While the Covid-19 pandemic is reminding us every life-being is interconnected and interdependent, the threat of global climate change is continuing. Some of the not-for-profit sectors, as essential service providers are still running the services during the Circuit Breaker period. Human activities, such as switching on the air conditioners in the office and ordering food deliveries with disposable packaging, have contributed carbon dioxide emissions and driving up temperatures.

According to the IPCC report, “Global sea-level will rise around 10cm higher for a global temperature 2˚C increaseby the year 2100. The increase could cause up to 10 million fewer people exposed to the risks of rising seas.” As such, the sector needs to switch to a Circular Procurement mind-set.

https://www.shutterstock.com/image-photo/city-showing-effect-climate-change-88550854

Table of Contents

Importance of Circular Procurement

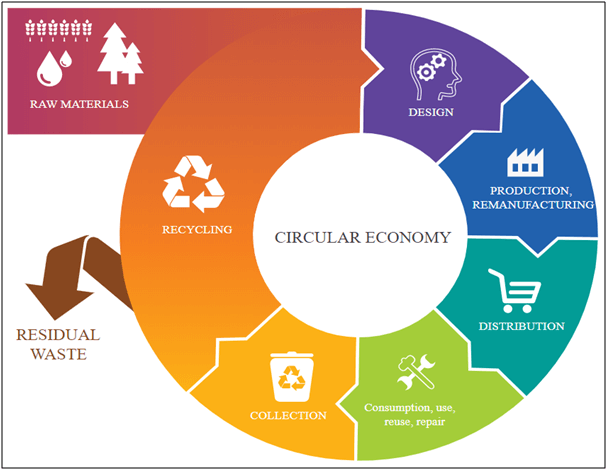

Circular procurement is both an idea and system focused on maximising the utilisation of the resources and minimising waste. The closed-loop approach is to consider the requirements of the products/services and the consequences of the products/services after the end of its life. It is also considering the hidden costs and to identify the risks and impacts. It delivers multiple benefits to the organisation:

- To allow the purchasers to focus on need fulfilment and consider whole life costs with potential savings.

- To provide a framework for a more holistic consideration of environmental impacts and waste creation across the entire lifecycles of goods and services.

- To turn the not-in-use products into profit with lower costs than making a new product from scratch instead of throwing them away at the end of their lifecycle.

https://www.europarl.europa.eu/news/en/headlines/economy/20151201STO05603/circular-economy-definition-importance-and-benefits

In this article, we will be focusing on discussing the challenges and possible enablers of switching the procurement model to Circular Procurement for the not-for-profit sector. We can classify the challenges into seven categories: Economic and financial viability, Product characteristics, Standards and Regulations, Supply chain management, Technology, Users’ behaviour, and cultural and internal process.

Economic and Financial Viability Challenges and Enablers

Not-for-profit organisations cannot succeed without a strong core of funding which comes from donations, grants, fundraising as well as volunteers. Hence, every single cent counts for each expense. To switch the procurement model into Circular Procurement, it will need high upfront, and long term investments, especially when it comes to the management and planning processes due to the complex practices.

Most investors are still having a linear economy mindset. Hence, they will be focusing on short term value creation and selecting the raw materials which prices are relatively low.

One of the enablers to short term value creation is to emphasise the importance of Total Cost of Ownership. Whole life costing and new techniques incorporating environmental, social and governance dimensions shall be taken into considerations. Whole life costing is to access the total cost of a product or service over its lifetime, from purchasing, operating, maintaining and managing the end of its lifecycle.

Instead of purchasing and owning the products, we can look for a product-service system, e.g. leasing, pay-per-service, sharing, etc. For instance, the social workers and volunteers have to organise home-visit to the patients/care recipients timely. Some of the volunteers who own a car can offer car-sharing to others who are heading to the same location to minimise the carbon footprint generated per ride. Otherwise, they can also share a taxi to the same area.

Product Characteristics Challenges and Enablers

In some cases, product characteristics may affect the buying decision of an organisation. Managing complex products throughout the whole lifecycle is always challenging, and hence organisation will not change the way of handling if unnecessary. Similar to the product mass customisation, it will push towards more personalised products which increase the difficulty to recover the materials in a standardised manner. For instance, some of the medical consumables used in Charity and Medical purpose cannot be reusable due to hygiene purpose.

