Measuring Purchasing performance is essential for effective management and continued improvement of the purchasing function. Purchasing evaluation provides vital feedback to the purchasing department as well as top managements for assessing the effectiveness of an organization’s purchasing strategies and decision-making processes. Overall performance of an organization is strongly affected by how well the purchasing function can contribute to the firm’s strategies and goals.

Purchasing plays an ever increasingly important role in the supply chain especially in an economic downturn. Cost reduction of raw material and services can allow companies to competitively market the price of their finished goods to win in a business. An obvious performance measure of the success of any purchasing department is the amount of money saved by the company.

A better understanding of how purchasing professionals and internal customers evaluate purchasing performance is needed to improve the overall effectiveness and efficiency of the organization.

Purchasing Departments are tasked in sourcing goods or services at the best possible price with the Right Quality the Quantity the Right Delivery. The possibilities of procuring cheaper materials with quality desired from alternative sources as part of their daily activities.

Table of Contents

Evaluating Purchasing Performance

An organization would need a systematic approach if they want to efficiently evaluate the purchasing performance which may lead to the following benefits:

1. Better Decision Making – From identified variances of planned results and actions can be taken in the future to prevent further occurrences.

2. Better Communication – Such as analyzing certain invoices which would need an extra check that would lead to better payment arrangement procedures and improve understanding between purchasing and administration.

3. Better Visual – It makes things more visible with regular reporting against actual vs Planned this enables a buyer to verify whether their expectations have been realized.

4. Better Motivation – An evaluation system can meet the personal and motivational needs of each purchaser which can be used as constructive goal setting and developing personal programs in purchasing.

There are several performance measurements that businesses can use when they measure purchasing performance:

Purchasing Efficiency – Administrative costs are the basis for measuring purchase efficiency, this performance measurement does not relate to the amount purchased items that the department has procured but the measurement relates to how well the purchasing department is performing in the activities they are expected to perform against the budget that has been placed. If the purchasing costs are within budget, then the efficiency of the purchasing department has met its expectations. If the department is using funds over and above the budget then the purchasing function is not efficient.

Purchasing Effectiveness – Price that is paid for an item will not be necessarily a good measurement of performance. Prices may fluctuate due to market conditions, availability and other demand pressures in such situations purchasing departments may not be able to control the price A popular method of assessing purchasing effectiveness is to review the inventory turnover ratios. The ratio measures the number of times, on average that the inventory is used, or turned, during the period.

Purchasing KPI Management Tool

Purchase Management determine which activities are key areas and justify the effort of evaluation. Key Performance Indicators (or KPIs) are management tools designed to analyze procurement department performances to achieve goals, strategies and objectives. They are also crucial to ensure that procurement is sustainable and that purchasers are constantly looking for ways on how to improve procurement processes.

KPIs help to point in the direction where it improves performance levels. Improvement for more efficient and sustainable procurement processes. The three major groups of Purchasing KPI are Cost Savings, Quality, and Delivery of purchased items.

Cost Savings KPI’s

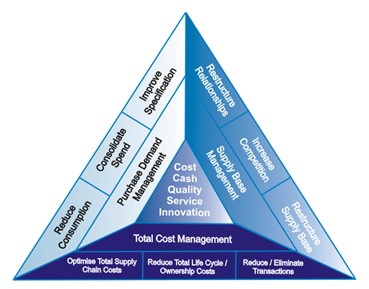

Measuring the percentage of managed spend against total spend on purchases for external products and services. Managed spend can be calculated as the sum of all spend run by an organization. Goal of this KPI is to have more spend standard procedures, thereby saving on costs. And Reducing Consumption to determine if it’s necessary, an organization can exclude things that they can they can do without or substitute, for example the reduction of travel expenses by deployment of video conferencing. Consolidation of spend hidden costs can arise if specifications are harmonized such as Mobile Phones laptops and lease cars which could lead to savings. From suppliers, Improving competition among suppliers for cost saving, generating higher competition among suppliers, By using benchmarking and comparing supplier participation rate results.

