One of the most significant revolution of the logistics industry is the emergence of a new generation of logistics service providers, called fourth party logistics (4PL).The 4PL involves not only the management of a client’s supply chain, but also the development and improvement of their supply chain strategy. 3PL service providers offer far more tactical services (Hickson et al., 2008, p. 11).

Their function is to provide the supply chain members with a customized service, based on a flawless coordination of logistical resources mobilized from the various firms. 4PLs can be considered as asset-free logistics middlemen offering expertise for the establishment and control of complex logistics systems, including logistics consulting and the organization of information infrastructure, transport, logistics as well as financial services that are needed”. (Schramm, 2012, p. 154).

This article suggests the following key success factors for 4PL service providers to manage logistics more effectively.

• Latest IT infrastructure

• Better strategy for planning and execution of logistics

• Industry-specific expertise

• Enhanced integration of supply chain capabilities

Table of Contents

Latest IT infrastructure

Buyers prefer service providers who not only track and report on the flow of goods and services but also capture real-time data with minimal disruptions in the network. All this is possible only if the suppliers have updated their infrastructure with the latest developments in the IT industry.

The advanced technology used by 4PL service providers makes the entire flow of the supply chain seamless. The technology makes it easier for suppliers to connect across global networks and provides better management of information. It also gives the appropriate risk weights, to ensure the safety, quality and reliability of the whole chain.

Benefits of IT application:

o The Ability to Integrate Multiple Platforms

Previously existing boundaries that prohibited fast communication and order fulfilment have become obsolete, allowing for more effective and efficient integration between parties.

o Greater Security

With advances in technology come advances in privacy, allowing companies to provide guarantees regarding information given to them. Logistics and Supply Chain providers can implement great security measures and practices to the forefront of their operations.

o Reduced Costs

One of the greatest benefits of implementing technology into business practices is the money it can save on operational costs. A computer or machine can now carry out tasks that were traditionally completed by a worker.

o Ease of Scalability

Since the use of technology can help to spearhead supply management providers in their own market, it can also be used to assist in the event of rapid scalability. With increasing demand for products comes an increase in the need for logistics. Technology can greatly assist with each additional order and the inevitable strain of processing that comes with it. The infinite capabilities that technology provides can allow a provider to extend their terms within minutes.

o Removal of Geographical Boundaries

Throughout time, geographical barriers have existed within the logistics and supply chain industries. However, technological advances have removed physical boundaries from this perspective, allowing for greater amounts of transparency within warehouse distribution.

Better strategy for planning and execution of logistics

Logistics is not confined to tactical decisions about transportation and warehousing. Logistics strategy is the set of guiding principles, driving forces and ingrained attitudes that help to coordinate goals, plans and policies between partners across a given supply chain (Mohamed Hardi bin Abdullah, GDLM, 2018). Strategic logistics plans define how a business plans to deliver products or services to customers. While every company has different needs, looking at logistics plan examples help business owners develop the right strategy for business development.

Warehouse Strategies

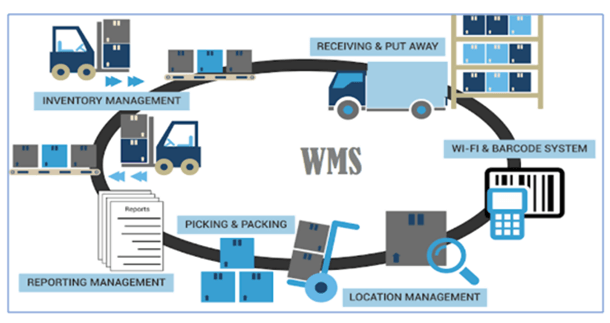

A warehouse management system (WMS) is a software application, designed to support and optimize warehouse functionality and distribution centre management. Today, warehouse managers have a wide array of technologies to choose from as they strive to reduce costs, improve efficiency and streamline operations. They must ensure that goods, materials, and products flow effortlessly by optimizing their warehouse operations using warehouse technologies (Eddie Kek Chun Beng, ADLSM, 2019).A WMS uses a database configured to support warehouse operations, containing variety of standard warehouse elements such as individual stock keeping units (SKUs) that are handled and stored, e.g., weight, dimensions, case pack, automatic ID labels (bar codes), and inventory by location with manufacture date. This includes warehouse storage locations, and dock doors (e.g., individual number), as well as expected labour productivity rates by function or activity (e.g., cases picked per man-hour). The flow chart below shows the feature of WMS.

