In the construction industry, ‘supplier’ is a very general term which refers to organisations contracted as part of the delivery of a built asset. Suppliers might have been considered to be organisations contracted to provide physical supplies such as goods, materials, plant, and so on, a supplier as any provider of services or goods either directly to the employer or to another supplier in a supply chain’. The ‘supply chain’ is the interconnected hierarchy of suppliers.

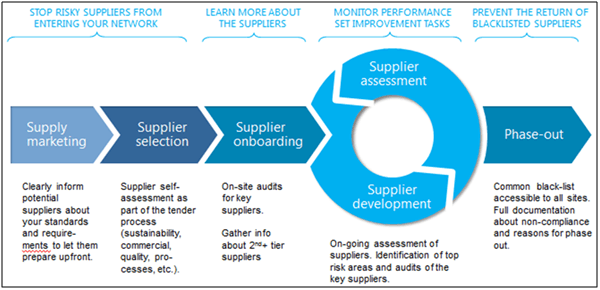

The supplier evaluation framework can help to set up a benchmark and corrective action plan for the existing supplier. Supplier Evaluation and Management had been practiced in manufacturing industry and Construction Projects. The most important criteria in construction industry is material quality, delivery dependability, and cost. The most important factor of supplier selection is the quality level of the procurement items. Below is a diagram showing supplier assessment as part of the Supplier Lifecycle.

Table of Contents

Good Communication with Suppliers

Knowing from the onset that the supplier is readily available for questions (i.e. Picks up the phone and responds to e-mails quickly), lays a great foundation for a customer-supplier relationship. It should be clear who the main contact person will be, as well as his capability to effectively communicate your needs with his own team. It is also important that should problems arise, you have the ability to speak with senior executives on the team.

Competency and Capacity

Check out the suppliers’ capabilities against your needs. Most of these service lists are available on their websites or in brochures, but talking to account heads or agents personally will give you an even further look into the true expertise of the supplier. Getting information from other customers similar to you will also be of big help.

You have to assess whether the supplier has the capacity to handle your requirements and how quickly they can deliver to you. How do they handle fluctuations in supply and what are their resources to service all customers?

Commitment and Control

Check their commitment to provide only products of the highest quality. Do they qualify within the standards of Six Sigma or ISO 9001? They should also signify that they are committed to you, as their customer, on a long-term basis.

Inquire about how much control the supplier has over the supply chain, the procedures and the processes. How can they ensure that delivery of goods to your company will remain reliable and consistent?

Cost and Cash flows

This pertains to their pricing scheme. More often than not, supplier comparisons depend greatly on this, but be sure to keep in mind that cheap does not always equate to high quality. The pricing is ultimately just one of the factors to consider when choosing suppliers. A supplier can effectively deliver on clients’ expectations when they have a good state of finances. Ask for proof of the strength of their finances and make sure that they can weather economic uncertainties.

Consistency, Culture and Cleanliness

Can the supplier consistently provide high quality goods? A good basis for this is to ask how long they have been working with their other clients. If they have long standing relationships with other clients, it is a good sign that they can continuously deliver over time. As much as company culture is important to your business, it should also manifest in your supplier. Values such as speed, quality, excellence, innovation, and reliability are existent in trustworthy companies and you want to be sure that the same can be said about your own suppliers.

Are your supplier’s production methods sustainable? Are their processes environment friendly and are they ethical in the way they treat their employees? Are they capable of handling growth and able to expand as your business expands too? Keep all the information you gather about your suppliers in an easy-to-understand table format, and it should be easy for you to identify the supplier that suits your needs perfectly.

Developing Reliable Relationship with Suppliers

Communications is open and robust goes a long way towards keeping you and your suppliers on the same page. Transparency in each other’s operations also helps to build trust and understanding in the partnership, it also helps to understand their language and culture to avoid any communication breakdown. A Solid Agreement is required before agreeing into a supplier-retailer partnership, always ensure that you and your suppliers agree on a clearly crafted contract where terms are defined and responsibilities drawn our plainly. It will eliminate on any conflict or disagreement should there be any problems occur.

A Supplier Relationship Management Program is similarly like any other aspect of your business, strategies are required for a structured relationship with your suppliers. Treat them fairly and not to abuse the power as a buyer. Determine the supplier relationship management goals which is measurable and achievable within time frame, list our activities and process to attain goals and establish roles.

Performance Management Involved at the highest executive level is key to the ongoing success of the SRM program. While lower levels are much more involved in tactical operations and may interface with suppliers on a daily or weekly basis as appropriate to manage business, executives may only meet quarterly to discuss strategy. SRM program can work successfully on a day-to-day basis while continuing to evolve and address the long-term goals of both parties.

Training is necessary to educate the organization on its benefits and role in optimizing business operations. As large-scale SRM programs require management at different level to anticipate, every employee involved must be trained on how to use tools to ensure successful program execution. Before SRM is even rolled out, the employees should understand their role and obligations to the program for the greatest level of success.

Categories of Supplier Evaluations

The two main categories of supplier evaluations are process-based evaluations and performance-based evaluations. The process-based evaluation is an assessment of the supplier’s production or service process, and performance-based evaluations are based on objective measures of performance. Typically, the buyer will conduct an audit at the supplier’s site to assess the level of capability in the supplier’s systems.

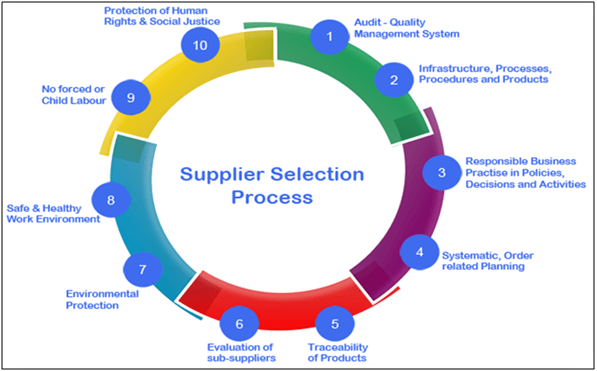

In the construction industry, material quality, delivery dependability, and price appear to be the most critical criteria. However, the degree of importance that various construction firms place on the four criteria varies. The supplier selection process begins by choosing potential supplier for each material type needed for a specific project. The selection process is usually based solely on past performance.

Quality, Cost, and Delivery (QCD)

Product quality should consistently meet specified requirements since it can directly affect the quality of the finished goods. Unit price should not be the only criteria in supplier evaluation. Total cost of ownership is an important factor. Total cost of ownership includes the unit price of the material, payment terms, cash discount, ordering and carrying cost, logistics and maintenance costs, and other more qualitative costs that may not be easy to assess.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Ben Ng Boon Hee, DPSM. (2018). “Key Strategies to Enhance Supplier Relationship”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-strategies-enhance-supplier-relationship, accessed 15/12/2019.

Kim O’Shaughnessy. (2019). “Enterprise-resource-planning/ERP -advantages-and-disadvantages”. Retrieved from https://selecthub.com/enterprise-resource-planning/erp-advantages-and-disadvantages, accessed 15/12/2019.

Nurazyyati Jaffar, ADPSM. (2018). “Key-Strategies-Build-Effective-Supplier-Relationship-Management”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-strategies-build-effective-supplier-relationship-management, accessed 15/12/2019.

Stephen Whitehouse. (2019). “Advantages-of-Building-a-Supplier-Relationship”. Retrieved from http://www.winman.com/blog/advantages-of-building-a-supplier-relationship, accessed 15/12/2019.