Building Information Modelling (BIM) is identified by many countries including Singapore as a key technology to improve productivity and increase the level of integration across various disciplines in the entire construction value chain. It is the main enabler for achieving Integrated Digital Delivery (IDD), one of the key thrusts in the Construction Industry Transformation Map (ITM) launched during the Singapore Construction and Productivity Week in October 2017.

So what exactly is BIM and its benefits which make many believe to be the main technology to transform the construction industry? What are the critical factors for the successful implementation of this technology?

Table of Contents

BIM Technology

Before BIM became common, designing buildings and other structures were dependent on 2D drawings. Various departments would have to pass these drawings back and forth between each other. A BIM tool allows users to generate and manage digital representations of characteristics and functions of building structures. In addition, BIM software provides information such as spatial relationships, light analysis, and geographic information.

This process can also break down the actual building parts to piece together how they fit into one structure. These elements can include walls, columns, windows, door, stairs, and more. This data can be extracted, networked to, or exchanged to facilitate decision-making regarding the specific building or structure the user is designing. For example, a user can manipulate this information to understand these elements’ behavior before building construction begins.

There is a common misconception that BIM is merely a technology which creates a 3D design model. It is actually a process for creating and managing all the information about a project, with the end product known as Building Information Model, which consists of digital information of every aspect of the physical project.

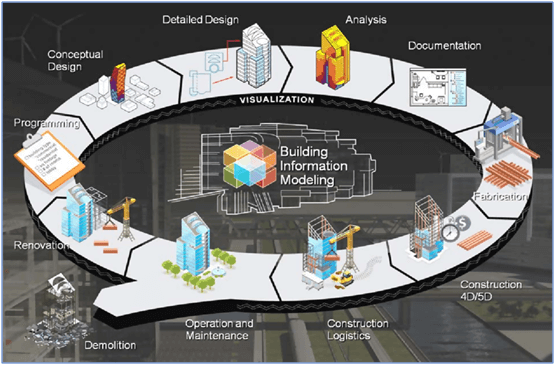

BIM can be viewed as a virtual process that encompasses all aspects, disciplines, and systems of a facility within a single, virtual model, allowing all design team members (owners, architects, engineers, contractors, subcontractors, and suppliers) to collaborate more accurately and efficiently than using traditional processes. As the model is being created, team members are constantly refining and adjusting their portions according to project specifications and design changes to ensure the model is as accurate as possible before the project physically breaks ground. When construction is finished, the BIM model became an invaluable resource for facility manager who could easily extract information about the model

Applications of BIM Technology

1. Visualization

3D renderings can be easily generated in a house with little additional effort.

2. Fabrication/shop drawings

It is easy to generate shop drawings for various building systems. For example, the sheet metal ductwork shop drawings can be quickly produced once the model is complete.

3. Code reviews

Fire departments and other officials may use these models for their review of building projects.

4. Cost estimating

BIM software has built-in cost estimating features. Material quantities are automatically extracted and updated when any changes are made in the model.

5. Construction sequencing

A building information model can be effectively used to coordinate material ordering, fabrication, and delivery schedules for all building components.

6. Conflict, interference, and collision detection

Because building information models are created to scale in 3D space, all major systems can be instantly and automatically checked for interferences. For example, this process can verify that piping does not intersect with steel beams, ducts, or walls.

7. Forensic analysis

A building information model can be easily adapted to graphically illustrate potential failures, leaks, evacuation plans, and so forth.

8. Facilities management

Facilities management departments can use it for renovations, space planning, and maintenance operations.

The various applications of a building information model can be depicted in the diagram below (MEP refers to mechanical, electrical, and plumbing).

The BIM Technology for Construction Value Chain

1. Create quickly

Before BIM software, the building design process involved a lot of manual drawings. These solutions enable designers to draft up a BIM model far quicker than by hand. Digital models also include more information than what is in a drawing set. Ultimately, by facilitating a quicker design process, BIM software saves firms money and labor.

2. Design anywhere

The majority of BIM solutions are cloud-based, which means that one can have access to the project’s details from any device. Multiple project members can sign on from any location as well.

3. Avoid clashes

BIM can detect clashing elements, such as electrical conduit or ductwork that run into a beam. Repairing the damage from clashes can be very costly. BIM tools have the ability to identify potential issues before they happen.

4. Capture reality

One of the foremost advantages of this software is BIM’s ability to accurately capture reality. BIM solutions can integrate with tools that offer to map and provide precise images of the earth. Users then have the option to include aerial imagery and digital elevation with the models of their buildings. They can even include laser scans of existing site infrastructure.

5. Reduce errors

As BIM software takes away manual design, it also takes away a significant amount of human error. These tools help identify problems early on in the design and building processes.

6. Improve collaboration across the organization

Sharing digital information modeling for buildings is far easier than passing drawing sets back and forth between colleagues. The cloud-based model of many BIM solutions also means that colleagues working on different parts of the design and building process can access BIM models anywhere, at any time. As many colleagues as needed can review and mark up the model before the building is erected.

7. Simulate and visualize elements of the building

BIM software has the capability to visualize how certain elements can impact the building, such as sunlight during different seasons or the structure’s energy performance. These solutions apply rules based on physics to provide guidance for engineers and other team members involved in building the structure.

8. Sequence the steps of the building process

Constructing a building is an incredibly detailed process. Each part of this progression is a sequence of steps,

materials, and building crews. BIM software can animate this entire process, facilitate all of these steps, and deliver a path to the end result.

9. Give a perfect presentation

It is important clients get a preview of the building being designed. BIM software enables communication of the project scope, steps, and outcome. And as BIM can render images in 3D, clients would be given the most realistic view of the building possible.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Shivakumar Sundar, DLSM. (2018). “Overcoming Challenges in Implementing Supply Chain for the Construction Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/overcoming-challenges-implementing-supply-chain-construction-industry, accessed on 01/03/2019.

Rae Choong Bee Ling, DPSM. (2018). “Impact of Digital Technology for Project Delivery and Execution”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/impact-digital-technology-project-delivery-execution, accessed on 25/03/2019.

G2 Crowd. (2019). “Learn More About Building Design and Building Information Modeling (BIM) Software”. Retrieved from https://www.g2crowd.com/categories/building-design-and-building-information-modeling-bim#learn-more, accessed on 25/03/2019.

Engineering.com. (2016). “BIM 101: What is Building Information Modeling?”. Retrieved from https://www.engineering.com/BIM/ArticleID/11436/BIM-101-What-is-Building-Information-Modeling.aspx, accessed on 21/03/2019.

Salman Azhar. (2011). “Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry”. Retrieved from https://ascelibrary.org/doi/full/10.1061/%28ASCE%29LM.1943-5630.0000127, accessed on 22/03/2019.

Building and Construction Authority. (2018). “What is Integrated Digital Delivery (IDD)?”. Retrieved from https://www.bca.gov.sg/IntegratedDigitalDelivery/Integrated_Digital_Delivery.html, accessed on 24/03/2019.