Oil storage terminals are facilities for storing crude oils and petrochemicals products worth billions of dollars. Terminals operators are facing stiff competitions within the industry, they are pressurised to optimise their storage tanks to operate efficiency and maximise storage capacity. Furthermore, they are required to hit the performance and safety levels required by customers, as well as regulatory agencies.

Table of Contents

Importance of Effective Procurement

Procurement holds an important role in oil storage terminal, Effective Procurement helps in keeping operational costs down and can be strategic for a business to be able to optimally utilize its resources. It also helps with quality control and product categorisation, ensuring on-time delivery on site and cost saving (without jeo pardising quality and safety).

Within the oil storage terminal business, procurement costs can be huge owing to the size of the business itself. Even slight changes can show a significant difference in the operating costs. Thus, to improve the efficiency of procurement in the oil storage terminal, incorporating automation and digital technologies is crucial. I shall discuss RFID technology in warehousing control and control of maintenance and inspection.

Radio-frequency identification Device (RFID)

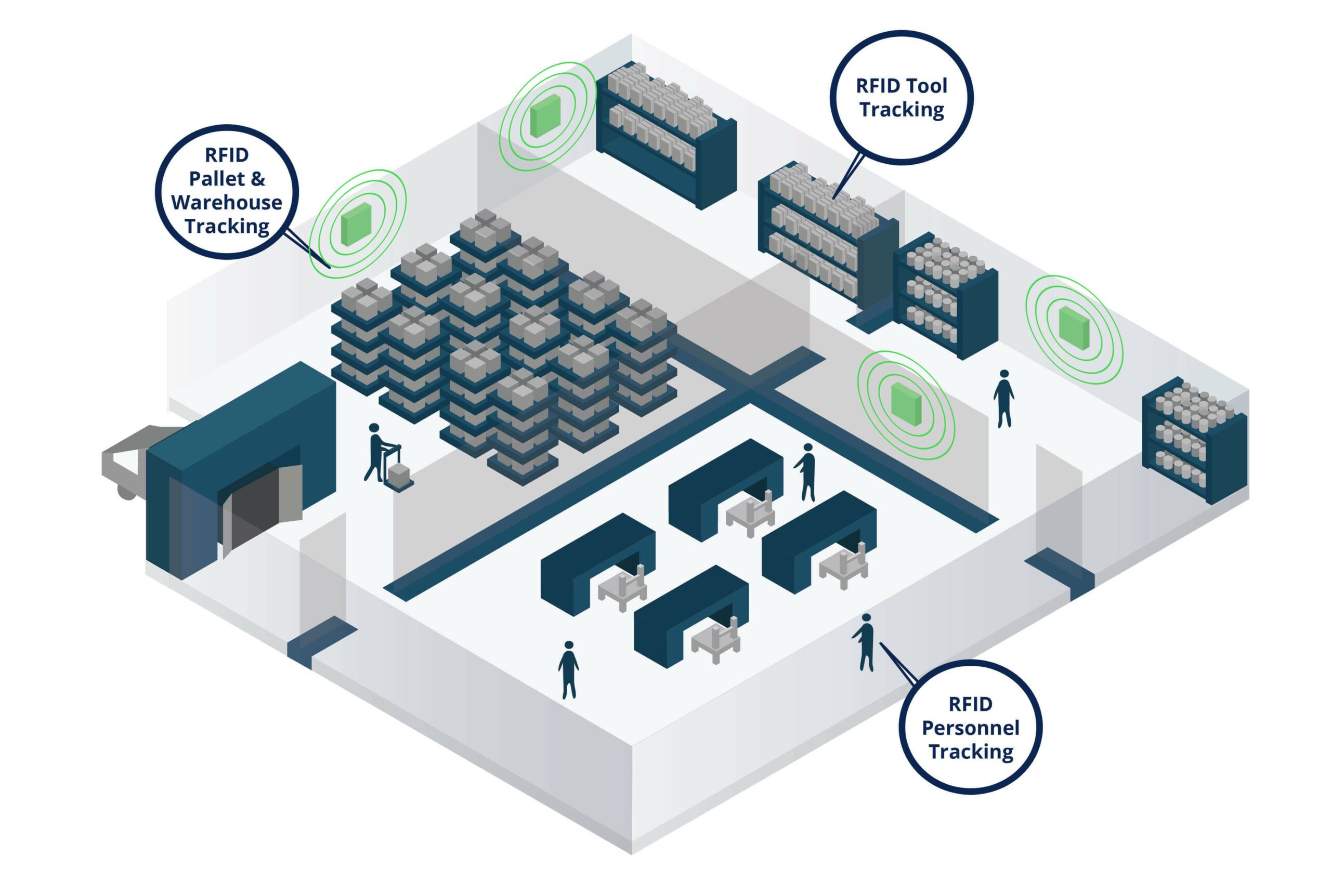

RFID is a radio waved-based technology, its tags is different from barcodes, because tracking chips do not need to be in-line with barcode scanner to return data. RFID tags can also be “active” or “passive”. Active technology has a local power source (like an in-built battery) making it capable of operating hundreds of meters away from a reader.

Passive RFID relies on the radio emissions of a reader device to activate a geolocation reading and other essential documentation. Based on a unique serial number connected to the tag, full history of the items can be accessed. The advantages of RIFD technology is that it can tailor to associate different datasets with given assets and can recall operational information.

RFID on Assets Control

• RIFD technology can identify, track, manage and optimize the deployment of critical assets for improved business efficiency. By enabling improvements in sourcing, visibility, security and accuracy, it also helps to ensure the right asset is in the right place at the right time, and allows accuracy and visibility to assets control.

• RFID tags can provide real-time notifications when tagged items leave secure areas, thereby reducing the likelihood of inventory shrinkage due to theft.

RFID on Warehousing

