Table of Contents

What is Artificial Intelligence?

Artificial intelligence (AI) refers to simulated intelligence in machines. These machines are programmed to “think” like a human and mimic the way a person acts. The ideal characteristic of artificial intelligence is its ability to rationalize and take actions that have the best chance of achieving a specific goal.

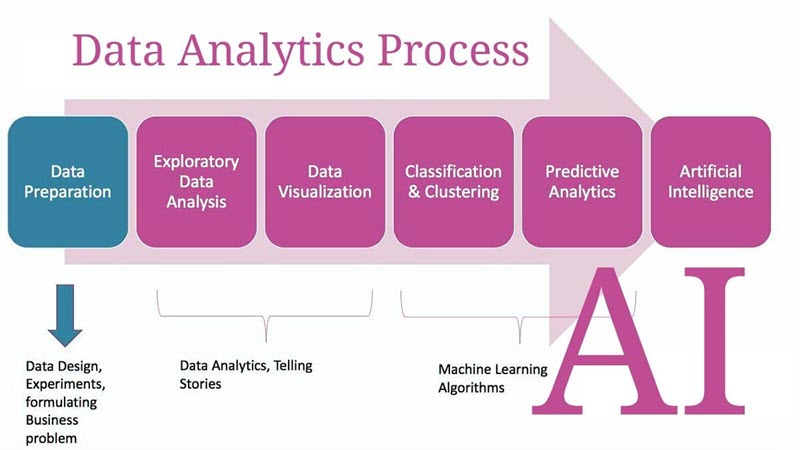

Machine Learning (ML), a branch of AI, is not programmed to do a task; it is programmed to learn. Data analysts teach the computer using data samples and by correcting the AI’s mistakes. Alternatively, the machines learn from historical data to build a model that it applies to any new data with which it is presented

New Capabilities with Artificial Intelligence

AI is coming of age as one of the main technological drivers of today’s transformed procurement organizations. With AI-derived analytical power, procurement professionals can unlock valuable insights from data and realize unprecedented efficiency and effectiveness throughout the organization.

1. Sourcing

Sourcing using AI, combined with machine learning, can transform sourcing events by helping with tasks such as defining the correct “request for proposal” type; identifying appropriate suppliers to participate based on commodity category, region, or industry; and delivering intelligence on market signals and pricing pressures to optimize results.

2. Contract and Supplier Management

Contracting can also become smarter and more comprehensive with applications that automatically identify relevant terms and conditions matched to legal library and taxonomy, uncover similar contract terms for a specific commodity by industry or region based on benchmarking data, and suggest optimal prices to target based on expected volume and contractual discounts.

When a supplier’s performance drifts out of alignment with the contract, the AI-based software can let you, and the supplier, know right away. No number crunching and no time-consuming surveys. AI can also be used to help make sure your organisation better manage supplier relationships ensuring that invoices are ready to be paid on time, based on their specific payment terms.

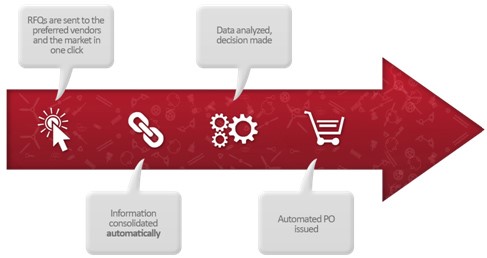

3. Order Processing

When the software knows who you are and what you are permitted to order, your requisition becomes an order and a fulfilled delivery with a single click. Only the most exceptional cases need the professional’s personal attention.

4. Risk Management

Buyer can also integrate financial risk scores, sustainability and corporate social responsibility (CSR) scores and similar third-party data sources related to risk.

With this information, procurement can enrich a spend analysis process to see not just how much it spent with a supplier but also whether that spend is in jeopardy because the supplier is teetering toward bankruptcy, or could balloon because the supplier is based in a politically unstable geography, or is tied to an environmentally harmful production process.

Challenges and Risks

To realize the greatest opportunities in the evolving AI procurement marketplace, leaders must evaluate the following factors:

1. Analytic Integration

Artificial Intelligence quickly moving toward the ability to independently make decisions raises concerns over control, accountability and trust. Who will be responsible if AI makes a bad decision? If AI procurement begins guiding controversial management decisions, then it will be important to understand exactly how and to what extent spend data should inform executive decision making. Moreover, people should demonstrate critical thinking and have the final say.

2. High Cost

Another challenge is the necessary investment in developing AI, and it is not programming machines to learn that represents the largest investment. In fact, it is the cost of gathering and obtaining enough data to train the machine that often has an enormous cost. The more data there is, the better the learning phase will be. Furthermore, the qualitative aspect is as important as the quantitative one because learning from bad data will lead to poor results.

3. Supply Network Harmonization

To what extent do suppliers and partners have the ability and willingness to provide or interface with cognitive procurement, instead of human employees? If there are infrastructural or cultural barriers that make automated communication or data transfers difficult, then it will be important to understand what the risks and opportunities that exist along the way to transforming an enterprise’s digital supply network.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References:

Bertrand.M (2017) ‘Cognitive Procurement – What are the implications?’

Retrieved from: https://www.ibisworld.com, accessed 18/11/2017.

GEP (2017) ‘Artificial Intelligence and Procurement’.

Retrieved from: https://www.gep.com, accessed 18/11/2017.

Prashant.V (2017) ‘Procurement beyond RPA’.

Retrieved from: https://www.edgeverve.com, accessed 03/12/2017.

Wax Digital (2017) ‘Emerging technology that can change the way procurement works’. Retrieved from: https://www.waxdigital.com, accessed 11/11/2017.