Maintenance, Repair, and Operation (MRO) supplies can constitute a substantial part of the purchases by an organisation. Thus, a concerted effort is needed to reduce the non-valued cost, and improve the profitability of an organisation. This article explores seven strategies to reduce the cost of MRO supplies in an organisation.

Table of Contents

Strategy 1: Analysing The Spend

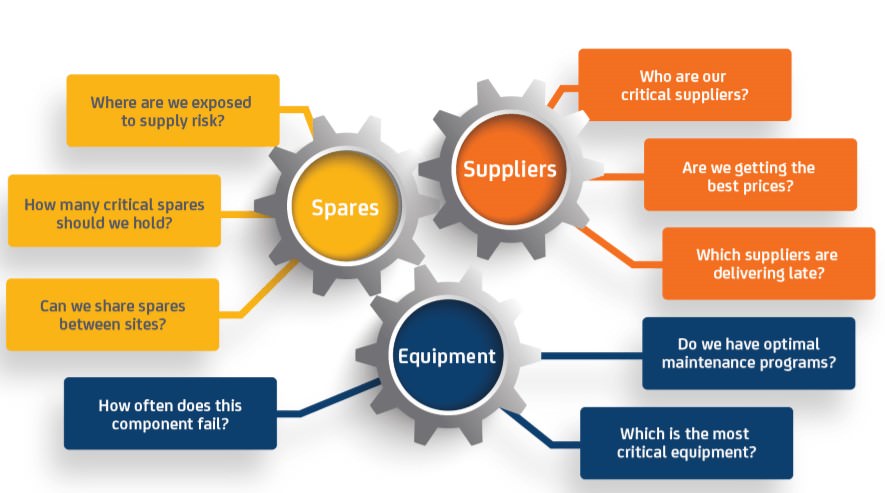

A thorough analysis of an organisation spend will allow it to determine what it buys, how much it is paying and who is getting most of the dollars. Performing this analysis is challenging and will take the efforts of not only the procurement team but also stakeholders from each business group it serves.

Data collection is the most time-consuming element of the task and can be frustrating. But it is critical to the success of the initiative. Stakeholders cannot easily make decisions, eliminate inefficiencies or improve performance without knowing what, where and how MRO categories are purchased.

In order to compile an 80 percent representation of the category spend in one consolidated format, the following data must be included: manufacturer name, manufacturer part number, estimated annual usage and package quantity.

In addition, most buyers are managing multiple sites that are buying MRO items and should provide delivery locations, acceptable substitutes and historic unit pricing. An incomplete data set is likely to force suppliers to provide substitute products and hedge on pricing due to lack of detail.

Strategy 2: Choosing the Right MRO Supply Model

MRO model selection has probably one of the biggest impacts on future spend, and hence it is a critical lever to consider. There are primarily three supply market models for MRO: the Specialist model, the Integrator model, and the Hybrid model.

The Specialist model involves choosing specialist distributors for each sub-category. The Integrator model involves outsourcing all spend to one primary distributor who will either self-service all demand and/or utilize third party distributors for items they cannot supply. The Hybrid model involves consolidating most categories with general distributors, but using specialist distributors for technical categories or niche supply requirements.

When it comes to selecting the MRO model, one-size does not fit all. Each model has its pros and cons. Companies that have sizeable spend on technical categories such as pipes or valves may benefit from the Specialist or Hybrid models due to better service and pricing received from specialty distributors. Companies that incur majority spend on non-technical categories such as industrial supplies may benefit from Integrator model due to volume leveraging.

Strategy 3: Price Transparency across All SKUs Purchased

A common challenge within MRO category is managing pricing for the huge number of SKUs purchased each year. Moreover, there is also a large percentage of SKUs that are bought new each year. For a large scale manufacturing company, it is common to see 30%-40% of spend being purchased as new spend (spot spend) where buyers do not have the benefit of pre-negotiated pricing.

To overcome this challenge, companies must first identify their core SKUs (those accounting for at least ~70% spend and are recurring purchases). For these core SKUs, companies can request preferred suppliers to offer competitive and transparent discounts/mark-ups and special pricing. These SKUs can be locked-in the contract upfront to ensure competitive pricing for end-users. For spot spend, companies can negotiate discounts off supplier list prices or fixed mark-ups. Although these discounts/mark-ups may not be as competitive as core SKU pricing, it will still ensure that companies are receiving leveraged and transparent pricing overall.

In addition to SKU pricing, companies should also consider receiving volume incentives from preferred suppliers to ensure benefits are realized from growing the annual program spend with preferred suppliers.

Strategy 4: Changing The Sourcing Strategy

By aggregating spend across multiple sites you can effectively drive standardization and consolidation of your current supply base. This requires pulling in the spend that currently resides outside of procurement and may inevitably involve conflicts, since local sites that have been purchasing individually may have long-term relationships that offer favourable pricing. By grouping the business in order to allow local suppliers to participate, you can minimize tensions and help build support for the change in strategy.

MRO supplies can be divided into a hierarchy of categories for supplier selection and management. Rather than implement a separate supplier for each category of filters, gaskets and welding supplies, you may be able to take advantage of several industrial distributors that have the ability to supply across multiple product families through local distribution centres. This will allow for lower delivery costs and more frequent shipments of smaller quantities.

Smaller shipments have an impact on inventory carrying costs and will satisfy a just-in-time (JIT) inventory model. If a single supplier is not possible, then moving to the fewest number of suppliers while maintaining part coverage is the next option as long as delivery and quality standards can be met. With either strategy, distribution costs will be compressed and long-term cost reductions leveraged through product standardization and the use of alternatives.

Strategy 5: Tightening Contract Compliance

Maverick spend on services is typically 40 percent higher than it is for other indirect goods and 200 percent greater than direct goods. Enterprises report that procurement professionals use 20 percent more suppliers to source services than they do to buy indirect goods and 200 percent more than the pool they tap to source direct goods. In many cases, administrative changes, such as invoicing and supplier reduction, not price, will have the greatest impact on your total cost.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.