Transporting dangerous goods is often challenging. Personal injury and property damage may occur if the transportation and storage process are not handled properly. But with the right infrastructure and technology, it can eliminate risk and provide a competitive advantage to the business. Transporting dangerous goods has multiple sets of the process that define safety standards and shipping requirements for up to a thousand types of dangerous goods. The Regulations also provide a means of communicating the nature and extent of the hazards and risks associated with these dangerous goods. Whether it is air, sea, or land transportation, it is very important to understand the classification, packaging requirements, labels, etc. of various dangerous goods.

Table of Contents

Classifying Dangerous Goods

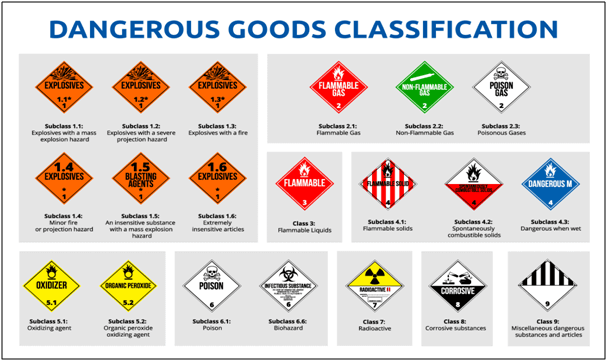

Dangerous goods are classified into nine hazardous categories, containing primary classes and additional sub-classes that describe different types of risk. The definition of hazardous substances (including articles) is broad. However, some pharmaceutical and cosmetic products do not possess the hazardous properties that would bring into the scope of the requirements. Those products are usually packed in small containers that allow at least partial exemptions from the requirements (limited quantities or limited load—refer to main exemption). When transporting materials, the sender must determine whether the material should be classified as dangerous goods. As such, it is very important to understand the classification of dangerous goods.

Assigning Packing Group

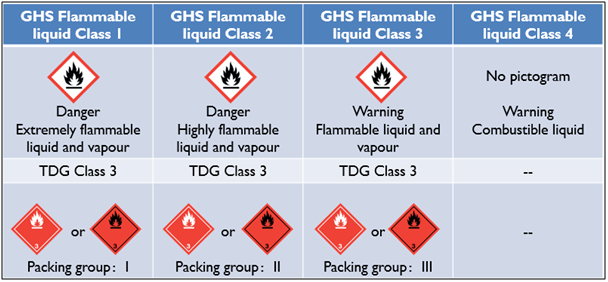

Safety depends on transporting dangerous goods in proper packaging. Choosing the wrong package can cause serious injuries to transport workers, bring harm to the environment, or other catastrophic damage. Appropriate hazmat packaging is based on the product’s most appropriate hazard classification and its physical attributes. For example, it is not allowed to ship corrosive materials in metal packaging because corrosive substances will react violently with the metal and destroy the packaging eventually. Packaging requirements depend on the type, category, and quantity of dangerous goods to be shipped. Typically, packaging must be tested and certified to meet the requirements of dangerous goods transport regulations. Proper packaging also depends on the packaging group of the material.

- Packing group I: substances presenting a high danger and requiring high packaging strength. For example, low flash point class III flammable liquids, class IV class I flammable solids, class V class I oxidants, etc., require class I packaging.

- Packing group II: substances posing a medium risk, and high packaging strength is required. For example, such as Class I explosives, Class II toxic gases, Class IV Class I flammable solids, etc., require Class II packaging.

- Packing group III: substances posing a low risk, with general packaging strength requirements. For example, there are five types of secondary oxidants, four types of secondary flammable solids, and so on.

Labelling Dangerous Goods

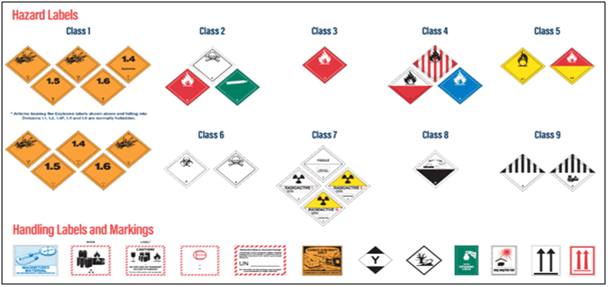

These labels are used to identify the hazard class or classification of dangerous goods and used to designate the hazard class or classification of dangerous goods when carried. Some hazardous materials may have more than one hazardous property. Each hazard must be identified and labelled on the packaging for transport. The potential hazard, specific nature of goods requiring segregation, and stowage conditions, etc. are communicated through marks, labels, placards, and documents. For certain dangerous goods, ICAO technical directives also require the handling of labels and/or other tags to be posted. Hazard labels and other markings must be clearly visible and must not be covered by any tape, text, file bags, or other stickers.

