Where do you get your food from, and where does the Food waste go? I am sure most of us will have the same answer as me: from the Grocery Store to the Dustbin. The point is, we expect food to be readily available. We expect our society to produce food through ethical agricultural practices, and we expect there to always be enough to sustain our growing population. The fact is, we have no clue on the food losses during harvesting, collection, thrashing, grading, sorting, winnowing, cleaning, drying, packaging, transportation, storage and its detrimental impact on the economy, environment, climate change and ultimately on Biodiversity.

The growing concern about food waste in landfills; makes a compelling reason for Agro-food industries, Distributors, Retailers and Consumers to begin developing plans for Reverse Logistics, which may seem implausible since re-processing of food for human consumption isn’t usually an option.

Table of Contents

Extent and Impact of Food Waste

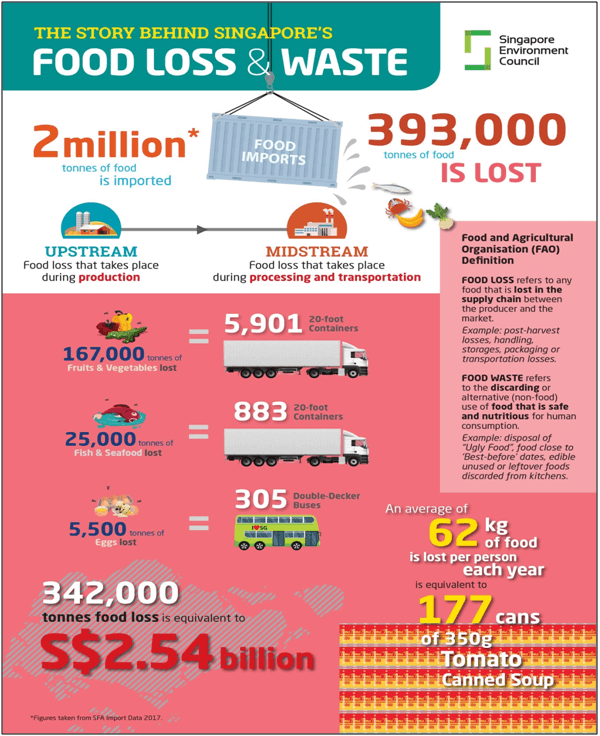

One-third of the food produced globally is not really consumed. Carbon footprint of food supply is at 3.3 billion tons of greenhouse gases; making food wastage the third top Green House Gas emitter after the U.S. and China. Also, the blue water footprint of food wastage is three times the volume of Lake Geneva.

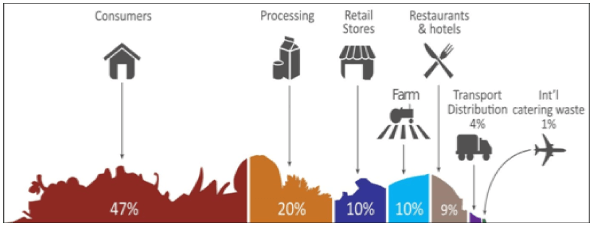

Fifty-four percent of the world’s food wastage occurs “upstream” during production, post-harvest handling and storage and 46 percent of it happens “downstream” at the processing, distribution and consumption stages. Even in a small country like Singapore who completely relies on food imports, 20% of food loss is unavoidable.

Reverse Logistics in Agro-Processing Industry

Reverse Logistics can be applied on the Agro-Food Processing Industries to reduce food wastage and to provide quality and safe food to consumers without posing any serious threat on human health, well being and the environment.Retro Logistics is the only sustainable solution in food supply chain for excessive buying, premature harvesting, inadequate labeling and storage instructions, poor storage facilities and transportation, production errors, trial runs, packaging defects, and wrong weights and sizes which directly affect stock forecasting, continuous food supply, quality management, return and waste management.

Challenges in Reverse Logistics of Agro-food Products

Biggest challenge of reverse logistics processes for Agro-food products is its perishable nature that can be rendered unsafe by even small lapses in process controls hence creating a food safety incident and subsequently can pose a possible threat to consumer’s health.

Companies in the Agro-food processing industry strive to avoid returns and rejected loads whenever possible. If returns still occur, the process usually consists of checking the batch number, writing the load off, and making the trip to the nearest food bank or dump in landfill, which is the second challenge of reverse logistics in the food industry: absence of established practices, networks and manpower in order to safely enable the return of products.

Every return that occurs in the food supply chain is treated as a unique individual transaction, and therefore, these returns tend to have higher operational downtime and expenses. They can also disrupt the existing forward supply chain since they may repurpose facilities and personnel to handle a transaction they don’t usually perform.

Key Performance indicators for Agri-Reverse Logistics operations

• Speed. critical for short shelf life product demanding swift reverse logistics operations.

