Measuring procurement performance is an important role in an organization especially in supply chain during an economic downturn. Procurement not only encompasses role of acquiring goods and services which actually done by purchasing department, in fact, procurement responsibility is to explore and create strategies which align to business goals, mission, and objectives of an organization. First of all, we need to understand the differences between procurement and purchasing. Procurement involve the strategies, implementation of purchasing as well as interact with internal customers and external suppliers. Purchasing is more like a routine task of acquiring goods and services to help organization to maximize it output performance of incur minimum cost of purchase.

Table of Contents

Fundamental of Procurement

For an organization to stay competitive in marketplace, purchasing role is crucial as a cost reduction in raw material can allow organization to competitively market the price of their finished goods in order to win the business or order. There is numeric performance measurement that organization can use when evaluating their procurement performance.

Procurement KPI Management Tools

Procurement Performance Measurement play a role as an integral component of procurement management and it closely related to spend management. Spend Management is a processes, key indicators and methods of how we collect data, process information and evaluate data to reduce procurement costs, which are necessary for measuring procurement success.To determine how well the system is functioning, manager need to ensure their procurement system performance is always updated and all the information is under control and confidential.

An additional advantage of evaluating procurement management performance is that it enables organization to identify which areas need to be improve or enhance procurement performance processes. To effectively monitor procurement performance, organization must choose an appropriate performance monitoring indicator, thus it can collaborate and supported by both management and operational personnel. Throughout the understanding of procurement performance process via spend management and realization of procurement initiative, the finding we can observed is maximizing saving and bring profitable benefit to an organization.

Balance Scorecard Approach

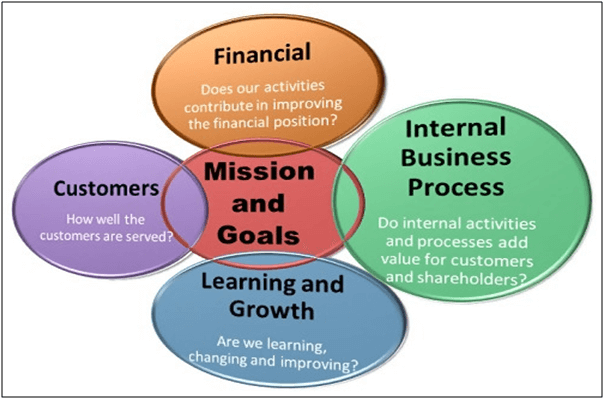

In procurement strategic management, balance scorecard is most widely used to identify and improvement various internal functional departments and their resulting external outcomes. Furthermore, balance scorecard approach also support for forecast planning and management system which used to align a business’s activities with the business goal. It aims to decode some of the vague ambition included in organizations vision or mission statement into practicalities of how to manage the business better.

A balance scorecard is a performance measurement framework which values added in strategic of non-financial performance. It measures of traditional financial metrics and provide a more balanced” view of organizational performance.

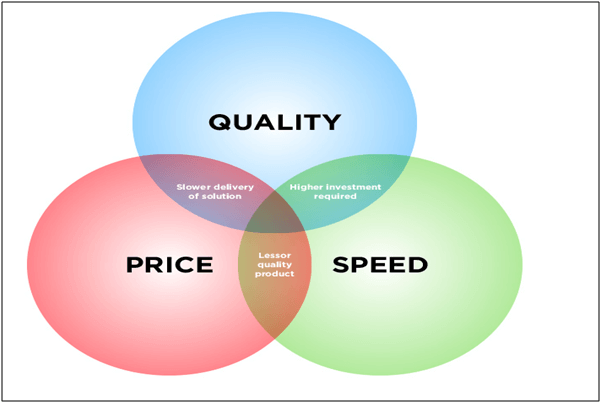

QDC (Quality, Delivery & Cost) Performance Indices

A performance index is a single measure of a system’s performance that emphasizes those characteristics of the response that are deemed to be important. Performance indices are derived based on the trade-off between a constraint and the free variable. Performance Index is a measurable value that demonstrates how effectively a company or functional department is achieving key business objectives.

o Quality Performance Indices: Identify performance of goods or services using certain attributes to improving level of quality.

o Delivery Performance Indices: Delivery performance provides an indication of how successful the supply base is at providing products and services to the concerned stakeholders. These metrics are most important in the measurement of performance of the procurement function.

o Cost Performance Indices: These are measures of the efficiency of expenses spent and also effectiveness of the procurement function on cost related aspects like actual cost spend and savings.

Purchase Order Cycle Time KPI

Purchase order cycle time is the KPI that covers from initial stage of purchase order creation to the final payment processes. It mainly focuses on the order cycle time.

Supplier Defect Rate KPI

This is one of the crucial KPI for procurement as it determines the final quality of a product delivered by supplier. This is to calculate the percentage of product received that do not meet the compliance specification and quality requirement. Supplier Defect rate is a critical KPI when it comes to measure some industries like aerospace and multi-tiered automotive. Constantly tracking different suppliers’ defect rates and break it down into different categories defect type will provide you a better insight on which supplier is performance better.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Datapine. (2019). “Procurement Key Performance Indicators and Metrics”. Retrieved from https://www.datapine.com/kpi-examples-and-templates/procurement, accessed 13/09/2019.

Martin Murray. (2017). “Measuring Purchasing Performance- Optimized Supply Chain Impact”. Retrieved from: https://www.thebalance.com/measuring-purchasing-performance-2221229, accessed 13/09/2019.

Mork Choo, DPMM. (2017). “Effective Procurement Practices in the Marine Offshore & Shipbuilding Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/effective-procurement-practices-in-the-marine-offshore-shipbuilding-industry, accessed 13/09/2019.

Philip Charles, PDPM. (2018). “Key Performance Indicators for Evaluating Purchasing Performance”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-performance-indicators-evaluating-purchasing-performance/, accessed 13/09/2019.

SN Panigrahi. (2017). “Procurement Performance Balanced Scorecard & QDC Approach”. Retrieved from TaxGuru: https://taxguru.in/finance/procurement-performance-balanced-scorecard-qdc-approach.html, accessed 13/09/2019.