Advanced technological solutions have impacted many industries, especially the logistics industry. It is not a simple task to keep up with progress and new technology trends, but the end results will be worth it. The use of these new technologies will help improve new ways of working in the warehouse, thereby increasing the efficiency of workers. The advancement of modern technology has prompted the warehousing industry to use information technology, machinery or equipment, and to use warehousing automation to help simplify complexity and continuously improve its processes. By doing so, numerous benefits can be achieved; Including improving the accuracy of warehouse management, better control the whereabouts of goods, shorten delivery time, and providing customers with the best service. This article discusses some key technologies for efficient logistic operations.

Table of Contents

Warehouse Management System (WMS)

WMS is a software that can be used independently or integrated into an ERP system that supports automation, RFID and even voice or speech recognition. The main purpose of WMS is to ensure that goods and materials pass through the warehouse in the most efficient and cost-effective manner. This system has several functions that can handle those activities and support these movements including receiving, picking, put away, and inventory tracking. It manages the fulfillment operations of the supply chain from the distribution center to the retail shelves, allowing the company to maximize the use of place, labor, and equipment. Furthermore, the software system supports the needs of the whole global supply chain, including distribution, manufacturing, asset-intensive and service operations. By leveraging an industry-leading cloud-based warehouse management system, it can help organizations prepare for the supply chain of the future. WMS Cloud is one of the key features, which helps extend the supply chain, align fulfillment services and inventory management with modern procurement methods, and provide real-time visibility of the whole inventory through the Internet of Things (loT) and browser capabilities.

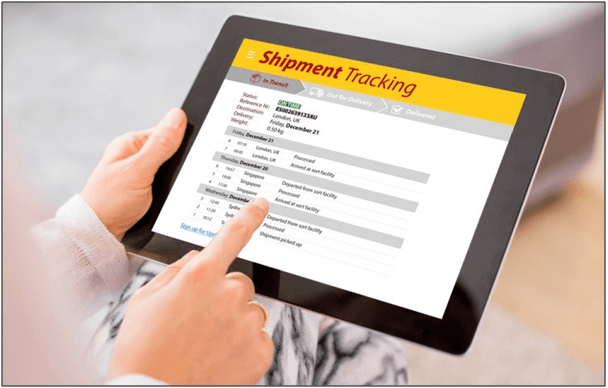

Freight Tracking Technology

The Freight Tracking Technology system is a large and intuitive application that can be used to generate reports, view real-time freight information, receive customized email notifications, and communicate directly with your customer representatives. These include mobile-compatible cloud computing, real-time data, instant messaging, custom reports, and email notifications.The use of cloud computing models helps to increase productivity and reliability, as well as improve the environmental impact. Whether it’s backing up valuable data, easier collaboration across departments (or continents), or instant software deployment, cloud computing enables companies to improve the end consumer experience. Social media can keep consumers informed of logistics news, best practices, regulatory changes, etc. In addition, the business can directly update the customers and other supply chain partners with real-time tracking information, thus improving the visibility down the line.

RFID Technology

RFID is the abbreviation of Radio Frequency Identification. RFID Technology utilizes miniature electronic devices composed of small chips and antennas. The microchips used can accumulate around 2000 bytes of data or information. This device can be used in conjunction with barcodes or magnetic strips; Examples can be found located on the back of ATM cards or credit cards, on product identification labels showcasing a unique identification code of each item. But compared with ordinary magnetic strips or barcodes, RFID devices can be used to obtain more detailed information (including past tracking information). One of the basic advantages of RFID gadgets over other devices is that there is no need to place the RFID device close to the scanner or RFID code reader. In contrast, RFID devices can work within a few feet of the scanner, which is about 20 feet for high-frequency devices.

Automated Picking Technology

The robotic or semi-robotic technology used to implement the automated warehouse picking process can improve the work of manual pickers and help improve the effectiveness and efficiency of the process. There are many options in the field of automatic picking systems for companies to choose from. Hence based on the operations requirements, companies can choose the most suitable and efficient automation tools. These tools can be easily used and seamlessly integrated into existing warehouse processes. In addition, using such automated warehouse picking systems will also help reduce walking time and shorten picking routes. It can be used in a wide range of industries, including e-commerce, manufacturing, retail, transportation, food and beverage, medical equipment, etc.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Celia Ang Ai Loon, DLSM. (2021). “Technologies for Efficiency of Freight Logistics”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/technologies-efficiency-freight-logistics/, accessed 01/12/2021.

Karl Lee Ecijan, DLSM. (2019). “Robotic Process Automation (RPA) for Digital Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/robotic-process-automation-rpa-digital-warehousing/, accessed 01/12/2021.

Marvin Edward, DLSM. (2019). “RFID Technology for Orthopaedic Warehousing and Distribution”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/rfid-technology-orthopaedic-warehousing-distribution/, accessed 01/12/2021.

Muhammad Fadly Bin Mawasi, DLSM. (2021). “Picking Technologies for Smart Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/picking-technologies-for-smart-warehousing/, accessed 01/12/2021.

Ng Song Heng Andy, DLSM. (2020). “Real-Time Location System for Distribution Logistics”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/real-time-location-system-distribution-logistics/, accessed 01/12/2021.

Sures A/L Appalanaidoo, DLSM. (2021). “Smart Technologies for Warehouse Operations”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/smart-technologies-warehouse-operations/, accessed 01/12/2021.

Wong Kam Foo, DLSM. (2020). “Technologies for Improving Logistics Productivity”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/technologies-improving-logistics-productivity/, accessed 01/12/2021.