Sourcing for mining and natural resources, where regulatory compliance and product quality are top priorities, increasing value without compromising service levels is crucial. The lowest cost option is not always the best choice. The strategic sourcing initiatives help organizations to analyze current spend against the marketplace, spend analysis, or benchmarking to identify practical and beneficial savings opportunities.

In addition to cost reduction, the service level increases and develop long-term supplier relationships. Having a healthy supplier relationship is also crucial since innovation is a key importance to the mining and natural resource industry. Working towards the strategic supplier partnership will benefit organizations in many resources such as securing exclusive rights to the supplier’s improved technology and practices; sharing environmental management techniques and knowledge; provide solutions to deal with materials used in the mining processes, and discussing on such imperative issues.

Handling and transporting regulatory body’s certification for mines, when engaging such suppliers in early material planning discussions, help them clearly understand the requirements and to avoid delivery/transportation delay.

Table of Contents

Procurement of Conflict Minerals

Raw materials such as tin, tantalum, tungsten, and gold (3TG), that covered under the EU ‘Conflict Minerals’ Regulation 2017/821, will be badly impacted by companies imported these minerals for producing mobile phones, technology, automotive products, as well as jewelry or medical devices.

These regulation aims to stop the financing of armed groups in developing countries through the trade of 3TG and ensure that the vast majority of these minerals imported are sourced responsibly. It also an efforts to stop human rights abuses and armed conflict financed by trade in minerals.

To achieve a Conflict-Free-Raw Material Procurement, companies are to procure their raw materials from an officially certified and government-approved mines from the regions. They are to adhere strictly to the process of EU and international guidelines on the raw materials. Be more transparent by documenting the source and chain of custody conflict minerals accordance with OECD (Organization for Economic Co-operation and Development) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas.

The five-step framework are as follows:

1. Establish Strong Company Management Systems

2. Identify and Assess Risks in the Supply Chain

3. Design and Implement a Strategy to Respond to Risks

4. Conduct Third-Party Audits of Supply Chain

5. Report on Supply Chain Due Diligence

Integrating Technologies for Effective Procurement

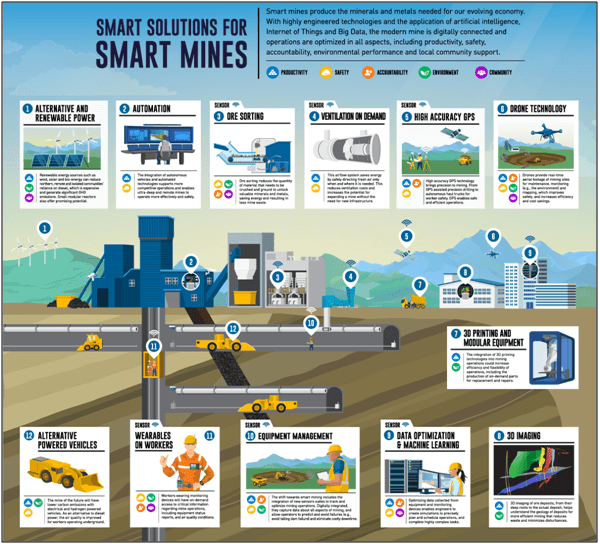

The future mining industry needs in the digital age, transforming mining systems through integration of advanced technologies, and how to best achieve operational excellence with cost-competitive, safe and environmentally responsible operations. Mining production is vital for global socio-economic development but faces a variety of challenges, ranging from deeper ore bodies and lower grades to other various social and environmental issues. Create new ways of thinking, and research culture and approaches toward integrating advanced technologies such as automation, communication, smart data management and importantly the efficiently extracting of mineral resources.

Deploying the latest in sensor and cloud technology, connected these mines in the improving extraction process and workers’ safety while boosting its productivity. A connected mine uses data from sensor technology to effectively manage underground and pit mining operations. From a single application on a mobile device, employees at mine sites can now receive alerts via SMS, email or in-app notifications that help them to react efficiently in real-time problems critically and maximize productivity. In addition, advanced data analytics can be applied to raw data to create insights, visualizations, and recommendations. Allowed employees to stay connected to the surface from accidents and breakdowns, and streamlines operations in real-time.

Over time, the technologies will reveal insights that could help develop sustainable mining operations, creating new opportunities for a tech-savvy generation and minimizing their negative impacts. Mining companies will be able to responsibly deliver the materials to the modern world needs, benefits environmental and cost-saving.

