In industry 4.0, procurement activity will be digitalized. Organisations must understand and adapt the changes. In the digital era, it is critical for organisations to adapt their procurement operation to Digital Procurement and ride on the rapid changes that are transforming industry.

Table of Contents

Contrasting Terminologies of Procurement versus Purchasing

Purchasing has been described as the process of ordering and receiving goods and services. Procurement, however, has been described as those activities to acquire goods and services.

These terminologies of Procurement vs Purchasing can perhaps be best explained using the PP Organogram, as shown in the diagram below. This article will focus on the terminology of Procurement, instead of Purchasing.

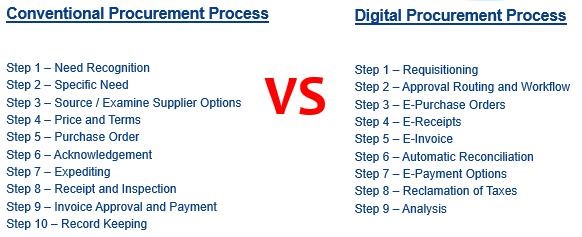

Contrasting Processes of Conventional and Digital Procurement

The starting point is to study the process of a typical conventional procurement system, and compare this with that of the digital procurement evolution. We will also explore the key benefits of transiting from conventional to a digital procurement system.

The diagram below compares the processes involving a typical conventional and digital procurement system.

Conventional Procurement Process

Step 1 – Need Recognition

This is a seemingly obvious step, but one that needs to be mentioned. A business owner (or procurement department) must recognize a product is needed in order to purchase it. That product can be either a brand new item, or one that is being re-ordered.

Step 2 – Specific Need

Does your industry have specific requirements for various products. If that is the case in your industry, be sure you are up-to-date on those requirements and order accordingly.

Step 3 – Source/Examine Supplier Options

It’s compulsory for every business to determine where to get the source of goods / parts. Comparing the price with an official quotation is necessary, the cheapest might not be the best. Lead time, delivery, design, after sales support (i.e. warranty), payment term will have to be taken into consideration during supplier selection. Some companies have practice to have an approved vendor’s list (this is a recommended practice) while others are still trying to determine who the best suppliers are. Once a supplier is chosen, companies should stick with that relationship and try to establish preferred pricing.

Step 4 – Price and Terms

Once a supplier is selected, companies should stick with that relationship and try to establish preferred pricing and specific terms (i.e. lead time, delivery, design, after sales support (i.e. warranty), payment term).

Step 5 – Purchase Order

The purchase order is the formal contract used to buy the product. The purchase order outlines the price, description, quantity, specific requirement, shipping / delivery term, lead time, currency, payment term and other terms & conditions. Once purchase order go through the internal approval process, , purchase order can be sent via fax, mail or email.

Step 6 – Acknowledgement

The transfer of the purchase order via email, mail or fax (email is highly recommended). There is necessary to get vendor acknowledgement to ensure they have received the purchase order and agree the details listed on the purchase order. Once vendor accepted the purchase order, this is a legally binding contract is formed between the two parties.

Step 7 – Expediting

This stage addresses the timeliness of the service or materials delivered. Punctuality is important is every business. Delay will cause bad impact & affect the company trust. The purchase order will have expected delivery date information. Vendor acknowledgement will also have to indicate confirm delivery / shipping date.

Step 8 – Receipt and inspection

Once goods delivered, the receiving company inspect quantity, quality; subsequently, accepts or rejects the product. Rejection is almost always due to a damaged product. Vendor will have to make up the quantity for shortage of quantity.

Step 9 – Invoice Approval and Payment

When Invoice submitted to Finance department, original invoice, receiving document (usually is delivery order) and original purchase order, this three documents must match when the seller when Finance department post it in the system. This is known as three-way matching. Once it has posted in the system, it will run and arrange pay based on the agreement payment term. If there is a discrepancy, it must be resolved before payment is made.

Step 10 – Record Keeping

The receiving (buying) company must keep good records. This means saving all relevant documents for every completed purchase. This is for easy tracking purpose for future order.

Digital Procurement Process

Step 1 – Requisitioning

Procurement system must allow electronic goods and service requisitions. The functionality must be accessible to all individuals in the enterprise authorized to make purchases.

Step 2 – Approval Routing and Workflow

Procurement system contain workflow capabilities and ability to set up automatic approval routing by good, service, dollar value.

Step 3 – E-Purchase Orders

Raise electronic purchase order using procurement software via mobile devices.

Step 4 – E-Receipts

Procurement system to automatically produce and deliver goods and services receipts upon delivery completed. To enable this function, the system need to integrate with barcode or RFID scanners to allow for automatic recognition of delivered goods.

Step 5 – E-Invoicing

Procurement system to accept and process electronic invoices. For supplier who do not have system that automatically generate electronic invoices, there’s an easy online creation through a supplier portal or document scanning.

Step 6 – Automatic Reconciliation

System that capturing purchase order, receipts and invoices automatically must also be capable of linking and reconciling.

Step 7 – E-Payment Options

Payment options of purchasing cards, electronics funds, electronic cheque and automatic cheque printing.

Step 8 – Reclamation of Taxes

Procurement system will understand the relevant taxation codes and linking into suitable tax tables to allow buyer to accurately compute tax, reconcile taxes charged by suppliers, and determine any exemptions the organization is eligible for.

Step 9 – Digital Analytics

Analysis is needed after the procurement cycles completed. There should be significantly reduce cycle time.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References:

Poh, Philip (1988), “Defining and Clarifying the use of Terminologies”, International Federation of Purchasing and Materials Management conference, Brisbane.

http://www.esourcingwiki.com/index.php/An_e-Procurement_Primer#Core_Capabilities

https://blog.procurify.com/2014/09/16/stages-procurement-process/

https://blog.procurify.com/2013/09/23/all-you-ever-needed-to-know-about-purchase-orders/

http://www.purchasing-procurement-center.com/e-procurement-advantages.html