Maintaining high stock of equipment and materials incurred risks and costs for oil storage terminal. It requires large warehouse space, equipment and people to manage the operations. Unlike other industries, oil storage terminals is not driven by moving high number of SKUs; safety and reliability is the point. To achieve the most effective practices in the flow of materials, stock turn rates, space utilization, inventory and information flow between the warehouse and procurement department, RFID technology might be the answer.

Benefits of RFID for Oil Storage Terminal

• Fast to implement – RFID technology require less monitoring than predecessor, the barcode. You can just simply install the tags on inventory and you can start to gather data.

• RFID technology reduce human errors – automatic data logging and collation within RFID tags and reader devices eliminates the need for staff input, which reduces the risk of human errors skewing data results and lower rate of shelving errors too. It speeds up the receiving process.

• RFID technology enables tracking real-time product information – Allows management to have full information to analyse and do strategies planning. This information also allows procurement department to practice effective purchasing (6R), order the equipment and materials at

(1) Right Quantity

(2) Right Quality

(3) Right Price

(4) Right Time (Just-in-time)

(5) Right Place

(6) Right Source.

• Inventory control – RFID can more easily deliver correct and current information about current inventory levels and can eliminate the need for manual reconciliation.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

BernadineM (2019). “Tanks and Terminals 2019: Operations, Maintenance and Integrity”. Retrieved from https://www.digitalrefining.com/637,events,Tanks_and_Terminals_2019__Operations__Maintenance_and_Integrity.html#.XX48US2p3s0, accessed 21/09/2019.

DALEEL. (2019). “Storage and Warehousing”. Retrieved from https://www.scmdaleel.com/category/storage-amp-warehousing/189, accessed 21/09/2019.

Jason Goh Yeow Loong, PDPM. (2018). “Five Effective Methods for Selecting Suppliers in the Oil and Gas Industry”.

Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-effective-methods-selecting-suppliers-oil-gas-industry/, accessed 21/09/2019.

Mork Choo, DPMM. (2017). “Effective Procurement Practices in the Marine Offshore & Shipbuilding Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/effective-procurement-practices-in-the-marine-offshore-shipbuilding-industry/, accessed 21/09/2019.

Naresh Kumar, DLSM (2019). “Digital Technology warehouse productivity”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-warehouse-productivity, accessed 21/09/2019.

NurZawiah Omar (Zee), DPSM (2019). “Key Procurement Strategy for the Oil & Gas Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-procurement-strategy-oil-gas-industry, accessed 21/09/2019.