Safety measurements such as global lockdown, social distancing, and other measures are introduced to restrict the spread of the COVID-19 pandemic, which has urged consumers are bringing the shopping experience closer to the digital front. Supply chain management is a link between customer and manufacturer. Reverse logistics is a type of supply chain management that returns goods from customers back to the sellers or manufacturers. It is a set of activities related to the reuse of products and materials which involve returning commodities due to damage, seasonal inventory, salvage, recall, and excess inventory to the manufacturer or forwarding it for servicing, refurbishing, and recycling. With the rise of e-commerce on the global platform, digital commerce is constantly transforming and becoming more and more demanding. It is essential to streamline reverse logistics process as it results in huge benefits such as cost reductions, pleasant customers, and less environmental waste.

Table of Contents

Enhancing Customer Satisfaction

Customer satisfaction is always a concern in the success of e-commerce. Exchange and return policy bring a positive and significant influence in customer satisfaction for repurchasing. Reverse logistics handles the return of products to sellers or manufacturers due to faulty units or customer dissatisfaction. Process without much fuss results in greater customer satisfaction and maintains the business’ bottom line in the long run. Both e-commerce and brick-and-mortar retailers can improve customer satisfaction with policies that provide a full refund, receipts, and original packaging not required. At the same time manufacturers will organize, retrieve, and determine the outcome of the returned product and ship the new product to customers. Reverse logistics also can be a source of valued information to help the company in identifying the issues and analyzing the data of returned products to enhance customer satisfaction by improving quality during the design phase.

Increasing Asset Utilization

Reverse logistics plays a critical role in an organization as it helps in maximizing asset utilization and minimizing costs or liabilities by classifying and disbursing products or assets that fall under surplus, scrap, excess, obsolete and waste status efficiently and accurately. There is always a misconception that products returned to the manufacturer are junk and ready for disposal. However, manufacturers will identify the failure reason and forward the returned products to repair, refurbish, or remanufacturer the product to like-new condition and recover it as an asset of the company. The manufacturer will congregate various functional components from end-of-life products to reuse in other new manufactured products. An efficient reverse logistics program can turn unwanted products into unforeseen assets. This can be done by restoring the loss of investment in the failed products such as repairing the units or placing the repurposing products in a secondary market for sale. The values of returned products can possibly turn also into a new business opportunity.

Generating Better Return on Inventory (ROI)

Reverse logistics can be used to smoothen and expedite the procedure of returns and goods replacement to reduce inventory requirements. This will also reduce the amount of capital hooked up in the inventory leading to significant improvements in ROI. It is crucial to have an advanced analytics system in place to avoid an accumulation of return products as well. Analysis of patterns in sales, returns, and complaints aid assimilation of products and practices as per customer demands.

Reverse logistics practices can gain additional ROI as well from the end-of-life products especially electronics devices and IT equipment. The high amount of metals contains in electronic components such as copper, iron, or steel are easily resold to make new units. Well managed reverse logistics can convert liabilities into assets and generate a healthy return on inventory by working closely with suppliers to sort or vet the returned products properly. Over the years, many channels have been developed to dispose of goods that returned by customers. This creates a favorable impact on the profit-maximization process.

Reducing Losses and Unplanned Revenue

Efficient reverse logistics processes help in reducing losses in various cost areas which include transportation cost, storage cost, returns labor and costs associated with fraudulent returns. Streamlined return management contribute to company productivity through proper planning, implementing the most efficient and cost-saving process flows, from the collection of goods returned to the manufacturer.

Reverse logistics is highly prioritized for vary of industries especially the manufacturing industry that contains lots of components and parts that can be remanufactured or recycled. Manufacturer can implement automated process management to improve traceability and put the necessary effort into finding out roots causes and finding solutions to diminish the impact. This may require the advancement of initiatives to improve manufacturing, storage, transportation, and customer service in relation to outbound product supply.

Improving Environmental Sustainability

Used electrical components and hazardous materials are harmful to the environment. Environmental aspects are one of the important elements. Green reverse logistics aimed to reduce the environmental externalities, through the deal with logistics-related aspects including transportation, warehousing, and inventories to reduce environmental issues like greenhouse gas emissions in logistics operations, noise, and accidents. The green design refers to the product will be considering the impact on the environment, for instance, the used material, and it is recyclables or not when the products end their service life.

