The supply chain is key to many businesses, as it affects everything from the quality of their products to the speed of delivery to customers. Technologies such as artificial intelligence, cloud computing, and UAV technology play a very important part in today’s competitive environment. They have enabled more connectivity between employees and employers, made more information available, streamlined the storage of files, and increased the analytical power of data. This article discusses the application of several digital technologies in the supply chain sector.

Table of Contents

Artificial Intelligence (AI)

AI revolves around the use of computer algorithms and methods allowing machines to perform beyond the capabilities of humans. Now with machine learning, robots can do warehouse tasks like tracking stock inventory levels; and out-of-stock scenarios. The supply chain soon can reduce operating costs, lower risks of accidents, and waste of energy, and improve the monitoring of air quality too. Locating intelligence enables to maintain a competitive edge for operations and product delivery. AI is used to predict products that are cost-efficient to stock in a warehouse based on the nearest dispatch areas. The data graphics and behavioural information will determine what will be stocked. This enables them to adapt to changes from this information depending on shifts or other external factors.

Internet of Things (IoT)

The IoT is a network of many sensors, software, and other integrated technologies used to connect and exchange data with devices and systems on the same infrastructure. This data is processed and exchanged so companies have the visibility to monitor them in real-time. IoT is essential in the digital supply chain to increase forecast accuracy, improve inventory control, and allows a smarter transport system to be put in place. Forecasting data accuracy can be doubled by adopting IoT in a company’s supply chain. which allows data to be collected automatically through different devices. This reduces human error which enables the supply chain to come up with demand forecast data more accurately providing better customer service.

Cloud Computing Technology

Cloud Computing helps with agility, visibility, speed, and scale. Companies that use cloud computing get to rapidly scale up or down the number of computing resources, thus reducing the time, and cost of development. Deploying new applications faster and more informed decisions are made. The capability to interface with new players, greater visibility in operations, and across the full value chain. Using cloud computing is a great step toward innovation. This technology builds the foundation for affordable, unlimited access to cutting-edge technologies and capabilities otherwise will be beyond a company’s reach. When it comes to the supply chain, cloud computing plays a critical role in sustainability and accountability. This dynamic data computing enables organizations to adopt innovative technologies more quickly, reducing the environmental imprint, and enhancing resource efficiency. While being aligned with regulatory compliance and risk reduction.

Warehouse Management System (WMS)

WMS system takes care of the daily operations within a distribution center that is controlled, and managed by software, changing the way they receive inventory, store, pick up items for shipment, and know when to make a new order. It is greatly interdependent on connectivity, the software makes these processes cleaner, easier to track, and less susceptible to human error. It also offers visibility into the business’s entire inventory and manages the supply chain’s fulfillment for their operations from the distribution center to the store shelves in the distribution center. There will be a need to upgrade the WMS when there is untapped potential in their warehouse operations. The ability to capture performance and inventory metrics in real-time to understand and visualize the status plus quality of their inventory is very beneficial.

Autonomous Vehicles

Automation will lead to a truly 24/7 supply chain. As such the trucks can load, and unload, while others head out in platoons, from the same distribution center at the same time, no matter at what time. Shift workers can supervise these automated trucks and be ready to fix any problems or when programming errors occur. Autonomous trucking would not be just only a part of the supply chain where humans are not the main operators. Companies have already put autonomous forklifts and automated warehouse machinery in place, also further automation is currently being investigated. Self-driving trucks and platooning have been featured in the news lately, drawing a lot of criticism, skepticism, and concern. While few doubt that the future will bring these vehicles to the roads. Most people expect regulatory and safety issues to take some time to resolve, even though government feasibility and studies are already well underway.

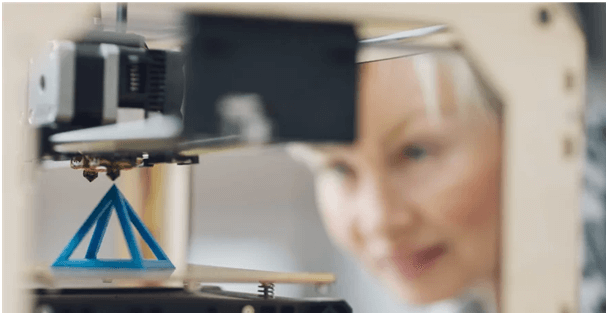

3D Printing Technology

3D printing technology gives manufacturers, businesses, and even individuals to print exact working replicas of parts or objects. It is a process whereby layers of materials are built up and create a 3D part, with minimum wastage. Most used materials are metals, plastics, and ceramics. Three methods of 3D printing are Sintering, Melting, and Stereolithography methods. The duration for 3D printing to be completed takes from minutes to days. 3D printing can be useful for industries with very complex product designs and are difficult to replicate. As technology advances, logistics providers can offer additional logistics services, if they have constantly ready raw materials, they can use a 3D printer to create the perfect product. Any industry that requires an array of parts, can take advantage of producing these parts on demand. The digital files make it easier to access globally with ease as they are readily available to print.

Unmanned Aerial Vehicles (UAVs)

UAVs are drones that are flying objects without pilots. UAVs can communicate with their human operators, and autonomous computers and operate remotely. UAVs operate with stored batteries with a combination of CCTV through computer vision, artificial intelligence (AI), and object avoidance technology. With supply chains getting more digitalized, drones or even aerial robots are fast becoming an important tool that is delivering significant value across where cost savings are vital. Drones automate job that is usually done by humans enabling operations to be performed more efficiently, productively, and cost-effectively. They also come in different sizes, functionality, mobility, capabilities, and cost depending on the work to be performed, companies can select one that matches their specifications and budget.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Karl Lee Ecijian, ADLSM. (2019). Robotic Process Automation (RPA) for Digital Warehousing. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/robotic-process-automation-rpa-digital-warehousing (Accessed: 12 June 2022).

Lew Pek Khee Mickhee, GDPSCM. (2021). Smart Technologies for A Digital Supply Chain. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/smart-technologies-digital-supply-chain(Accessed: 12 June 2022).

Sean Ashcroft, (2022). 3D printing is sustainability and agility boon for OEMs. Supply Chain Digital. Available at https://supplychaindigital.com/technology/3d-printing-sustainability-agility-boon-for-supply-chain, accessed 12/06/2022.

Siva A/L Rangasamy, DLSM. (2021). Smart Technologies for Logistics Service Providers. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/smart-technologies-logistics-service-providers. (Accessed: 12 June 2022).