The techniques applied to a supply contract vary depending on the type of the work and the nature of the industry. Contract technique can be defined as determining the best contract arrangement to best facilitate procurement of goods or services, in alignment with the requirements and company objectives. A “one size fits all” approach to the form of contract is unsuitable and ineffective. It is crucial to tailor-make a contract that is appropriate – reflecting the size, nature, value and complexity of the requirement/project and also fitting to the relationship required with the suppliers.

A Supply Contract is an elaborated agreement between two or more parties where one or more parties (the seller) may provide products or services in return for something offered by other parties (the buyer). Contracts detail the terms and conditions of a particular project/supply. An inaccurately formed contract could cost you money over a period of time. If a contract is inadequate, you may need to spend money to get the other party to legally comply or pay extra because you opted for a time and materials procurement contract instead of one with a fixed price.

Table of Contents

Fixed-Price Contract

With this type of contract, the seller agrees to provide their service or product at a set price, independent of resulting equipment, material, and labor costs. This means that the seller will bear any costs beyond the agreed-upon amount. This type of contract has the least risk for the buyer. A well-defined scope and statement of work and a selection of competitive bidders help control pricing for this type of contract. Fixed price contract is most suitable if you have a clearly defined scope of work.

1. Firm Fixed Price (FFP)

This type has detailed requirements and a price for the work. The price is negotiated before the contract is finalized and does not vary even if the contractor needs to expend more or less resources than planned. Firm fixed price contracts require the supplier to manage the costs of the work in order to make a profit – this reduces the administrative burden on the buyer by eliminating the buyer’s responsibility to monitor supplier costs.

2. Fixed Price with Incentive Fee (FPIF)

FPIF is a contract type that provides an incentive to the seller/contractor for performing on the project above the established baseline in the contract. But often, this type also may include a penalty clause if the work is not performed according to the contract. The incentive would motivate the supplier/contractor to control costs to and meet the objectives.

3. Fixed Price with Economic Price Adjustment (FP-EPA)

This contract is fixed price contracts but they contain a provision to account for contingencies and changing costs due to inflation. This is suitable for long-term contracts for commercial supplies during a period of high inflation.

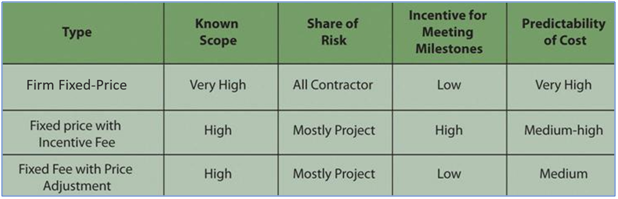

The 3 major Fixed Price Contract variants can be summarized below:

Cost Reimbursable Contract

A cost-reimbursement contract is a contract where a supplier/contractor is paid for all of its allowed expenses to a set limit, plus additional payment to allow for a profit. Cost overruns are an unavoidable risk of the cost-reimbursement-type contract; therefore, costs must be detailed and should be classified as direct or indirect costs.

The cost-reimbursement contract is considered high risk for the buyer because of the potential for cost escalation. As such, cost reimbursement contracts are suitable only when the cost of the work to be done cannot be estimated with sufficient accuracy to use any type of fixed-price contract.

1. Cost Plus Incentive Fee Contract (CPIF)

CPIF contract, the supplier will be reimbursed for all costs plus an incentive fee based upon achieving certain performance objectives mentioned in the contract. This incentive will be calculated using an agreed on a predetermined formula. The risk lies with the buyer; however, this risk is lower than the Cost-Plus Fixed Fee.

2. Cost Plus Award Fee (CPAF)

In CPAF, the supplier is paid for all his legitimate costs plus some award fee. This award fee cannot be appealed and will be based on achieving satisfaction according to certain performance objectives described in the contract. Award fees should be based on exceeding acceptable quality levels and are best used with performance-based contracting.

3. Cost Plus Fixed Fee Contract (CPFF)

In CPFF, the seller is paid for all incurred costs plus a fixed fee (which will not change), regardless of his performance. Buyer bears the risk. This type of contract is used in high-risk projects.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Andrew Krzmarzick. (2013), “Why Federal Contracting Should Be More Like Made-From-Scratch vs. Store-Bought Cookies”. Retrieved from: http://www.integritymc.com/blog/2013/06/why-federal-contracting-should-be-more-like-made-from-scratch-vs-store-bought-cookies/, accessed 10/09/2018

Clarence Tein. (2017). “Critical Issues to Avoid Procurement Fraud”.

Retrieved from SIPMM: https://publication.sipmm.edu.sg/critical-issues-avoid-procurement-fraud/, accessed 30/8/2018

Fahad Usmani. (2013). “Types of Procurement Contracts used in Project Management”. Retrieved from: https://pmstudycircle.com/2013/12/types-of-procurement-contracts-used-in-project-management/, accessed 03/09/2018

Lee Huan Peng. (2017). “Mitigating Key Supply Chain Risks and Disruptions” Retrieved from SIPMM: https://publication.sipmm.edu.sg/mitigating-key-supply-chain-risks-and-disruptions/ accessed: 04/09/18

Up Counsel. (2018). “Different Types of Procurement Contracts: Everything You Need to Know”. Retrieved from https://www.upcounsel.com/different-types-of-procurement-contracts, accessed 10/09/2018