Sustainable procurement is a spending and investment process typically associated with public policy, although it is equally applicable to the private sector. Organizations practicing sustainable procurement meet their needs for goods, services, utilities and works not on a private cost–benefit analysis, but with a view to maximizing net benefits for themselves and the wider world.

In doing so they must incorporate extrinsic cost considerations into decisions alongside the conventional procurement criteria of price and quality, although in practice the sustainable impacts of a potential supplier’s approach are often assessed as a form of quality consideration. These considerations are typically divided thus: environmental, economic and social.

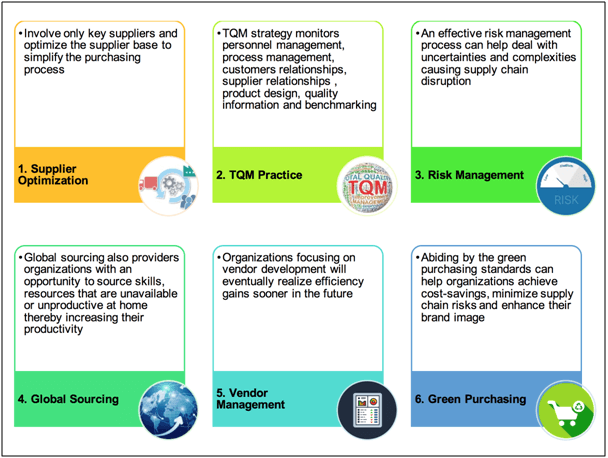

These are the six essential strategies for sustainable procurement.

Table of Contents

Supplier Optimization

The company chooses an optimum mix of vendors who can provide the best prices and terms. This process usually means that the less able suppliers who cannot provide a quality service at the terms and prices required are discarded. This is the most common of the various purchasing strategies.

Sustainable supply base optimization starts with rationalization, a strategic initiative, and supporting processes to initially reduce static or limited-use suppliers; moving beyond simply reducing the number of suppliers and spending more time with fewer suppliers to reduce costs. It then requires critical lean supply chain methods and tools to systematically optimize the supply base size, which is dependent upon supplier performance. Ensuring that supply bases are comprised of capable supply partners and persist at manageable sizes is essential for supply chain operations to effectively manage supplier performance.

Lean supply chain concepts mandate a more intimate partnership with supply partners. When leveraged as part of a Supplier Development Program, supply base optimization can dramatically speed up the implementation and improve the performance of lean supply chain initiative.

Total Quality Management (TQM Practice)

Total Quality Management is the continuous process of minimizing or receiving errors in manufacturing. It is a holistic approach to long-term success that view continuous improvement in all aspects of an organization as a process and not as a short-term goal. The focus of the process is to improve the quality of an organization’s outputs, including goods and services, through continual improvement of internal practices.

Its goal is to completely transform the organization through progressive changes in the attitudes, practices, structures, and systems. TQM efforts typically relies heavily on the previously developed tools and techniques of quality control.

Risk Management

Risk is an event that is capable of impeding procurement from achieving functional and business objectives. There is risk in every supply relationship, without these risks it is difficult to achieve enhanced value. The focus should be on identifying these risks, assessing them effectively and managing them proactively. Therefore, it is good practice for procurement to have a holistic process to risk management. This process should be underpinned by a well-defined risk identification and assessment process, an effective risk strategy and a managed risk register. All risks and issues should have clear mitigating actions, appropriate owners and a review date.

For example, analysis of all costs and supply disruption; Identity opportunity – future trends in the supply market, explore the new business opportunity, search for innovation on circular economy concept product. The risk assessment process is for controlling and to mitigate the risk, act to reduce the risk by developing corrective and improvement action plan, bind it into governance and procurement policy.

These processes are extremely important to the organization in a constantly changing business environment, the procurement team is responsible for continuously identifying, assessing the risk and opportunity related to company competitive advantages.

Global Sourcing

Large multinational companies see the world as one large market and source from many vendors, regardless of their country of origin. It aims to exploit global efficiencies such as lower cost skilled labor, cheaper raw materials and other economic factors like tax breaks and low trade tariffs. Examples are call centers in the Philippines, clothing and shoes manufactured in China and Thailand. Companies that have implemented global sourcing have leapt ahead of the pack reducing the cost of goods, accelerating the speed to market and improving the quality on a consistent basis.

The below diagram is an example of Global Sourcing Framework.

Vendor Development

Some companies believe that they are working hand-in-hand with their vendors. They therefore spend some time in developing processes that assist these vendors. There may also be the situation where a company is dependent upon just one supplier for their products. If this supplier is unable to perform to the required standards, the purchaser may assist the vendor in improving their service or implement processes to improve their procurement cycle.

Green Purchasing

This is one of the more common purchasing strategies for governments and local organizations. This strategy champions the need for recycling and purchasing products that have a negative impact to the environment.

It is a combination of being “green” and being socially and ethically responsible. Organizations implementing sustainable procurement should aim to minimize damages to the environment while delivering economically sound solutions. Some measures adopted by such organizations include the use of sustainable raw materials in their supply chain, engaging minority, women and small businesses, as well as reducing particulate matter and greenhouse gases emission.

Conclusion

To procure in a sustainable way involves looking beyond short-term needs and considering the longer-term impacts of each purchase. Sustainable procurement is used to ensure that purchasing reflects broader goals linked to resource efficiency, climate change, social responsibility and economic resilience.

Sustainable procurement involves a higher degree of collaboration and engagement between all parties in a supply chain. Many businesses have adopted a broad interpretation of sustainable procurement and have developed tools and techniques to support this engagement and collaboration.

References

Billy Jane Baliwagen. (2017) “So what is global sourcing” Retrieved from https://www.purchasing-procurement-center.com/what-is-global-sourcing.html, accessed 07/09/2019

Billy Jane Baliwagen. (2017) “The 6 core purchasing strategies” Retrieved from https://www.purchasing-procurement-center.com/purchasing-strategies.html, accessed 08/09/2019

Daniel Usifoh. (2019). “How to manage risk in procurement”. Retrieved from: https://www.gatewayprocurement.co.uk/insights/how-to-manage-risk-in-procurement/, accessed 07/09/2019

Khoo Chai Luan. (2018). “Overcoming Key Challenges of Sustainable Procurement Practices”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/overcoming-key-challenges-sustainable-procurement-practices/, accessed 07/09/2019

Mickie Foong. (2019). “Key Considerations for Sustainable Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-sustainable-procurement/, accessed 07/09/2019

Shooger. (2018). “Total quality management and purchasing”. Retrieved from: https://www.slideshare.net/Shooger/total-quality-management-and-purchasing, accessed 07/09/2019