The different types of hazard labels, markings, and handling labels are shown below:

In addition to referring to these markings and labels, shippers and forwarders should check the information on the relevant safety data sheets to confirm the classification and handling of such dangerous goods when shipped.

Receiving and Storing Dangerous Goods

The warehouse should have a special receiving and storage area for dangerous goods. Training of the way to handle these materials should also be provided to the employees. Each duty officer has appropriate personal protective equipment (PPE). The warehouses may also need to segregate hazardous materials based on their classification and packaging groups. Controlling potential ignition sources around flammable materials and processing appropriate safety signs and placards is also crucial. These practices help to reduce the risk of hazards caused by accidental leakage or damage. For example, corrosive liquids can be stored near to flammable gases but not explosives. Learning the rules of storing hazmat materials are crucial in safety and legal aspects. Quarantine sheets should be posted in warehouses with hazardous materials and understood by workers.

Implementing Security Measures

Dangerous goods must be transported by specific regulatory requirements covered by transport regulations. Employees and employers must be aware of these regulatory requirements as they both have a responsibility to store and transport hazardous materials safely. It is also important to observe all necessary safety measures. These may depend on the type and quantity of goods being transported. The introduction and removal of goods from the supply are recorded and can be verified. A similar process applies to passenger transportation, where inventories of vehicles such as planes and trains are monitored. It also includes various measures to maintain security along the transport chain, such as cargo and passenger monitoring. The relevant individual from the management level to cargo handling personnel with be screened and subjected to background checks based on the sensitivity of the relevant shipping method. The data involved in supply chain management has commercial value, so the security of information and telecommunication systems is very important. In addition, a hierarchical access structure to the information must be established based on which information is relevant to whom.

Applying for Approval to Handle Dangerous Goods

Permit controls are implemented in accordance with the Environmental Protection and Management Act (EPMA). The licensing controls prevent unauthorized persons from handling dangerous goods and ensure proper safeguards are taken at all times in the handling of the cargo to prevent and mitigate accidental releases. A license is required for anyone who wishes to import, sell, or export any hazardous substance controlled under the Environmental Protection and Management Act (EPMA) must obtain a Licence. Hazardous Substances Approval (HSTA) is required to ship hazardous substances in quantities exceeding the EPM (HS) regulations. The Transportation Approval Request shall be accompanied by a Transportation Emergency Response Plan (TERP) in SCDF format. For transport in road tankers or tank containers or other bulk containers (capacity equal to or less than 450kg), a true copy of the tanker/tank container inspection certificate issued by an approved third-party inspection agency shall be attached with drawing details to the application.

Conclusion

Dangerous goods transportation is one of the most complex transportation technologies. Due to its specificity and risk, transportation must be precisely controlled, regulated, and handled. It will cause potential hazards to human health, animals, safety, the environment, infrastructure, and/or its vehicles if not properly controlled. It is also important to ensure the preparation, experience, and knowledge of drivers and other actors involved in the transport of dangerous goods. Those who are aware of this will work to maintain a safer distance and fully assess the risk of danger. This can reduce the number of accidents.

References

Bong Ing Chyang. (2022) Major Considerations for Managing Dangerous Goods. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/major-considerations-managing-dangerous-goods/#Identifying_Dangerous_Goods (Accessed: 11 September 2022).

Clarence Tan Wee Lin. (2021) Warehousing Risk Mitigation for Hazardous Chemicals. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/warehousing-risk-mitigation-hazardous-chemicals/. (Accessed: 11 September2022).

Meike Schroder, Gunnar Prause. (2016). Transportation of Dangerous Goods in Green Transport Corridors. Available at: https://sciendo.com/pdf/10.1515/ttj-2016-0029 (Downloaded: 11 September 2022).

Mohammad Ihsan bin Othman. (2022) Critical Factors for Transporting and Storing Dangerous Goods. SIPMM Publications. Available at SIPMM: https://publication.sipmm.edu.sg/critical-factors-transporting-storing-dangerous-goods/. (Accessed: 11 September2022).

TarmoOts. (2000). Transportation and Handling of Dangerous Cargoes in Port Areas. Available at: https://commons.wmu.se/cgi/viewcontent.cgi?article=1242&context=all_dissertations (Downloaded: 11 September2022).