Eco-friendly reverse logistics focus on managing the products, components, and materials that have been used and discarded. Reduction of the final amount of waste will be noticed especially when it works with scrapped products. Consuming fresh raw materials in brand new manufactured products will also decrease. Misuse of unprocessed raw materials can prevent with reuse of materials in the manufacturing process and results in a reduction of less power usage and lower levels of air and water contamination. This practice will directly benefit society as well.

Promoting a Culture of Circularity

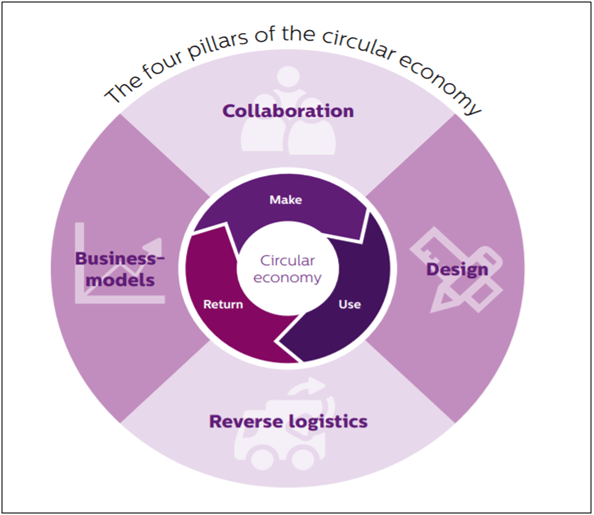

Reverse logistic involves the collection of goods, transportation to a designated location and sorting prior to remanufacturing, refurbishing, reusing, recycling, or disposal. The concept of reverse logistics is one of the pillars of the circular economy. It plays an important role in the process of transition to a circular economy.

Circular economy aims to present a circular system where the value of materials, resources, and products are preserved in the economy for as long as possible. Circular economy intends to foster economic growth in a way that diminishes environmental impacts as well as usage of limited resource consumption by improving quality and preserve the value of components, materials, and products. This includes make sure that products and materials can be reused, remanufactured, recycled, or repaired in the product design phase.

Conclusion

Reverse logistics will be one of the efficient ways to reduce costs, increase revenues and customer service levels, and obtain the market advantage result to improve visibility and profitability for the company. Factors to measure different aspects of the reverse logistics process must be evolved and implemented to accomplish this task.The fast pace of life increased the customer demand for efficiency and effectiveness of logistics, especially reverse logistics. Companies with successful reverse supply chains are those that closely collaborate with the forward supply chain and creating a closed-loop system. Companies that address the reverse supply chain in circular system will not only gain business efficiencies but also competitive advantages.

References

Clover Lee, PDLM. (2019). “The Reverse Logistics for Plastic Materials”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/reverse-logistics-plastic-materials/, accessed 07/12/2021.

Emy Ezura A. Jalil. (2019) “Customer Satisfaction and Reverse Logistics in E-Commerce: The Case of Klang Valley”. Retrieved from https://20191207190137_OSCM_2019_paper_102.pdf/, accessed 08/12/2021.

Janusz Grabara, Marina Man, and Michal Kolcun. (2014). “The benefits of reverse logistics”. Retrieved from https://www.scipress.com/ILSHS.26.138.pdf, accessed 01/12/2021.

Lai Wan Voon, ADPSM. (2020). “Three Critical Enablers for Circular Supply Chain”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/three-critical-enablers-circular-supply-chain/, accessed 12/12/2021.

Morgan Forde. (2020). “Gartner: Circular supply chain investments must focus on reverse logistics”. Retrieved from https://www.supplychaindive.com/news/circular-supply-chain-reverse-logistics/573078/, accessed 05/12/2021.

Theresa Pang Kim Lian, DLSM. (2019). “Key Considerations for Reverse Logistics Operations”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/key-considerations-reverse-logistics-operations/, accessed 07/12/2021.

Vipasha Singh. (2020). “Step up ROI from Reverse Logistics in Supply-chain Management”. Retrieved from https://erpsolutions.oodles.io/blog/reverse-logistics-supply-chain-management/, accessed 03/12/2021.

Winnie Teh Cheng Hoon, DLSM. (2021). “Evaluating Lean Performance for Reverse Logistics”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/evaluating-lean-performance-reverse-logistics/, accessed 07/12/2021.