Technology is making the warehouse process more efficient by augmenting the work of humans or automating tedious and manual tasks. Warehousing is a vital part of the logistic system and is essential for any industry with physical goods movement within the supply chain. Advanced digital technology such as warehouse management systems (WMS) and Internet of Things (IoT) Technology lead the warehouse industry to improve the performance of logistical operations at the warehouse constantly. The technology can be adopted in the warehouse to assist the activity and improve the workflow of the warehouse. Warehouse automation help to reduce human error, and labour cost, improving safety and increasing productivity and accuracy. This article discusses various technologies that can enhance efficient warehousing and provide economic benefits to both businesses and customers.

Table of Contents

Internet of Things (IoT) Technology

IoT is a network to combine digital machines, computers, software, and system to allow devices to communicate at the same frequency to complete instruction. IoT enables the automation of processes in the warehouse to reduce labor costs, moreover, reduce waste, and improves delivery management. With IoT companies can review the status of assets, process flow, and even real-time with a click on a mobile phone or computer. Internet things have become essential for business owners since it provides real-time data and information and delivers insights. The Important of IoT for integrated logistics Is to predict, manage and improve the process of logistics. This technology helps warehouses utilize the space in the facilities to distribute and organize goods efficiently.

Warehouse Management System (WMS)

A Warehouse management system (WMS) is essential software to cover the entire logistics daily operation. Its software is designed to trace the movement of time when it receives in and supplies out from inventory. WMS captures the real-time inventory information to provide visibility of inventory information and manage fulfillment for the entire warehouse operation. This technology can improve the receiving process, reduce the time of order fulfillment, reduce waste of motion, and eliminate waste of labor costs. It also oversees warehouse activities and allows businesses to get a competitive advantage. It helps to increase warehouse productivity, increase reliability, improve inventory accuracy, and stock reliability, and improve the performance of logistics operations at the warehouse. By using the technology with WMS, the WMS can collect accurate time information for the user and allow the users to assign a location in the warehouse by removing it.

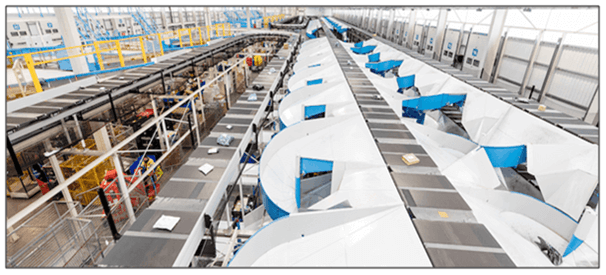

Automated Storage and Retrieval System (AS/RS)

ASRS system provides highly dense storage and can entirely save floor space occupied by shelving. An automated system is the most effective solution when it comes to increasing storage capacity vertically. The system is programmed to execute repetitive tasks with high precision. Handling products with an ASRS significantly reduces damages usually caused by human error in handling products with a forklift or other equipment. This system increased accuracy in handling product data. Practically all Automated Storage Retrieval Systems controlled by a warehouse control system (WCS) or warehouse management system (WMS) can automatically transfer product tracking data. ASRS effectively eliminates all the risks and helps to reduce the level of actability and security, thus reducing the number of goods that must be scrapped due to damage.

Automated Guided Vehicles (AGVs)

Vehicles are controlled via computer and carry a load of products autonomously within the warehouse. AGVs used sensors and lasers to scan their surroundings, allowing them to navigate around obstacles without human intervention. The technology used in warehouses reduces the need for humans to operate the vehicle system. The primary benefit is increased warehouse productivity and reduced staffing costs, including hiring, training, and managing staff. Robots tend to be more accurate, and it has a lower error rate when performing repetitive tasks such as moving items from one place to another within a warehouse activity. Automated vehicles perform repetitive tasks without getting tired or needing breaks, allowing them to work 24/7 without requiring additional human sources.

Autonomous Mobile Robots (AMRs)

AMR are robots that can move through their environment without any human intervention or on a pre-determined route. This technology is often the backbone of cheap drop-shipping industries and functions around the clock to help warehouses and manufacturers get their products to customers. Its help to eliminate repetitive mundane task from workers, allowing them to work at a station more conducive to workers’ health and productivity. Autonomous robots can decide on their own based on a set of parameters it takes from their environment. Mobile robots allow an organization to free up laborers to perform more value-added activities within warehouse operations. AMRs are helping to reduce the load of working during peak production without the burden of hiring more workers for warehouses.

Radio-Frequency Identification (RFID)

Radiofrequency can track and trace assets, products, and human resources and follow the manufacturing process. The automation made possible by RIFD technology helps to collect and upload information electronically. RFID identification efficiently captures real-time data in all product life cycle stages. This technology reduces total order cycle time and errors made in deliveries of customer orders. RFID tags also can minimize inventory inaccuracies. The scanner warehouse can immediately detect how many products there are, rather than having to count boxes by hand. The efficiency of RFID technology controls warehouse production to keep production costs, leading to higher profit margins. Additionally, quality products can give a competitive advantage, leading to improve sales due to customer satisfaction.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.