Procurement refers to the process of sourcing or obtaining goods and services. It involves the strategic implementation of Purchasing, as well as active interaction with both the internal customer and external suppliers. Each company has their own processes and policies with regards to the implementation of these practices.

However, no single procurement policy is effective without streamlining the process and taking into consideration various ways where the company can save time, money, and other resources. A good system or strategy is necessary for this process to be efficient and reliable while taking away opportunities for resource wastage. All companies emphasize the utilization of sustainable product and to lessen wasted resources. Subsequently, purchasers have expanded their resources to attain sustainable procurement strategies.

Table of Contents

Lean Procurement Strategy

One strategy is the Lean Procurement practices where companies utilize innovative web technology and web solutions to streamline the procurement process, reduce spending and provide measurable accountability.

It uses a Lean team approach to optimize the end-to-end procurement process. It also helps to eliminate wasted activities and making ordering efficient. Adaptation of Lean Practices in Procurement is considered as the solution in improving procurement effective process and essential work. These improvements in the procurement processes and workflows will benefit multiple departments in the organization allowing them to focus on the activities that add value to the company.

Eliminating Waste in Procurement

Optimizing process to eliminate waste is crucial for the successes for the organization. These wasteful activities can lower profitability, increase customer costs, decrease quality, and even affecting employee satisfaction.

Identification of the non-value adding activities and try to improve the process where they appear or ultimately eliminate them.

- Overproduction due to collaborating with supplier at inadequate levels of granularity leading to redundancy

- Wait Time due to administration time for creation of supplier accounts in duplicate ERPs

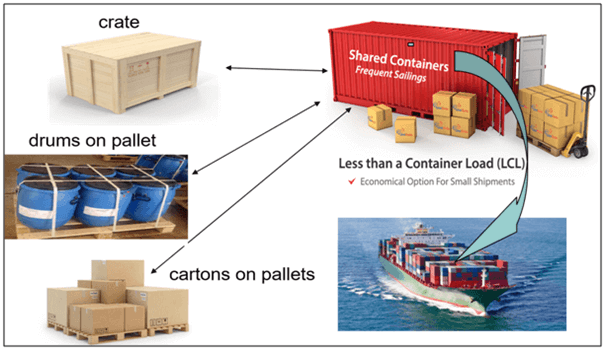

- Inefficient transport due to sub-optimal freight loads coming from suppliers.

- Useless stock due to over-commitment on volumes of obsolete goods

- Over-quality due to those contracts covering goods or services never used or redeemed

- Inefficient process due to incorrect information systems (IS) and remoteness of internal clients

- Redundancy or reworking erroneous IS, such as nomenclature, suppliers etc.

Lean Practices in Procurement

As the main goal of the company is to remove the waste and maximize profit, below are some common lean practices adopted by the organization.

- Strategic Sourcing

- Centralizing Procurement

- Supplier Consolidation

- Managing Supplier Relationship

- Just-In-Time Procurement

- Streamliningthe Procurement Process

Strategic Sourcing

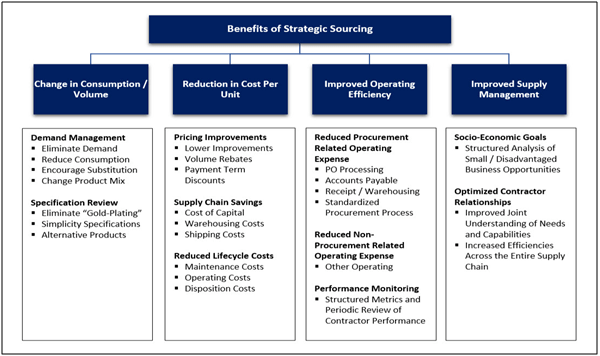

Strategic Sourcing refers to the long-range plan to ensure a timely supply of good services, especially in the Food Industry. It incorporates action aimed to reduce overall supplier based, negotiations, communications and working to maintain long-term relationship with the supplier. It is important in terms of globalization, on the sales side. It deals with the development of cost-saving communications and IT, improved procedures and logistics, high consumer demands, increase in environmental awareness and transparency of requirements.

