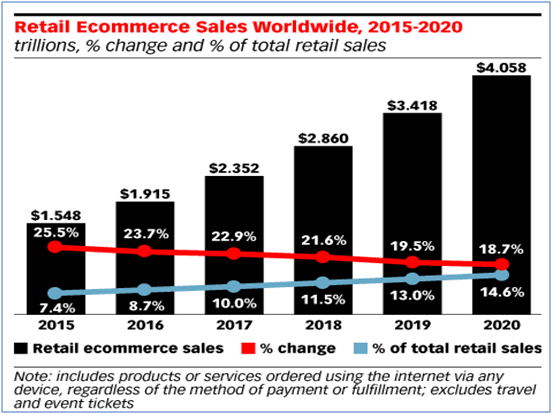

Nowadays, as trends shift from Ecommerce to Digital Commerce, more Ecommerce companies are now integrating strategies such as Omni-channel, exploiting social media and other consumer-facing technologies for effective and integrated marketing for their businesses. This has in turn, significantly impacted E-tailers in terms of their logistics practices for their warehouses.

According to estimates by Temasek and Google, the Ecommerce market in Singapore alone is expected to be worth US$5.4 billion by 2025. Coupled also with the rise of a consumerist appetite amongst the middle class in countries such as China, India and Indonesia, Digital Commerce is only going to expand further in the future. E-tailers, therefore feel more compelled to direct their focus through effective Logistics.

The following highlights some ways of integrating logistics practices in the warehouse.

Table of Contents

1. Implementing an Effective Picking strategy

Basically, there are seven picking methods that companies may implement.

• Discrete Order Picking

A simple picking method where one order picker picks one order, one line at a time. Orders are not scheduled and can be picked at any time on a particular day.

• Zone Picking

This is also known as the “pick and pass” method where order pickers are assigned a specific and physically defined zone in the pick area. The picker that is assigned to each zone is responsible for picking all of the SKUs located in the zone for each order.

• Batch Picking

It is when one picker picks a group or batch of orders at the same time with one SKU at a time. This is advantageous as travelling time is reduced or when there are multiple orders with the same SKU.

• Cluster Picking

It is a method of picking into multiple order containers at one time. The containers could be totes containing order batches or discrete order totes.

• Wave Picking

A method that is pretty similar to discrete picking in that one picker picks one order and one SKU at a time. Orders may be scheduled to be picked at specific times of the day to coordinate and maximize the picking and shipping operations.

• Zone-Batch Picking

It is a combination of methods where pickers are assigned a zone, just like traditional zone picking and comes with a scheduling window. However, pickers are also directed to batch pick within their zone.

• Zone-Wave Picking

This is a combination of methods in that pickers are assigned a zone. Each picker within their zone will pick all of the SKUs for all orders that are stocked in their zone, one order at a time with one scheduling window per shift.

• Zone-Batch-Wave Picking

Probably the most complex combination out of all picking methods. “Each picker is assigned a zone and picks all SKUs for orders stocked in the assigned zone.” Additionally, the picker picks more than one SKU at a time with multiple scheduling windows per shift.

2. Develop an All-purpose Facility that “Talks” to One Another

Emphasis should be placed on creating an all-purpose facility to handle small, medium and large orders that can do “it all” in an accurate manner. Firms would like to consider using IT-enabled systems and Distributed Order Management (DOM) solutions at both the distribution and the retail levels to ensure smooth and seamless processes to and from those all-purpose warehouses and Distribution Centres (DC). The ideal goal is to try to ship inventory from any point, stores included so that companies can accurately maintain inventory accuracy in a cohesive manner. It is suggested to do it all in one place (i.e., the warehouse) and not at the store and be able to do it all at once.

3. Design Facilities with Omni-channel in Mind

Omni-channel has nowadays provided customers with a seamless shopping experience. Be it shopping online from a desktop, mobile device, telephone or in a physical store, etc. It has transcended the modern-day supply chain and is impacting the way organizations design their warehouses and DCs. For example, having a DC that handles direct to consumer (D2C) Ecommerce can actually benefit from wholesale distribution in the short term under a single roof. In this way, it creates maximum value from its automation and available labour force.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.