The supporting vision for industry 4.0 is that all “machines” in a value chain are linked and share vital information and data based on common standards. This meant that human contribution to the process is almost zero as humans play the role of overseeing and supporting the automation. This brings forth to the existence of a smart warehouse today. A smart warehouse is an enterprise which automates workflows using the Internet, IT-system and sensor technology.

Equivalent to smart homes, a smart warehouse is equipped with various automated and interconnected technologies. These technologies work closely with one another to increase the productivity and efficiency, reducing the need for manpower and minimizing errors.Take a look at the technologies which should be considered in a smart warehouse. In no particular order, these are the seven technologies one should have access to in the warehouse today.

Table of Contents

Collaborative Robots (Cobots)

A collaborative robot is designed to facilitate human-machine interconnection and to enhance security. They are flexible, easily programmable and are specifically designed to work hand in hand with human as they have the capability to perform order fulfillment and other warehousing activities. However, while cobots can achieve what humans can do, this does not translate to putting people out of work. Cobots are designed to focus on monotonous, routine or injury prone tasks giving human associates more freedom to focus on more complex and more value-adding activities.

Hard programmed robots are not flexible enough to handle the number of unrelated tasks that crop up during order fulfillment. On the other hand, cobots can be easily programmed to accommodate for shifting of priorities within the smart warehouse vicinity. Thus, this features would significantly increase the number of tasks they can handle. The benefits of having cobots in your warehouse are as follows:

- Easy to integrate

- Creates lower and flexible capital cost

- Increases accuracy and reduces human error

- Boosts productivity level

- Enhances human labour

- Enhances warehouse personnel safety

All in all, investing in collaborative robots is a great move for companies to enhance productivity and drive efficiency in operating the warehouse.

Automated Picking Tools

In many large distribution centers, employees are required to pick and pack customers’ orders, but there is always room for human errors. At present, warehouses can benefit from near perfect picking rates when automation elements are integrated into the flow. There are a variety of automated picking tools which can be used to boost picking procedure, such as robotic order picking, pick-to-light and voice automated picking. It can be integrated flawlessly with your chosen management software for the fastest and the, most accurate automated reporting experiences.

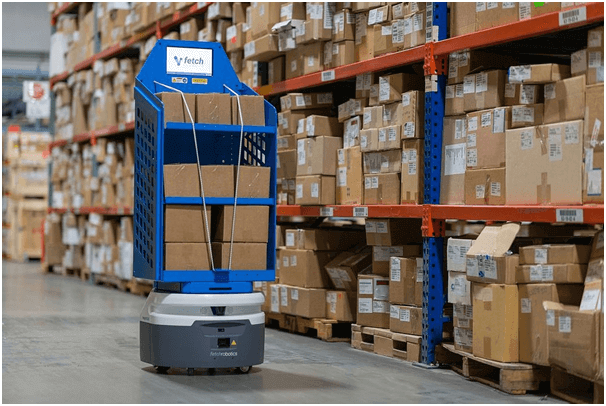

Automated Guided Vehicles (AGVs)

AGVs are material handling system that carries load and travel autonomously throughout a warehouse, distribution center or manufacturing facility. These mobile robots move by following markers or wires located on the floor or by using vision or laser. Advancement in technology over the past decades has enabled automated vehicles to be laser navigated, making it safer for human traffic with the absence of markers and wires which were potential human obstacles. Automated guided vehicles brings about many uses. These AGVs can come in many forms for human use depending on their needs and purpose. They are used as unit load handlers or forklifts, pallet trucks, used in sorting, storage and cart vehicles .Given their large verity and purpose, they are often used in manufacturing premises, and in smart warehouses which are constantly looking for an improvement in productivity and flexibility.

Automated Inventory Control

Inventory is the spark of life in a warehouse. Without comprehensive inventory control, business owners will find themselves having cash flow issue, with the inability to sustain their business. When there is a collaboration with a various technological mainstays, such as inventory tags and assets, automated inventory control platforms are implemented to eliminate labour, guesswork, and extraneous time out of the traditional inventory control. These platforms are built to automatically count the inventory and transmit live information which are precise and fast. These information can be accessed by the users remotely, making it convenient.

Artificial Intelligence (AI)

Companies are trying to use artificial intelligence enabled warehouse technology today to compete technological innovation with other companies on a level playing field. AI is an asset to the warehouse through sub-technologies such as machine learning, natural language processing, robotics and computer vision. Each function has its own uniqueness and will be discussing in the following.

Machine learning uses algorithm to make practical decisions for the warehouse. Using data gathered from sensors, it analyses the trend and recommends necessary actions such as fast replenishment of items which are nearly out of stock, shorter walking routes and better inventory positioning.Some AI features supports smart glasses technology. Natural language processing enables voice picking such that humans can operate it hands-free, allowing them to conduct other activities and more safely. These wearables are equipped with cameras that uses computer vision to recognise barcodes. Apart from using commuter vision, cameras are also placed around the warehouse to provide complete product traceability.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Hector Sunol, (2020). “Warehouse Technology: Artificial intelligence (AI)” Retrieved from CYZERG warehouse technology: https://articles.cyzerg.com/warehouse-technology-artificial-intelligence-ai, accessed 15/12/2020.

IndoSpace, (2020). “Importance of data in Warehouse Management” Retrieved from INDOSPACE a GLP joint venture: https://www.indospace.in/blog/importance-of-data-in-warehouse-management.html, accessed 15/12/2020.

John Gomez, (2020). “6 ways collaborative robots are transforming warehouse”. Retrieved from 6 River System: https://6river.com/ways-collaborative-robots-are-transforming-warehousing/, accessed 15/12/2020.

Leong Jian Jie, ADLSM (2019). “Key Digital Technologies for a Smart Warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-digital-technologies-smart-warehouse/, accessed 15/12/2020.

Marie Ann E. Dionaldo, DLSM (2020). “Automation Technologies Logistics Service Providers”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/automation-technologies-logistics-service-providers/, accessed 15/12/2020.

Stefan Karlöf, (2020). “The Smart Warehouse delivers the powerful competitive edge” Retrieved from Swisslog: https://www.swisslog.com/en-us/newsroom/news-press-releases-blog-posts/2018/10/smart-warehouse, accessed 15/12/2020.