple answers Use reason; yield to principle, not pressure Look for win-win opportunities |

Table adapted from https://www.beyondintractability.org/essay/interest-based_bargaining

Integrative negotiation is an effective strategy to ensure successful outsourcing. This is because both the organisations and suppliers have to agree on who gets what; such that ultimately, the best value of interests are met by both parties.

The main basis of this strategy is to create a cooperative working relationship between organisations and suppliers; thereby ensuring a positive Supplier Relationship Management (SRM).

Measuring Suppliers Performance

To ensure successful outsourcing, a set of supplier performance measurement is necessary. It helps to determine whether during the outsourcing process, the suppliers are performing up to expectations. This can be measured in terms of these 3 tools – KPI Measurement, Performance Monitoring and Performance Analysis.

1. Key Performance Indicator (KPI) Measurement

Key Performance Indicator (KPI) is a tool used to measure the success of the organisation; or the progress of crucial activity the organisation undertakes. It varies in different organisations and/or suppliers.

For a call centre department, the KPIs should focus on managing the outsourced goods or services; for successful outsourcing activities, such as:

- Customer satisfaction

- Inbound call centre service levels

- First call resolution rate (FCR)

- Conversion metrics

- Call quality

- Average handling time

2. Performance Monitoring

Performance monitoring is used to measure suppliers’ performance. It is measured by the rate of responses of procedures and resources which the suppliers can react to the organisations. Such performance measurement are performed and recorded on a regular basis, to ensure consistency and thus ensures successful outsourcing. The diagram below shows how a logical management structure (during performance monitoring) can be categorised under eight dimensions.

The Supply Chain Manager in the organisation should be well-organized and have logical planning capabilities for performance monitoring to occur. When the manager analyse and check for improvements, he will therefore be able to measure the outcomes of performance when conducting the outsourcing strategy. To ensure an effective outsourcing strategy, this performance monitoring should be performed every quarterly and recorded on a regular basis.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Academy, A. O. (2017). “What Are Supplier Performance Measures?”. Retrieved from ADR International: http://www.adr-international.com/insights/what-are-supplier-performance-measures, accessed 21/12/2018.

Council, N. R. (2000). “Surviving Supply Chain Integration: Strategies for Small Manufacturers”. Retrieved from The National Academies of Sciences Engineering Medicine, NAP: https://www.nap.edu/read/6369/chapter/8#56, accessed 20/12/2018.

Hao, D. (2018). “How Category Management Can Decrease Your PO Processing Time”. Retrieved from Procurify: https://blog.procurify.com/2018/07/16/what-is-category-management-and-how-does-it-tie-into-procurement, accessed 21/12/2018.

Insider, O. (2015). “4 Key Factors For Outsourcing Success”. Retrieved from INFINIT-O Endless Opportunities: http://www.blog.infinit-o.com/4-key-factors-outsourcing-success, accessed 17/12/2018.

Kotlarz, C. (2016). “6 KPI’s to Effectively Manage Your Outsource Call Center”. Retrieved from LinkedIn: https://www.linkedin.com/pulse/6-kpis-effectively-manage-your-outsource-call-center-corey-kotlarz, accessed 22/12/2018.

Lau Chee Leng, DPSM. (2018). “Eight Essential Steps for an Effective Global Sourcing Strategy”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/eight-essential-steps-effective-global-sourcing-strategy, accessed 17/12/2018.

See Yin Qian, DPSM. (2018). “Key Stages to Develop a Global Sourcing Strategy”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-stages-develop-global-sourcing-strategy, accessed 17/12/2018.

Spangler, B. (2003). “Integrative or Interest-Based Bargaining”. Retrieved from Beyond Intractability: https://www.beyondintractability.org/essay/interest-based_bargaining, accessed 22/12/2018.

Webb, J. (2015). “What Is Category Management”. Retrieved from Forbes: https://www.forbes.com/sites/jwebb/2015/12/23/what-is-category-management/#6df659385dbf, accessed 21/12/2018.