• Flexibility. critical during food processing stage where companies can differentiate and decide whether to re-sell to less premium/secondary market, re-process or discard.

• Quality/Reliability. the sooner a company identifies quality problems, the faster they can be dealt with. (e.g. Maple Leaf Foods – listeria contamination in Toronto facility forcing distributors and retailers to recall)

• Sustainability. reverse logistics to be included in sustainable strategy, emphasizing on Recycling and Reuse initiatives to reduce waste disposal.

Key Factors for Reverse Logistics operations of Agri produce

In the food industry, distraction and disruptions are especially problematic because of the potential for food spoilage due to lapses in physical and environmental controls. Reverse logistics in the food industry demands carefully developed practices tailored to a reverse supply chain as well as transportation assets and facilities.

Some of the key factors in setting up the Reverse Logistics operations are:

• In-Store vs Consolidation: Choosing in-store v/s consolidated returns operations is challenging. Former can help in quick disposition and potentially resell returns immediately; hence returning qualified stock back to shelves and liquidating low retail price inventory on-site, whereas later can be automated once all returns are aggregated hence reducing manpower in low value adding task such as recycling.

• Sorting and Segregation: This process needs to be optimized in order to avoid excessive spending on transportation i.e. moving product back through the supply chain only to dispose it without making any additional value. Also, large volume of similar type of products are likely to be handled more efficient than a group of products with divergent characteristics.

• Transportation Management: Reverse supply chain has its own practices and needs, hence using transportation and facilities that serve existing forward supply chain can cause disruptions and interfere in getting sell-able products to the market. However, this can be avoided by simplifying the operation i.e. by allowing each store to return material only when they are the last in the supply route since for retailers with multiple supply stores it is most efficient to collect the returned material to the Distribution Centres with the same truck that delivers the products. So, by including number of stores in the return route have economies of scale.

• Warehousing Management: Designing warehouse to accommodate dedicated facility for return handling, storage, waste management and integrating with forward sale or re-processing as warehouse deals with returns of products, carrier material (roll cages, crates, pallets), and waste (paper, plastic, disposable products etc). From food retailers all returned products nearing to end of the life cycle are not always saleable at original price; but can be put again in the inventory to be re-sold in different market.

• Information Management: Efficient information systems are needed for individually tracking and tracing product returns and linking them to initial sale. Smart Retailers uses barcodes, computerized return tracking, electronic document interchange and radio frequency to enhance their reverse logistics operations and traceability. RFID technology can also be used to effectively protect against the return of counterfeit items – a critical issue in agricultural industries where manufacturers must safeguard and monitor batches and lots, as well as expiration dates on products.

Recommendation for Reverse Logistics operations

• Better In-house Operations: Food retailers and processors can speed up the process and reduce waste through better screening, segregation, centralized return authorization and outsourcing transportation with own pick up schedule.

• Efficient Warehouse Layout: For efficient handling, the design of the warehouse’s layout must bear in mind the return handling (receipt location and future storage locations) and not only the forward flow.

• Automation: To automate the return handling for homogeneous returns like carrier material (roll cages, crates, pallets) may simplify operations.

Conclusion

Landfill disposal might be a simplest option, but it should be a last resort for both financial and environmental reasons. Ideally, recalled food product should be composted and any packaging recycled. Organic waste should be converted to renewable energy through anaerobic digestion while polymeric materials should be recycled and reused. Hence, Reverse logistics in the Agri industry demands carefully developed practices tailored to a reverse supply chain as well as transportation assets and warehousing, storage facilities – all with accurate information flow to provide traceability and closing the loop.

References

Anthony Wong, ADPSM. (2019). “New Emerging Technologies Food Supply Chain”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/new-emerging-technologies-food-supply-chain, accessed on 17/09/2019.

Cyrus Leong King Fatt, DLSM. (2019). “Integrated Logistics Practices for the Food Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/integrated-logistics-practices-food-industry, accessed on 17/09/2019.

De Koster, R. and De Brito, M. et al. (2002). ”How to organise return handling: an explanatory study with nine retailer warehouses”, Econometric Institute Report EI 2001-11:05-10, accessed on 17/09/2019.

Food and Agriculture Organization of the United Nations. (2011). “Global Food Losses and Food Waste”. Retrieved from http://www.fao.org/save-food/resources/publications/en, accessed on 17/09/2019.

Mwaura, Anne. Letting, Nicholas.et.al. (2015). “Reverse Logistics Practices and Their Effect on Competitiveness of Food Manufacturing Firms in Kenya”, International Journal of Economics, Finance and Management Sciences, 3(6): 678-680, accessed on 17/09/2019.

Sathiyagothai, B. and Saravanan, S. (2017). “Reverse Logistics in Food Processing Industries in India”, International Journal of Economics and Management Sciences, 6 (408):02-03, accessed on 17/09/2019.