Quality KPI’s

Products and services of low quality would affect an organizations product quality which might add additional costs. KPI quantifies the purchase quality of the procurement branch. Metrics such as percentage of rejections, goal is to lower these percentages, rejected services from service providers, lowering the disapproval rate. Seller rejection rate rejected goods which is important if it directly affects customers. Disruptions due to low quality, if the company is facing continuity disruptions due to low quality focus on increasing the quality of strategic materials. Setting a lower end quality standard for each article and the goal is to follow the quality standards.

Delivery KPI’s

To establish strategies that can improve delivery as well as continuity of supply. Strategic supply is important for organizations, late deliveries might affect supply chain continuity, early deliveries can result in higher operational/Inventory costs. The goal is to have lower number of errors against the requested time frame for deliveries. Deliveries that are on time helps to Maintain continuity, improve inventory management which leads to cost savings. The Accuracy of purchase orders is the outcome of suppliers delivering the right quantity of right goods. Inaccurate purchase orders might result in additional inventory or operational costs and shortage in quantity can interrupt continuity.

Factors Influencing Purchasing performance

Factors that influences purchasing performance measurement. It’s how an organizations management looks at the role and importance of function. Management evaluates purchasing operations on parameters such as

Operational and administrative activity: Management evaluates purchasing operations primarily on parameters such as order backlog, administrative lead-time, number of orders issued, numbers of requests for quotations issued, adherence to existing procedures, etc.

Commercial activity: Management is aware of the savings potential which purchasing may represent. Parameters being used here are the total savings reported by purchasing, number of quotations issued, variance reports, inflation reports, etc.

Part of integrated Logistics: Management becomes aware that price hunting has its drawbacks and may lead to sub-optimization. Evaluation is aimed at quality improvement, lead time reduction and improving supplier delivery reliability.

Strategic business area: Purchasing is actively involved in deciding the company’s core business and reinforces the company’s competitive position. Management evaluates purchasing amongst others on the number of changes in its supply base, number of tenders and e-auctions, and its contribution to the bottom line in terms of savings realized.

Establishing KPI

An organization should figure out what stakeholder’s interest is and along with the company’s strategies and future objectives. KPI’s are usually customized, looking for metrics that reveal progress towards achieving goals.

Analysis of the data: management should look for interrelationships between means and ends.

Following the analytical stage, various measures are developed, implemented and subsequently refined. Prevent measures becoming too complex and too numerous, as simplicity is key.

KPIs should be relevant to your business or department and simple to use. Key Indicators of five or six would be enough, and not being overwhelmed by data it should not be about taking hours gathering data.

Conclusion

There is no one-size-fits-all formula for every company. Goals as well as KPIs are most usually custom. Several studies have been carried out on purchasing performance and the results are that there is no one method that will cover every purchasing department. However common key area measures that is found to be common in evaluating performance. Namely, cost saving, vendor quality, delivery metrics and price effectiveness. Although these key measures are common, the weight placed on these measures are by no means uniform and will vary between industries, businesses and services. In addition, the importance of these measures to the overall effectiveness of a purchasing department will change over time and therefore need to be assessed and modified periodically.

References:

A. J. Van Weele. (1994). “Purchasing Management analysis, planning and practice”. London International Thomson Business Press.

Kenneth Hamlett. (2010). “What Are the Key Performance Indicators for a Purchasing Department”. Retrieved from http://smallbusiness.chron.com/key-performance-indicators-purchasing-department-1066.html, accessed 1/12/2017.

Lee Shui Cha Sylvia, MSIPMM. (2017). “Key Success Factors for an Effective Procurement or Purchasing Process”. Retrieved from https://publication.sipmm.edu.sg/key-success-factors-for-an-effective-procurement-or-purchasing-process, accessed 28/11/2017.

Martin Murray. (2017). “Measuring Purchasing Performance- Optimized Supply Chain Impact”. Retrieved from https://www.thebalance.com/measuring-purchasing-performance-2221229, accessed 28/11/2017.

Martin Putters. (2013). “How To Measure Procurement Savings”. Retrieved from https://www.capgemini.com/consulting/2013/09/how-to-measure-procurement-savings, accessed 30/11/2017.

Mork Choo, MSIPMM. (2017). “Effective Procurement Practices in the Marine Offshore & Shipbuilding Industry”. Retrieved from https://publication.sipmm.edu.sg/effective-procurement-practices-in-the-marine-offshore-shipbuilding-industry, accessed 28/11/2017.