Every decade or so, the business world invents another term for how it extracts managerial and decision-making value from computerized data. In the 1970s the favored term was decision support system, accurately reflecting the importance of a decision-centered approach to data analysis. In the early ’80s, executive information systems were the preferred nomenclature, which addressed the use of these systems by senior managers. Later in that decade, emphasis shifted to a more technical-sounding online analytical processing (OLAP). The ’90s saw the rise of business intelligence as a descriptor.

It appears, however, that another shift is taking place in the label for how we take advantage of data to make better decisions and manage organizations. The new label is analytics, which began to come into favor in the middle of this century’s first decade at least for the more statistical and mathematical form of data analysis.

Table of Contents

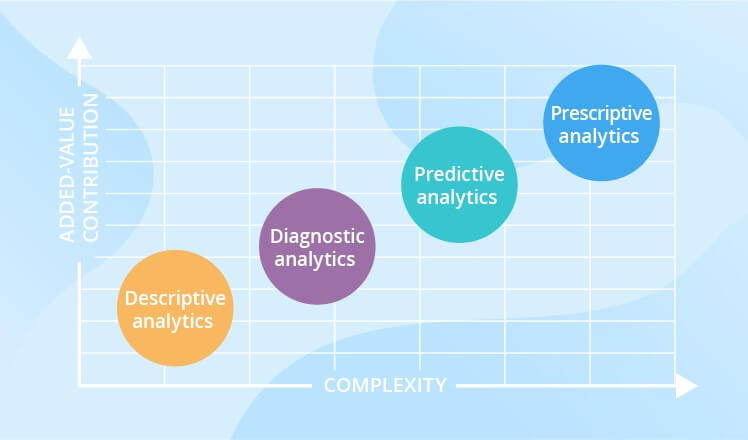

Types of Data Analytics

o Descriptive Analytics (What is happening in the business?)

o Diagnostic Analytics (Why did it happen?)

o Predictive Analytics (What will happen?)

o Prescriptive Analytics (What should we do?)

Descriptive Analytics

Descriptive analytics is the interpretation of historical data to better comprehend changes that have arisen in a business. It uses data aggregation and data mining to furnish insight into the past and answer: “what has happened?” It is comprehensive, precise, live data and effective visualization. Common examples are company reports that simply deliver a historic review of a company’s operations, sales, financials, inventory, customers, and stakeholders.

Diagnostic Analytics

Diagnostic analytics is less attentive on what has occurred but rather focused on why something happened. It is categorized by techniques such as drill-down, data discovery, data mining and correlations to dive deeper at the data to understand the root causes of events and behaviours; ability to segregate all perplexing information. An example is how a company can drill the inventory down to aging days categories to find out why these aging inventories are not delivered to customers.

Predictive Analytics

Predictive analytics is about analysing what the user has done historically, in order to make sound decisions about what they will want next. It uses the verdicts of descriptive and diagnostic analytics incorporate with statistical models and forecasting techniques to provide the company with actionable insights based on data as well as to predict future trends. An example is the demand forecasting trend. It is essential to note that forecasting is just an estimate and its accuracy depend highly on the data quality and constancy of the situation. Thus, the company must set an acceptable accuracy bandwidth.

Prescriptive Analytics

Prescriptive analytics is the last phase of business analytics, which also comprises descriptive and predictive analytics. It uses optimization (example business rules) and simulation algorithms to advocate what actions to take to eradicate a future problem or take full advantage of a promising trend. An example is optimized production planning and inventory in the supply chain to make sure the company can deliver the right products at the right time and optimizing the customer experience.

Cost Management in Cold Chain Analytics

Cost management is the process of effectively planning and controlling the costs involved in a business. It is considered one of the more challenging tasks in business management. Real-time information helps to establish benchmarks, optimize processes to lower costs.

The data collected can allow cold chain a focal point to help make educated, well informed decisions, which can lead to a more cost-effective supply chain. Cost management can be breakdown into three parts: Inventory cost, Operating cost and Management cost.

Inventory cost are cost associated for keeping and ordering of goods. Operating cost is the expenses of a business such as device, equipment, manpower and facility. Management cost is to organize and coordinate to achieve a business objective. With data analytics, it allows the management to make real time decision and understand current business situation to better business operation and assumption. Example: Data analytics in management cost allow a more realistic prediction into future costing and budgeting.

Resource Management in Cold Chain Analytics

It is the process of using company’s resources in the most efficient way to produce the highest quality outcome. It consists of three types of resources: Manpower, Machine and Material. Overproducing or producing at the wrong time (when consumer demand is not there) will impact the profitability of a company.

With data analytics, it helps the company to understand what is the current business demand, identify demand trend and assumption to allow better resource deployment and solution. Before a product makes it to the supplier, it moves along a line of suppliers that specialize in transportation, third-party logistics, packaging, etc.

Data analytics empower company with real-time information and assess into supply delays, wrong deliveries, and other interruptions so that resources can be redeployed effectively as require by the business demand.

Process and Quality Management

It is used to measure, monitor and control business activities that ensure it meets operational, financial and legal goals. It consists of three types of processes: warehousing, delivery and administrative process. Data analytics is part of the continuous process of real time tracking of orders and shipments. It provides the exact location of packages for incoming supplies to outgoing orders which is crucial to supply scheduling and logistic service to customer.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.