Centralizing Procurement

Centralizing procurement is a strategy whereby all of the departments of the organization with a wide geographical distribution can request the purchases through one common purchasing organization. It is a purchase of all required goods and services by a single department for all the branches of the entire company. Centralized procurement is useful in having the best deals with local sources for the corresponding location of the company department, avoids duplication of orders and promotes advantages arising from high volume bulk discounts, lower transportation costs and inventory management costs.

Supplier Consolidation

Supplier Consolidation is a supply chain management strategy in which purchasing companies reduce the number of suppliers they work to a few partners. Using this strategy, business focus their resources on a single partner or a small group of reliable suppliersas opposed to a wide array of companies. The ultimate aim is to maximize portability while reducing time spent on managing supplier relationship.

Supplier consolidation ultimately reduces supply management requirement. To make the most of this strategy, companies should narrow down their suppliers, not just based on price but also other criteria, such as location (freight costs) and quality of service.Benefits are increase purchasing power, reduce shipping cost, time savings, stronger partnership and improved vendor acquisition processes.

Managing Supplier Relationship

Suppliers play an important part in procurement. Having a significant plan about how to manage these relationships can bring a major impact on cost savings. For example, restructuring supplier relationships is a key factor to be considered. More value can be obtained in terms of the relationships with suppliers through intense collaboration or by starting up partnerships with them. Exploring alternative sources is also a good way to save costs, especially if your current supplier is considered ‘high-priced’ within the industry. Advanced negotiation skill is required to deal with suppliers to minimize costs and tactfully maintain good relationship with them. A cost profile can be created for all the key suppliers to further save cost. This will consist of what’s being purchased and from which source. All of these will give a clear view about expenses and whether the suppliers are really meeting the needs of the company.

Just-In-Time (JIT) Procurement

JIT is management method that aligns raw-material based orders or requirements from vendors directly with production schedules. This strategy utilizes to eliminate and wastes by getting the goods only as they need for production process, which reduces inventory costs. This requires producers to forecast demand accurately. For JIT to be successful and effective, company must have good planning and steady production, glitch-free plant machinery and reliable suppliers. JIT production system reduces inventory costs because manufacturers do not have to pay extra for storage costs. Manufacturers are also not left with unwanted inventory if an order is cancelled or not fulfilled.Kanban system highlights problem areas by measuring lead and cycle times within production process which helps identify upper limits for work-in-process inventory, in order to avoid overcapacity.

Streamlining the Procurement Process

improvement in the procurement process and workflow significantly reduce time to process orders. Procurement cycle time elapsed from placing or creating requisition to receiving of goods. Decreasing the cycle times associated with procuring materials services is an effective way to cut procurement costs. Digital procurement is an exponential move that allows organizations to better deliver on their mission with fundamentally different process at a reduce cost. Digital technologies and tools can optimize organization’s procurement mission and management.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

IBM Institute for Value Business. (2019). “Cognitive Procurement: Seizing the AI Opportunity”. Retrieved from https://www.ibm.com/downloads/cas/MV6LX6R2, accessed on 17/09/2020.

Jagger Staff (2018). “Cognitive Procurement – It is the Final Frontier?” Retrieved from https://www.jaggaer.com/cognitive-procurement-is-it-the-final-frontier/ accessed on 16/09/2020.

Josh Hanstedt (2019). “5 Best Practices for Implementing Lean Manufacturing”. Retrieved from https://www.mcl.bz/blog/5-best-practices-for-implementing-lean-manufacturing, accessed on 10/09/2020.

Li Gui Li, ADPSM. (2020). “Five Digital Technologies for Procurement Optimization”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-digital-technologies-procurement-optimization/ accessed on 17/09/2020.

Purchase Control. (2020). “Strategic Procurement: What It is and How To Implement It”. Retrieved from https://www.purchasecontrol.com/blog/strategic-procurement/ accessed on 20/09/2020.

Ruth Ng Yin Fun, ADPSM. (2019). Digital Analytics and Artificial Intelligence for Cognitive Procurement”. Retrieved from: https://publication.sipmm.edu.sg/data-analytics-artificial-intelligence-cognitive-procurement/ accessed on 17/09/2020.