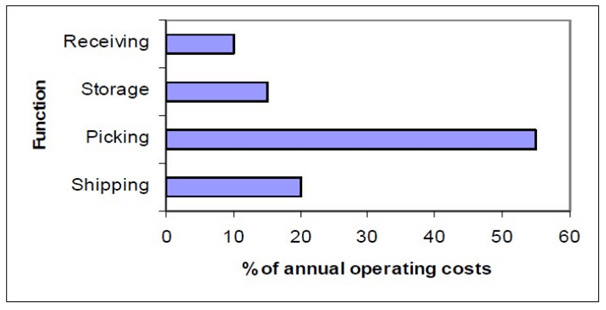

In most distribution centers, order selecting is the most manual, labor-intensive, and high priced operation. It can account for up to 60% of the operation costs. Companies tend to focus on this area first because a variety of enhancement can positively have an impact on their customer’s experience. The distribution center decides on the people picking gadgets from cartons on warehouse cabinets and putting them into boxes for cargo to customers. Picking requires coordination, organization, and thoroughness so that distribution centers easily fill the widest range of orders in the shortest time. The diagram below shows the estimated cost of each function as a percentage of the annual operating cost of running a distribution center.

Ecosystem of Order Picking

Warehouse managers regularly search for strategies to restructure the choosing technique due to the fact it can be time-consuming and costly if no longer executed as effectively to maximize productivity. However, they additionally feel compelled to enhance choosing practices to meet and exceed consumer expectations, as each choosing velocity and accuracy have an effect on customer’s satisfactory.

The diagram below shows the basic ecosystem of order picking.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.