People are hesitant to take the first step. As a procurement professional, we shall always embrace ourselves into new knowledge, such as circular knowledge. Once we have sufficient knowledge of the product as well as the process, we can always put the circular ideas into practice and share the information in the organisation. Many of the innovative products we have today were made a reality with time, patience and efforts. We shall always start with relatable things and keep it simple. Once we grab the successful example, we can lead by feasible example and grow big. The keys are communication, coordination and integration.

By using circular procurement concept, there is a not-for-profit organisation in Taiwan has successfully manufactured various textile products with the recycled Polyethylene Terephthalate (“PET”) bottles. A 70 x 90 inches eco-blanket will require 76 PET bottles as its raw materials.

Standards and Regulation Challenges and Enablers

The operations of the not-for-profit organisation will have to be bound by the country’s standards and regulations. Most of the times, labour taxation rate is higher than raw materials. There is no alignment between existing taxation and incentives and the adoption of Circular Procurement paradigm. Also, as the Circular Procurement concept is not shared worldwide, the regulatory framework is not consistently in place. Any organisation to adopt the idea does not have any reference and may not know where to start. It can become very costly to have a trial and error without uniform regulations.

For standards and regulations, we need government supports to facilitate and promote circular initiatives. For instance, the government can always provide an incentive for organisation staff to enhance their skills and innovation by taking the relevant course. Development of standards and assurance schemes is crucial to standardise the individual process. However, this is not lie in the power of a single organisation.

Supply Chain Management Challenges and Enablers

Economic scale cannot be achieved in reverse logistics as there is the uncertainty of the return flow, such as the quantity, mix, quality, time and place of returns of products. Moreover, the transportation costs will be increased by sending the used items to the vendors and indirectly cause an impact on the environment. There is a lack of available and suitable supply chain partners who can recognise the concept and cause an absence of coherent vision to achieve circular procurement goals. Even if there is a strategic partner, a lack of trust in partners will cause a breakdown in communication and information-sharing, and there is no alignment about the shared risks and the shared values of the initiatives.

We can establish a strong partnership among different supply chain organisation to enhance information sharing and mitigate other supply chain challenges. We can also improve the product traceability by equipping suitable tracing tools to enhance the effectiveness in planning and executing the product returning process.

Technology Challenges and Enablers

Technology plays a vital part to adopt circular procurement. From the research by Lloyds Bank, not-for-profit organisations that have fully equipped with digital technologies are 28% more likely to grow their funding. For instance, to reduce paper waste created due to document printing for verification, the organisation will have to convert the existing manual operation into the e-procurement system. However, this will require technical and technological know-how and expertise. There are not many qualified professionals with technical or information technology knowledge in the market.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Bet, B. et al. (2018), “Barriers and Best Practices for the Circular Economy”. Retrieved from https://repub.eur.nl/pub/105039/Barriers-and-Best-Practices-for-the-Circular-Economy.pdf, accessed 12/06/2020.

Bianchini, A. et al. (2019), “Overcoming the Main Barriers of Circular Economy Implementation through a New Visualization Tool for Circular Business Models”. Retrieved from https://www.mdpi.com/2071-1050/11/23/6614, accessed 12/06/2020.

Bressanelli, G. et al. (2019), “Challenges in Supply Chain Redesign for the Circular Economy: a literature review and a multiple case study”. Retrieved from https://www.tandfonline.com/doi/full/10.1080/00207543.2018.1542176, accessed 12/06/2020.

Hart, J. et al. (2018), “Barriers and drivers in a circular economy: the case of the built environment”. Retrieved from https://www.napier.ac.uk/~/media/worktribe/output-1638316/barriers-and-drivers-in-a-circular-economy-the-case-of-the-built-environment.pdf, accessed 12/06/2020.

Lai Wan Voon, ADPSM. (2020), “Three Critical Enablers Circular Supply Chain”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/three-critical-enablers-circular-supply-chain/, accessed 12/06/2020.

Mickie Foong Mee Keat, PDPM. (2019), “Key Considerations for Sustainable Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-sustainable-procurement/, accessed 12/06/2020.

You Matter, (2020), “Circular Economy: Definition, Principles, Benefits And Barriers”. Retrieved from https://youmatter.world/en/definition/definitions-circular-economy-meaning-definition-benefits-barriers/#:~:text=%E2%80%9CLooking%20beyond%20the%20current%20take,waste%20out%20of%20the%20system., accessed 12/06/2020.

Zaiton Binte Abu Bakar, ADPSM. (2019), “Essential Strategies for Public Procurement Practices”. Retrieved from https://publication.sipmm.edu.sg/essential-strategies-public-procurement-practices/, accessed 12/06/2020.