Key technology for a smart warehouse is rapidly advancing. Warehouses must be equipped with the technology that enables them to meet the demands of manufacturing and customers. For greater production, efficiency, and accuracy, a sensible warehouse has to be automated. Technologies are used to give flexibility, capability to the personnel and their operations. Several technologies should be included in the smart warehouse such as Internet of things (IoT)technology, blockchain technology, robotics and automation, artificial intelligence (AI) technology, automated guided vehicle (AGV), drone RFID technology, mobile and wearable technology, and automatic storage retrieval system (ASRS). This article discusses smart technologies that will improve the warehouse operations for organizations.

Table of Contents

Internet of Things (IoT) Technology

IoT is usually referred to as technology in the warehouse business for operation functions by three levels such hardware infrastructure, data interchange processing, and software layer. The smart warehouse may use the IoT technology to track and manage commodities in real-time. Real-time knowledge regarding a shipment’s physical state is of significant value, as is optimization potential. Companies may use IoT systems to monitor items in real-time, ensuring arrive when and where they should. Data processing and IoT computing capacity have been relocated closer to the network edges. With cloud-based services accessible, it is vital to acquire, explore, and act on data. Human inventory activities can be eliminated by integrating IoT and robotic process automation (RPA).

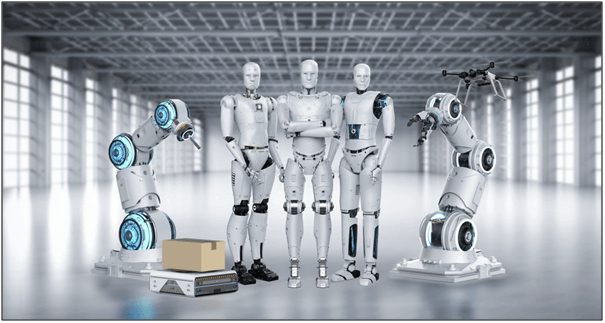

Robotics and Automation

Robotics is a branch of technology that deals with the design, building, operation, and use of robots that may be programmed to perform specified tasks. Humans can be replaced by advanced robots that safely execute monotonous activities. It’s is also be used on behalf of someone in a potentially harmful situation. Advantage automation operations systems require minimal to no human intervention. The first step toward warehouse automation is to invest in these two technologies. The warehouse industry recognizes operations are redundant, process-oriented, and error-prone. Some repetitive manual operations can be automated for more consistent, accurate, and effective warehouse operations. Such activities include receiving, picking and storage.

Automated Guided Vehicle (AGV)

Material handling equipment for autonomous driving is known as Automated Guided Vehicle (AGV). The machinery can operate 24/7, i.e. twenty-four hours a day and seven days a week. They can prepare the materials for operators before they start work and thus increase factory production. Using both vehicles and semi-automatic warehouse equipment, the operation can tackle a wide range of warehouse chores using unique technology. From single robots to automated robots, this will lead engineering to offer software and system configurations. This will thus increase productivity by replacing regular chores and procedures with autonomous guided vehicles (AGVs). When the user is approaching, AGV will slow down and the electromechanical bumpers are turned off in the event of a collision.

Mobile and Wearable Technology

Mobile and wearable solutions are emerging trends, new degrees of complexity are being offered to assist warehouses in rebuilding operations efficiency and productivity. Technology makes use of smart sensors that are controlled by a warehouse management system will enable access to large amounts of data while also speeding up warehouse operations. Technologies are now fully integrated into the quality warehousing process, allowing real-time information to flow across the organization and supply chain. Mobile wearable devices improve flexibility and security when doing repeated jobs. Keep user hands as free as possible allow the system to focus on actual operation handling. Mobile and wearable sensors can also detect potential hazards in specific ways or places and recommend preventative safety measures.

Automatic Storage and Retrieval System (ASRS)

Automated storage and retrieval systems have been around for a long time in warehouse operation to improve accuracy. A company can use historical data trends to simulate projected forecasts with optimal inventory levels and SKU rate classifications. This data will accurately indicate the size, the capacity of ASRS in the company and will have a positive impact on the entire order fulfilments process. User by using the right ASRS model in operations of picking from shelves, hoppers, and robotics will lead to maximizing return on investment by saving money and time. In today’s ASRS are growing technology while maintaining all of their initial benefit’s lower costs of restrictions, modular capabilities, and better accuracy.

Drone RFID Technology

The smart way of utilizing drones with RFID technology for warehouse inventory management enables businesses to employ smaller and safer drones than previously to find products in large facilities. RFID tags are gradually replacing warehouse barcodes. RFID tags used in inventory management systems assist in automating and enhancing inventory management systems. From pet microchips to implanted chips that are optional for corporate personnel, little tags that function with the reader’s radio frequency for a brief period will be found everywhere. Drone hacking is quite convenient. RFID tags, unlike barcodes, do not require line-of-sight reading the information stored in tags is more extensive and easier to alter. Drones are fitted for safety reasons, with smaller relays utilized in confined areas and plastic parts that are not prone to harm.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Alan@ Muralidhran, GDLSCM. (2021). “Smart Technologies for Integrated Logistics Operations”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/smart-technologies-for-integrated-logistics-operations/,accessed 3/12/2021.

Nillian Low, ADPSM. (2019).“Integrating AI with IoT for an Effective Supply Chain”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/integrating-ai-iot-effective-supply-chain/, accessed 3/12/2021.

Razit Bin Mydin, DLSM. (2021). “Key Considerations for Establishing a Smart Warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-establishing-smart-warehouse, accessed 3/12/2021.

Sures Appalanaidoo, DLSM. (2021).“Smart Technologies for Warehouse Operations”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/smart-technologies-warehouse-operations/, accessed3/12/2021.

Vijay Haresh Melwani, GDPSCM. (2021).“Digital Technologies for Building Supply Chain Resilience”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technologies-building-supply-chain-resilience/,accessed 3/12/2021.

Winnie Soh Pin Pin, DPSM. (2019). “5 Essential Technologies for Inventory Control in a Warehouse Contract”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-essential-technologies-inventory-control-warehouse-contract/,accessed 3/12/2021.