Eco-innovative Practices of Mineral Products

Eco-innovative is the development of products and processes that contribute to sustainable development; offers something very different, a new technological direction and environmentally kind solutions to existing mineral products. It may require a change in patterns of production and consumption. The environmental dimension in the production or design of the mineral product, being supposedly greener than the alternative. The production method in itself need not be cleaned.

Produce High-Yielding Fertilizer instead of synthetic fertilizers (by Plant Nutrition Technologies) is one of the eco-innovative mineral products in the market. To help farmer reduce the input of synthetic fertilizers, it produces from raw materials left from the mining eras with a combination of the natural elements to create a soil bio-mineralizing and regenerative fertilizer. Microbes from this fertilizer inhabit the soil, reach directly into the root system and provide better nutrition than synthetic fertilizer which has long-term negative effects such as damages the natural makeup of soil and water pollution from the increasingly toxic groundwater caused by synthetic fertilizers.

Managing End-of-life Mineral Products

It is nearly impossible even for the most sustainable mineral products system to consume all it inputs or reuse all its wastes before leaving a facility, there will still be a need for End of Life (EOL) initiatives for external recycling and waste recovery to be implemented. The EOL practices include the reverse logistic where all the mineral wastes will go to the recovery activities, whereas the remaining wastes as EOL practices. All the remaining wastes are to be identified (hazardous and non-hazardous wastes) for proper disposal to minimize the environmental effect and to compliance with local regulation. All regulated waste is disposed of by an authorized service provider.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

American Manganese Inc. (2019). “Making Lithium-ion Last Forever™”. Retrieved from https://americanmanganeseinc.com/, accessed 19/06/2019.

Corcentric Source One Management Services. (2018). “Strategic Sourcing for Mining and Natural Resource Companies”. Retrieved from https://www.sourceoneinc.com/industries/sample-industries-served/mining-and-natural-resources/, accessed 13/06/2019.

European Commission. (2017). “The regulation explained”. Retrieved from http://ec.europa.eu/trade/policy/in-focus/conflict-minerals-regulation/regulation-explained/, accessed 14/06/2019.

Heidi Vella (2013). “Green technologies: making mining more sustainable and energy-efficient”. Retrieved from https://www.mining-technology.com/features/feature-green-technologies-sustainable-energy-efficient/, accessed 20/06/2019.

Mickie Foong, PDPM. (2019). “Key Considerations for Sustainable Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-sustainable-procurement/, accessed 19/06/2019.

National Environment Agency. (2019). “Categories of Waste to be Controlled- Waste Stream” Retrieved from:

https://www.nea.gov.sg/our-services/pollution-control/chemical-safety/multilateral-environmental-agreements/list-of-wastes/annex-i, accessed 19/06/2019.

Nicholas LePan. ( 2019). “Visualizing the Potential of Smart Mining”. https://www.visualcapitalist.com/potential-smart-mining/, accessed 20/06/2019.

Philippe Delcourt and Bart Vercauteren. (2018). “EU Conflict minerals regulation: implications and lessons learned from the Dodd-Frank Act in the US”. Retrieved from https://www2.deloitte.com/be/en/pages/energy-and resources/articles/responsible-supply-chain—minerals-sourcing.html, accessed 13/06/2019.

Simone S. and Fernando B. (2016). “Sustainable practices and eco-innovations adopted by industrial companies”. Retrieved from https://www.researchgate.net/publication/306523857_Sustainable_practices_and_eco-innovations_adopted_by_industrial_companies, accessed 18/06/2019.

Stephanie Metzinger. (2017). “FROM MINE WASTE TO SOIL GOLD: Firm Delivers High-Yielding Fertilizer”.

Retrieved from https://www.wga.com/magazine/2015/11/12/mine-waste-soil-gold-firm-delivers-high-yielding-fertilizer, accessed 18/06/2019.

Visual Capitalist. (2019). “Climate-Smart Mining: Minerals for Climate Action”. Retrieved from https://www.visualcapitalist.com/climate-smart-mining-minerals-for-climate-action/, accessed 20/06/2019.

Winky Lim, ADPMM. (2017). “Ensuring Sustainable Practices in Procurement for Effective Supply Management”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/ensuring-sustainable-practices-in-procurement-for-effective-supply-management/, accessed 20/03/2019.