The geopolitical war, inflation, and a global pandemic such as COVID-19 have negatively impacted the environment, as well as humans. The network supply chain has grown increasingly exposed because of these disruptions and changing issues. Semiconductor industries are becoming unbalanced, with many companies battling to thrive. Major economic, government and social threats can have detrimental effects on the planet’s sustainability. For example, global temperatures have been steadily rising since people and the manufacturing sector became reliant on fossil fuels. These dangerous fuels power modern-day life’s infrastructure, such as transportation, and heating, and have greatly contributed to the world’s rising CO2 emissions, pollution, and hazardous waste. As a result, all these factors lead to the climate crisis. This article discusses the prevalent key sustainability issues for supply chain resilience, as well as explores possible solutions.

Table of Contents

Reducing the Carbon Footprint

A carbon footprint is a damaging pollution generated by greenhouse gas (GHG) emissions caused directly or indirectly by an organization or people. Carbon emissions are harmful and have an adverse long-term effect on the environment, living things, and people. It causes hazardous acid rain, which increases the consequences of climate change and melts glaciers and polar ice. A country may experience economic losses due to warmer weather in several ways, including decreased agricultural yields, decreased labor productivity, and decreased industrial output. Semiconductors contributed the most to scope 3. Take, for example, staff business excursions, waste disposal, office equipment waste, services, and transport of goods delivery. Recent CNA news in May 2023, the average global temperature has increased by 0.2 degrees Celsius every decade, and it is currently about 1.15 degrees Celsius. Global warming is approaching 1.5 degrees Celsius, owing primarily to rising CO2 emissions. Exceeding that threshold should be regarded as warming, which has a significant climate impact and affects the environment. Improving consumption and production methods, acting as a group, and cooperating with nature are just a few ways to reduce carbon footprint. A business can enhance production processes, employ more energy-efficient equipment, combine shipments, use sea transportation instead of air transportation, and plant trees. Another technology enables the production of photovoltaic solar cells, which may be employed in any semiconductor.

Managing Waste and the Circular Economy

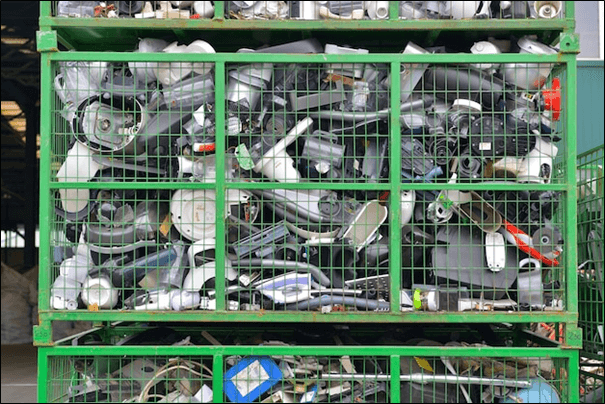

The contemporary economy’s growing volume and complexity of waste pose a severe threat to ecosystems and human health. The UNEP International Environmental Technology Centre (IETC) reported, worldwide, 11.2 billion tons of solid waste are projected to be collected annually. Inadequate waste management causes air pollution, water quality concerns, and soil contamination, ranging from non-existent collection systems to apathetic disposal. The distribution of debris pollutes ecosystems, and harmful compounds from electronic waste or industrial hazardous endanger people and the environment’s health. According to the Environmental Protection Agency (EPA), hazardous waste is referred to as waste that, when disposed of improperly, causes damage to both the environment and people. Heavy metals wasted, dioxin-containing materials, and other liquid toxic materials are examples of hazardous waste. Building a circular economy involves essentially waste management in terms of environmental value. Transitioning to a circular economy requires a collective effort to regulate and replace waste. The fundamentals of the circular economy include resource recovery from non-recyclable, non-hazardous waste, and the creation of renewable energy, or, in other words, little waste and maximum resources. The 3R (reduce, reuse, and recycle) attitude is essential. A circular economy plan confronts significant challenges, including challenging trade-offs. Analyzing the connections between trade and key circular economy policy sectors, investing in product traceability, and information transparency, and engaging in trade in regeneratively grown industries are all critical stages in a larger transition. ASML and Nikon, as real-world examples of waste management and circular economy. Both companies are preparing for ship shortages by extending product lifecycle and recycling or remanufacturing discarded system parts or accessible resources.

Diversifying the Green Partnership

Diversification is one of the strategies that most businesses use to achieve long-term success. Diversification is a risk-mitigation strategy that divides demand across suppliers and separates sales and profits in marketplaces where items appear and rise in demand. When diversification evolves at a quicker rate, the business level might grow into new industrial segments. Diversification includes additional risks such as tax ramifications, investment costs incurred, various regulations for different assets, and restricting growth with the danger of missing out on opportunities. The supply chain’s stability is put at risk by rising finance costs and the possibility of a slump in the economy. The semiconductor industry relies heavily on certain raw materials. As a result, when raw material costs rose, chip prices rose as well. In March 2023, the US government seeks to diversify the semiconductor ecosystem by reducing the dependency on China for industrial product manufacturing and on key chip suppliers located in Taiwan and South Korea, it is looking to cooperate with India This cooperation will evaluate near-term market prospects while also facilitating the long-term strategic development of adjacent semiconductor ecosystems. Diversification does not have to be a binary option. Today, there is a true need for supply chain diversification, however, as always, companies must balance it against other aims, such as cost-efficiency, given the innovation of their market position and larger industry conditions. Simply said, diversifying suppliers and manufacturing partners may help minimize operational expenses, such as cost reduction, payment terms review, and logistical complexity. Supporting a varied range of partners helps to expand prospects and the larger ecosystem. One of the criteria for green partners is vendor pre-qualification processes that are required to fulfill ESG standards and compliance with ISO 9001 (business sustainability), ISO 14001 (environmental sustainability), and ISO 26000 (social responsibility).

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.