Transportation Strategies

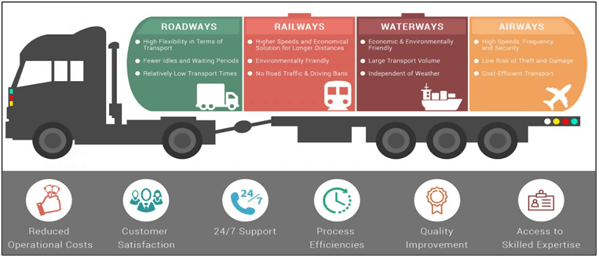

Transportation is a key factor in determining an organization’s overall logistics costs. Not every company has large transportation needs, whereas others rely on transportation as the cornerstone for accomplishing business goals and product delivery. Transportation includes short- and long-distance trucking options, air transportation, shipping through ports and trains. There may be times where transportation strategies include several different transportation options.

Industry-specific expertise

For a 4PL service provider to be successful they need to have expert solution and in-depth knowledge of focused industries, get to know the challenges of the buyer’s industry’s supply chain and how to tackle them. This enable them to design, implement and manage solutions for the buyer’s company’s needs, faster and more efficiently.

o Aerospace

Best components availability and minimum inventory through lean transportation management must be tailored to inbound, outbound and aftermarket of upstream tiers, airframers and airlines. They include inbound to factory, aftermarket spare parts, and inflight logistics.

o Automotive

Rationalised global supply chains as a result of real-time dynamic transportation management and visibility to solve the most complex inbound, inter-factory and distribution challenges of upstream tiers and car manufacturers considering regional constraints.

o Retail

Integrated Logistics offers solutions to create durable cost and cash savings while improving delivery performance to increase competitiveness, responsiveness and end customer satisfaction. They include inbound to factory, and end-to-end logistics management.

o High-Tech

End-to-end supply chain optimisation facilitated by a global Logistics Control Centre infrastructure, enabling and orchestrating the perfect collaboration of all involved supply chain partners. This allows clients to reduce inventories, lower distribution costs and speed up new product market introductions. They include direct ship and reverse logistics.

o Industrial

Solutions reducing complexity and total cost while increasing on-time-in-full performance and creating end-to-end visibility. Our organically grown infrastructure constitutes an ideal backbone to further rationalise and standardise global operations, enabling agile operational decisions. They include inbound to factory, intra-plantlogistics, and outbound to end customer.

o Pharma & Healthcare

The offering focuses on diagnostics and pharmaceuticals. It enables companies to improve their level of regulatory compliance, to protect goods and to achieve synergies through collaboration. They include primary distribution.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Eddie Kek Chun Beng, ADLSM. (2019). “Digital Technology for Effective Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-effective-warehousing,accessed 08/09/2019.

Hickson, A., Wirth, B. & Morales, G. (2008). Supply Chain Intermediaries Study. University of Manitoba Transport Institute, 1-50.

Mohamed Hardi bin Abdullah, GDLM. (2018). “Autonomous Trucking in Logistics Transportation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/autonomous-trucking-in-logistics-transportation, accessed 08/09/2019.

Powell, T. C., and Dent-Micallef, A. “Information Technology as Competitive Advantage: The Role of Human, Business and Technology Resources,” Strategic Management Journal (18:5), 1997, pp. 375-405.

Schramm, H.J. (2012). Freight Forwarder’s Intermediary Role in Multimodal Transport Chains – A Social Network Approach, Physica Verlag, Springer Company, Vienna.