Reverse logistics is the set of activities that is conducted after the sale of a product to recapture value and end the product’s life cycle. It typically involves returning a product to the manufacturer or forwarding it on for servicing, refurbishment or recycling.

Table of Contents

Environmental Impact of Plastic Pollution

Marine litter, consisting of between 60-80% plastics, is now seen as a major anthropocentric stressors to the ocean and its biodiversity (United Nations Environment Program, 2019). With an estimated 500 million people, as well as industries worth billions of dollars dependent on healthy reef ecosystems, the continued decline in coral cover and shifts in community composition globally are an extremely worrying trend from economic, social and ecological perspectives. It was estimated that, based on extrapolated data, reefs and their organisms will have been exposed to 15.7 billion macro plastic items by 2025, under ‘business as usual’ scenarios. This represents a 40% increase from 2010 levels.

Plastics which can contain toxic chemicals when ingested are now suspected to be part of our food chain. Karami et al. (2017) found a widespread distribution of micro plastics in aquatic bodies, which in turn contaminated a diverse range of quatic biota, which included those sold for human consumption such as shellfish and mussels. They suggested that, annually, humans consuming dried fish and shellfish could ingest up to 246 pieces and 11,000 pieces of microplastics respectively, hence leading to the conclusion that seafood products could be a major route of human exposure to microplastics.

On land, the disposal of plastics through incineration releases toxic gases such as Dioxins, Furans, Mercury and Poly chlorinated Biphenyls into the atmosphere (Verma et al., 2015). These toxic substances released pose a threat to vegetation, human and animal health and the environment as a whole, with increases in risks to human health due to a higher risk of heart disease, aggravated respiratory ailments such as asthma and emphysema, causing rashes, nausea or headaches, and damage to the nervous system.

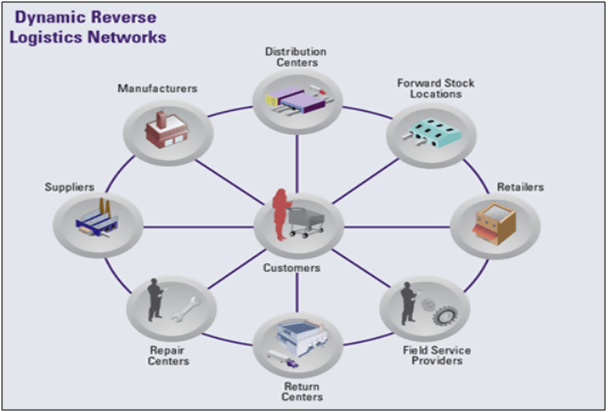

Create dynamic reverse logistics networks

In order to optimize performance, reverse logistics functions must operate in an integrated manner across both tactical and operational decision horizons. Due to the variability in supply and demand patterns, close linkages between planning and execution will result in a dynamic decision support framework that optimizes inventory positions and reverse supply chain processes based on real-time conditions. The ability to push the disposition decision as close to the inception of the return as possible, and the flexibility to coordinate extended reverse logistics processes allows industry leaders to move from static to dynamic reverse logistics networks.

For example, a large contract repair and reverse logistics service provider has linked return forecasting and planning with dynamic decision making to optimize the disposition and routing of product returns. Forecasting return and repair conditions provide better insight into the long-term capacity requirements needed to process returns. Integrating decision support at the operational level allows the service provider to optimize the return flow based on real time conditions such as service levels, repair capacity, inventory positions, and demand patterns across the network.

The result: competitive advantage by providing reverse logistics services that are better, faster, and cheaper than the competition.Whether you are a brand owner, OEM or reverse logistics service provider, integrated reverse logistics provides new ways to streamline operations, drive profits, and delight customers.

Technology In Reverse Logistics

Apps can help facilitate returns. There are apps for that these days. Some are designed to facilitate product returns and even give instant refunds, others help customers compare their shipping options for return shipments so they can make a choice that’s easiest for their lives and schedules.

Automating inventory solutions. Too many reverse logistics companies continue to grade products by hand, which is a slow and tedious process. There are SaaS solutions today that take the guesswork out of grading returns and instead give a definite decision quickly. Whether the answer is to refurbish, reroute, liquidate or scrap, automating returns sorting not only makes it go faster, it turns out that it’s helping to keep more goods out of landfills.

Opening direct sales channels for liquidation. Online auction platforms will sell just about anything these days, and there’s one specifically for liquidating returns and products that have been discontinued. Instead of hoping for a buyer, retailers can list their products for sale, receive multiple bids from across the globe, make arrangements for transportation and net more money than they could by selling locally.

Benefits of an Efficient Reverse Logistic Operation

While many companies consider the return process to be a necessary evil that shouldn’t be noticed, companies that implement an effective reverse logistics workflow can reap several benefits.

Some of these benefits are:

o Reduced costs. By planning ahead for returns and making the return order right, you can reduce related costs (administration, shipping, transportation, tech support, QA, etc.)

o Faster service. This refers to the original shipping of goods, and the return or reimbursement of goods. Quickly refunding or replacing goods can help restore a customer’s faith in a brand.

o Customer retention. Dealing with errors is just as important as making sales. If a customer had a bad experience with your product, you have to make it right. Fulfilment blunders can create educational opportunities. Learn how to keep your customers happy and engaged with your company – even after you’ve made a mistake.

o Reduced losses and unplanned profits. Recover the loss of investment in your failed product by fixing and restocking the unit, scrapping it for parts, or repurposing it in a secondary market. With a good reverse logistics program in place, you don’t have to leave money on the table. Take a product that would otherwise just cost your company money and turn it into an unforeseen asset.

Conclusion

Increasing rates of customer returns and the financial burden of processing them has driven many supply chain operators to evaluate the potential of reverse logistics in their supply chain network the possibilities and the benefits are endless if endless if executed properly. Consider both how your system currently operates and how it can be improved with the implementation of standardized returns processing. Effectively implementing a reverse logistics program can help your operations to attract and retain clients, save money, reduce inventory waste and much more.

References

3ccontactservices. (2016). “Top 14 Reasons Why Customers Return Purchases”. Retrieved from https://3ccontactservices.com/top-14-reasons-customers-return-purchases, accessed 13/09/2019.

Clover Lee, PDLM. (2019). “The Reverse Logistics for Plastic Materials”. Retrieved from SIPMM: https://sipmm.edu.sg/reverse-logistics-plastic-materials, accessed 15/09/2019.

Datex. (2017). “Supply Chain Management Basics: Reverse Logistics”. Retrieved from https://www.datexcorp.com/supply-chain-management-basics-reverse-logistics, accessed 13/09/2019.

Ho Kek Ming, DLSM. (2018). “Six Essential Areas for an Integrated Logistics System”. Retrieved from SIPMM: https://sipmm.edu.sg/six-essential-areas-integrated-logistics-system, accessed 11/09/2019.

Newcastle System. (2017). “The Importance of Reverse Logistics in Your Supply Chain”. Retrieved from https://www.newcastlesys.com/blog/the-importance-of-reverse-logistics-in-your-supply-chain,accessed 13/09/2019.

Shippr. (2015). “Reverse logistics”. Retrieved from: https://medium.com/@shippr/reverse-logistics-12-a0e094c34fad. accessed 10/09/2019, accessed 11/09/2019.

Smarteturns. (2018). “3 Approaches to Using Technology in Reverse Logistics”. Retrieved from: https://smartreturns.com/3-approaches-to-using-technology-in-reverse-logistics, accessed 14/09/2019.

Spring. (2016). “Reverse logistics”. Retrieved from: http://www.rlmagazine.com/edition02p26.php, accessed 13/09/2019.