Electric vehicles (EVs) have quickly gained popularity as a vital response to environmental issues. These have exposed complicated ranges of logistics issues relating to their battery ecology. This thorough investigation digs into the key concerns supporting the efficient incorporation of EV batteries into the contemporary transportation landscape. This article navigates the complex terrain of EV battery logistics, covering everything from complex supply chain vulnerabilities. These issues include raw material sourcing, battery transportation intricacies, recycling challenges, and grid integration. There are also the regulatory impacts, safety considerations, and emerging technology disruptions. By examining and addressing these concerns, stakeholders may establish a sustainable, effective, and imaginative future for electric mobility while paving a cleaner path for the environment.

Table of Contents

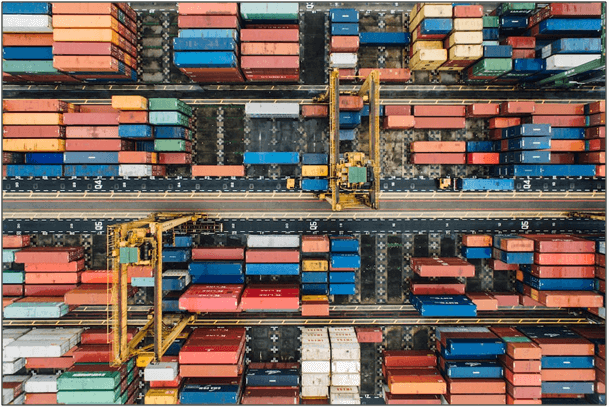

Supply Chain Vulnerabilities

The development of the electric vehicle (EV) sector depends on a complex supply chain that is susceptible to failure. Geopolitical tensions, industry issues, and market volatility can disrupt the smooth flow of batteries for electric vehicles. Diversifying sourcing channels, forming alliances, and localizing production facilities are all strategies for improving supply chain resilience. It is critical to reduce interruptions by implementing risk management procedures and proactive monitoring. It is crucial to comprehend and alleviate supply chain risks, especially with the increasing role of electric vehicles in promoting sustainable mobility. Stakeholders can ensure consistent access to battery components, supporting the growth of the EV market. Overcoming the challenges posed by global dynamics requires strengthening supply chain networks and adopting agile techniques.

Raw Material Sourcing

It is important to consider the responsible sourcing of critical raw materials, which presents a significant challenge. EV battery production raises ethical concerns about mining practices and environmental damage caused by mining lithium, cobalt, nickel, and rare earths. It is crucial to prioritize sustainable mining practices to ensure a cleaner future. Moreover, their availability is vulnerable to geopolitical tensions and market instability. A diversified strategy is needed to address these raw material sourcing issues. Responsible sourcing practices, supply chain transparency and adherence to ethical standards are critical. Researching alternative materials, investing in sustainable mining practices, and developing recycling technologies are crucial steps to reduce dependence on scarce resources. These concerns must be addressed to secure a sustainable and ethical supply chain for the EV sector.

Battery Transportation Complexity

The intricacies of EV battery transportation are a significant undertaking in pursuit of sustainable mobility. Lithium-ion batteries contain a high energy density and present a substantial challenge due to the risk of thermal runaway. Implementing specific security protocols and regulatory guidelines is essential for ensuring safe transportation. Thus, the collaboration among manufacturers, shippers, and regulators is crucial for developing safe transportation processes. Innovative packaging options that can withstand shock, vibration, and temperature variations are essential for preserving battery integrity during transportation. Stakeholders can ensure the secure delivery of electric car batteries by effectively addressing the challenges of battery transportation. These enhance customer trust and facilitate the smooth evolution of the e-mobility market, with the safety of all stakeholders at the forefront.

Recycling and End-of-Life Logistics

Managing the end-of-life phase of batteries is becoming a critical sustainability challenge with the increasing use of electric vehicles. Recycling is essential in minimizing negative environmental consequences and increasing resource recovery. It is crucial for building an efficient recycling infrastructure that incorporates standardized dismantling techniques and promotes circular economy principles. Manufacturers, recyclers, governments, and consumers must collaborate to establish efficient networks for collection and recycling. Additionally, extending the life of spent batteries and minimizing waste can be achieved by exploring secondary applications, such as energy storage systems. The electric vehicle industry can proactively address environmental concerns and reduce dependence on raw materials. Furthermore, handling recycling and end-of-life logistics can contribute to a more circular and ethical approach to battery technology.

Grid Integration and Energy Storage

Batteries for electric vehicles have the potential to revolutionize not only transportation but also harmonize with power grids. The ability to efficiently utilize renewable energy sources can be enabled by seamlessly integrating EV batteries with the power grid. This integration can also increase energy storage capacity and enhance grid stability. However, for this integration to succeed, the energy and transportation sectors must collaborate effectively. Grid integration works best when regulations align with advanced smart grid technologies and innovative energy management systems. Policymakers and stakeholders need to comprehend how supply, demand, and regulatory frameworks interact to realize the synergistic benefits of grid integration. Through this approach, energy storage can provide a reliable and resilient electricity future as electric vehicles become a distributed energy source.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.