In cold chain transportation, the stakes are high. Fines for regulatory non-compliance, losses from spoiled perishable merchandise or worst, sick end-consumers can be the result of uncontrolled temperatures. The food and drink transportation industry is going through a revolution, influenced by modern consumer needs, new regulatory pressures and innovations in technology. In order to stay competitive and compliant, manufacturers need to act promptly or risk falling behind.

Table of Contents

Understanding Telematics Technology

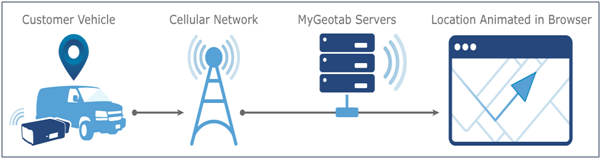

Basically, it is an amalgamation of two technologies, namely telecommunications and informatics. It is the technology that is increasingly used in the automotive segment for vehicle tracking and monitoring and also to send, receive and store information. It is an aftermarket solutions cater to the automotive industry. It communicates and controls remote objects. Usage of telematics in fleets involve monitoring the location through satellite GPS, movement as well as status in building a comprehensive and accurate view of their networks data.

It provides intelligent fuel location, local business search/recommendation, en route news, weather and traffic updates while providing in-vehicle entertainment as well as real-time data communications. It gathers the speed and position of cars to alleviate traffic jams, enables location reporting or sharing. It provides wireless safety and hazard alerts, emergency or roadside assistance request for freight trailer and container tracking.

In-vehicle video systems provide alerts for anti-collision, lane deviation and other safety warnings. It can also be used to automatically adjust the speed of the vehicle based on the official speed limit.Electronic signatures ensures the safe delivery of goods while keeping logistics’ operators informed about shipping schedules in real-time. It allows warehousing and logistics to correctly receive and deliver goods and to eliminate blind spots in the business.

Investigation and Assessment

The main responsibility of the main distributor or forwarder is to identify weaknesses in existing practices to safeguard quality of product. Best practice for customer care is to set up investigation team to enforce, implement and conduct supply chain security and quality investigations. With telematics, stages of a cold chain can include data and accurate locations where products are transformed, change hands through transport, docks hangers and internal checkpoints and stops while collecting evidence to link each stage of a product’s journey, from its origin. Such investigations and findings can have an impact on the reputation and the financial status of the companies involved. An important aspect in supply chain is traceability which is the passing of information from one stage to the next.

Unpredictable nature of cold chain research means that it is not always possible to anticipate and forecast risk as it is a natural part of the supply chain ecosystem but getting early insight and improving past trends. With IoT devices, use of sensors to measure aspects of the chain such as location, humidity, temperature, movement, light levels, handling, speed of movement and other environmental factors. It come in many form such as RFID chips, smart devices and mobile sensors.

Risk management is another area where supply chain transparency is essential and assess weak link that would jeopardize product integrity.

Quality Securities

Alerts will be given in the form of real-time text messages or e-mails. It is programmed for cargo monitoring such as difference of ambient and inside temperature to the set point, failure to turn on the refrigeration unit or ULD/reefer door opened, unauthorized handling of temperature active equipment. It also caters to the safety of drivers and equipment such as doors openings outside authorized areas, unauthorized motion detection and speed alerts.

- Simplify compliance

Third-party temperature measurement will be logged in the cloud and allows easy access to online reports for as long as needed.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.