The global demand for perishable goods, including chilled meat, continues to rise. The transportation of chilled meat by air has become a crucial aspect of the supply chain to meet this demand. There are challenges to ensure that the product reaches its destination with optimal freshness and quality. This article takes an in-depth look at the essential factors that must be considered when transporting chilled meat by air. The critical nature of temperature control and the complications of packaging results are the most important aspects. The significance of regulatory compliance like import permits, and veterinary certificates is crucial. Effective communication across the supply chain, technological advancements and the imperative of environmental sustainability are equally important.

Table of Contents

Temperature Control

Chilled meat, being highly perishable, is extremely sensitive to temperature fluctuations. Even a minor variation in temperature during transport can lead to a cascade of problems. These include bacterial growth, accelerated spoilage, loss of colour, texture degradation, and compromised flavour. The recommended temperature range for chilled meat generally ranges between 0 °C to 4 °C. It is often integrated into a refrigerated container called a Unit Loading Device (ULD). Airfreight carriers utilize advanced cooling systems that can be adjusted based on real-time temperature data. These systems maintain a consistent temperature even in challenging external conditions. The cargo hold is outfitted with advanced insulation materials that minimize the exchange of heat between the internal and external environments. This insulation helps create a buffer against temperature fluctuations caused by external factors.

Packaging and Insulation

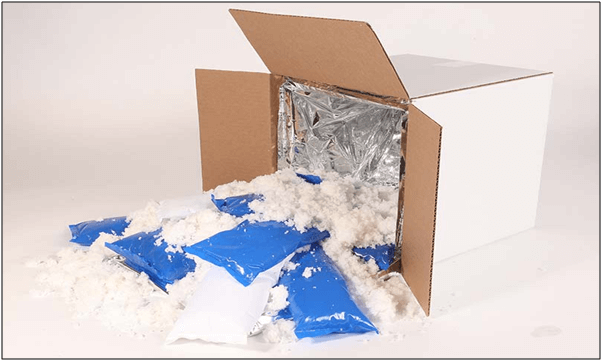

Effective packaging is not just a protective measure, it can also revolutionize how chilled meat is transported. Proper packaging can solve various challenges related to temperature control, moisture management, and maintaining the meat’s visual appeal. Active Packaging Solutions provides an interactive element within the packaging itself, which can extend the shelf life of chilled meat. By utilizing moisture-absorbing packets, Oxygen Absorbers, and CO2 Emitters, an environment with reduced oxygen levels is created. Another technique is vacuum packaging, which involves removing air from the packaging before sealing it. Insulated packaging is designed to create a barrier between the external environment and the chilled meat cargo, minimizing temperature fluctuations. Additionally, reflective films are integrated into the packaging to bounce back external heat radiation. Barrier films are also utilized to prevent the penetration of moisture, gases, and odours into the packaging. Modified Atmosphere Packaging (MAP) technique can adjust the composition of gases within the packaging to create an atmosphere that slows down spoilage.

Compliance with Regulations

The international transportation of chilled meat involves navigating a complex web of regulations and documentation requirements. IATA has specific guidelines for the transportation of perishable goods. These guidelines cover packaging requirements, temperature controls, and labelling. It is important to follow the IATA Perishable Cargo Regulations (PCR) to meet industry standards. Health and safety regulations regarding the import of food products vary among countries. Veterinary and health certificates provide confirmation that the chilled meat complies with the health and safety standards of the exporting and importing countries. Understanding and adhering to these regulations is crucial to ensure a seamless transport process. Accurate and complete documentation, including permits, certificates of origin, and health certificates, is essential for customs clearance and to prevent logistical hiccups.

Quality Assurance

Quality assurance is a critical aspect of transporting chilled meat by air. It encompasses a range of measures and processes aimed at ensuring that the meat maintains its safety, freshness, and quality all the time. Quality assurance really begins at the meat processing facility or supplier. It is essential to verify the source’s reputation and adherence to hygiene and food safety standards. This involves inspecting the facility for cleanliness, adherence to meat processing guidelines, and certification by relevant food safety authorities. Meat sourced from reputable suppliers with a strong track record is more likely to maintain its quality during transit.

Security and Handling

Ensuring the security and proper handling of meat during transit is crucial as it directly affects its safety and quality. Adequate security measures such as restricted access, surveillance cameras, and monitoring systems prevent tampering, theft, and contamination. Moreover, careful handling of the meat prevents any damage or temperature fluctuations that could affect its quality. To ensure proper security, containers and cargo doors should be secured with tamper-evident seals and locks. Similarly, meat packages and containers should be stacked correctly and securely to prevent any deterioration in quality. The shipment of meat should be strategically positioned within the cargo hold to ensure even airflow and temperature distribution. Appropriate handling equipment like forklifts or conveyor belts should be used to move meat shipments within the cargo hold with utmost care.

Communication and Coordination

Effective communication and coordination ensure that everyone involved in the process is well-informed and aligned to respond quickly to issues that may arise. Clear and reliable communication channels are established among stakeholders, including the airline, ground handlers, suppliers and customs authorities. These channels can include phone lines, email, and messaging systems. Loading, unloading, and transportation activities are coordinated to minimize delays. This ensures the meat spends as little time as possible on the ground, especially during transfers between flights. Protocols are developed for responding to unexpected situations, such as temperature deviations, equipment malfunctions, or delays. Clear communication is crucial in such scenarios to coordinate rapid responses.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.