With the emergence of ever-on e-commerce, the prerequisite for speedier responses and the need to deal with a more prominent number of SKUs with fewer blunders, warehouses need to scale up the standard to meet the necessities of a secure, perceptive and digitized warehouse. Searching ahead for the next 2 to 10 years, an anticipated increase in digital transformation preference will bring profound changes to warehouses’ operation. As needs be, it should hit its apex by embracing disruptive warehouse digitization.

Table of Contents

Costs, Efficiency and Innovation

Despite the fact that e-commerce adds multifaceted nature to warehouse operations, shorter delivery times and inventory deployment across the supply chain, including the last mile, have become the norm. Third-party logistics providers are now citing 10-20 percent rate increases for standard warehousing activities such as receiving, storing, delivery, returns, and so forth.

Expanded multifaceted nature and increasing rates represent a multi-faceted test for logistics sourcing teams. Those who lack discipline in procurement and proactive bid planning are struggling because of their inability to leverage market competition or explore alternative solutions. The focus on emerging technologies has expanded, but conventional firms under invested to improve logistic proficiency are seeing limits on cost-cutting activities and a sharper rise in warehousing costs.

A good collaborative supplier development policy is an alternative or complement to a robust bidding strategy. Regardless of the fact that it is the duty of 3PLs to invest in new productivity-enhancing technologies, partnering and insurance approaches involving cost-benefit sharing as part of the shipper-supplier relationship inspire them to contribute and invest.

Innovative and intriguingideas are often transportation and fleet focused (e.g. real-time route optimization, cauterization of cargo, autonomous trucks) but interesting concepts in warehousing and technology-driven productivity initiatives have emerged. Conventional warehousing activities are evolving drastically with the help of technology innovators and logistics leaders must stay at the forefront of these innovations.

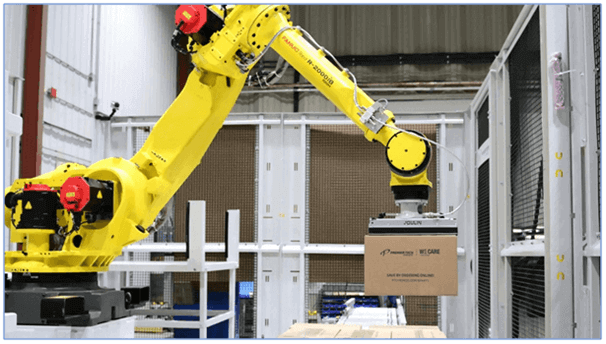

Collaborative Robots (Cobots)

The cobot or “collaborative robot” is specially designed to facilitate the human-machine interface and enhance security. These machines can likewise work with human workers in a similar zone and manage risks through their sensitivity and programming. Utilizing AI programming, programming robots would be extremely straightforward for everybody, offering significantly more flexibility than beforehand.

The picker would just need to “run” the moves to the robot once, and afterward, he could rehash it. For repetitive activities, for example, pallet loading packing and stacking, this kind of machine could be of assistance to human works. They will be particularly designed to work with and not replacing human beings. It is not generally feasible for every warehouse to adopt such innovation promptly, especially given that this requires substantial funding and changes in infrastructure. That is why ever increasing numbers of warehouses are embracing collaborative robots or cobots, autonomous elements that are worked to work with your current partners, not without them. Cobots allow warehouses to keep many of their own processes and system design choices intact while still benefiting from the streamlined workflow offered by fully autonomous components.

Radio Frequency Identification (RFID)

Radio Frequency Identification is a method of monitoring objects using digitally encoded tags and a digital database containing data on each tagged object. RFID technology is similar to barcoding, however, unlike reading barcodes, the RFID reader (interrogator), uses radio waves to locate tags and does not need to have the tag right in front of it to scan. In reality, the tag does not even need to be in the reader’s sight line. Several RFID tags can be read simultaneously as compared to barcodes read each in turn.

Autonomous Mobile Robots

AMRs can be configured to be placed in different sections of the warehouse, depending on how much they are required. So, fast-moving items that need to be taken to a human order-picker more often than not would be placed nearer to the pick-up station. And, apparently, items that sell less often will be kept further away.

In fact, AMRs know when to get to the charging point and power up – they don’t need to be sent or taken manually. These are only two instances of what computing can do about it. They are described as “artificial intelligence,” but whatever it is called, many other innovations that make AMRs even more autonomous are likely to emerge.

Drone – Unmanned Aerial Vehicles (UAVs)

The use of drones in the warehouse will vary depending on the operation. However, listed below is the typical rundown of the work that your flying robotic co-worker is going to do.

- The drone is responsible for counting the inventory number of Items, which is contained in the boxes stored on the racking of the warehouses.

- The Warehouse Management System (WMS) is fully integrated with the drone software. From this, drones can access inventory location data down to a precise aisle, rack, or bin level.

- Drone maps the optimal route to a stock location with an optical system that combines computer vision and profound learning technology, a sub-field of artificial intelligence learning that empowers the recognition of images based on a network of learning layers.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Borisova V., Taymashanov K., Tasueva T. (2019). “Digital Warehousing as a Leading Logistics Potential”. Retrieved from Springer Nature Switzerland AG 2019 https://link.springer.com/chapter/10.1007/978-3-030-15495-0_29, accessed on 17/06/2020.

Hector Sunol. (2020). “Warehouse Digitization – The Future of Warehousing”. Retrieved from https://articles.cyzerg.com/warehouse-digitalization-the-future-of-warehousing, accessed 17/06/2020.

Leong Jian Jie, ADLSM. (2019). “Key Digital Technologies for a Smart Warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-digital-technologies-smart-warehouse/, accessed 17/06/2020.

Mai Tao. (2019). “Warehouses becoming more flexible through the use of robotics” Retrieved from https://roboticsandautomationnews.com/2019/09/23/warehouses-becoming-more-flexible-through-the-use-of-robotics/25168/, accessed 17/06/2020.

Marvin Edward, DLSM. (2019). “RFID Technology for Orthopaedics Warehousing and Distribution”. Retrieved from https://publication.sipmm.edu.sg/rfid-technology-orthopaedic-warehousing-distribution/, accessed 17/06/2020.

Michael Zimmerman, Alberto Oca, and Akash Agrawal. (2019). “Acceleration in Warehousing Costs Shaping Greater Efficiency and Technology Innovation”. Retrieved from https://www.supplychain247.com/article/acceleration_in_warehousing_costs_shaping_innovation, accessed 17/06/2020.

Naresh Kumar. DLSM (2019). “Digital Technology for Warehouse Productivity” Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-warehouse-productivity/, accessed 17/06/2020.

Shankar Kumar. DLSM (2019). “Technologies for more Productive Warehousing”. Retrieved from SIPMM: Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-more-productive-warehousing/, accessed on 17/06/2020.