Integrated facility management procurement process is a process of integration within an organisation, taking care of maintaining and developing the agreed services which support and improve the effectiveness of its primary activities.

The purpose for a procurement process of Integrated facility management is to select the best bidder who can deliver the services required by the client over a defined term, at a price that is acceptable by the client, with optimal legal and commercial terms acceptable by both parties.

Table of Contents

Importance of Procurement Technique

Procurement Technique are important and best implemented at an early stage due to the impact on the procurement lead-time, and to ensure a realistic time frame and the expectation for contract award is achieved. The relationship between Integrated Facility Management and procurement within an organisation is increasing and this presents potential obstacles to overcome on the journey.

Using traditional procurement methods and methodologies to often complex and intangible facility management services which lead to disappointment during the process and failure to achieve procurement objectives. At this stage of the process, it is also crucial to decide which procurement technique is effective to use. Among the important factors to consider when deciding a procurement technique, will be the complexity of the types of facility services, and monetary value.

Open Tender Technique

Open tender allows any organisation to submit a tender to supply the goods or services that are requested. In General, an advert will be placed and showing that the contract is being tender, giving an equal opportunity for any organisation to submit a tender. For larger projects, there may be a pre-qualification process which includes pre-qualification questionnaires and interviews where a short-list of suitable organisation from the respondents who express their interest in the contract. Short listed company will then be invited to prepare tenders.

Open tender may be a slow and costly process, attracting tenders or expressions of interest from large numbers of organisation, some of whom may be entirely unsuitable for the contract will then cause the waste of a great deal of time, effort, and money. However, open tender shows greatest competition and has the advantage of allowing new and emerging organisation for their work and so can facilitate greater innovation.

Request for Quotation Technique

A Request for Quotation or RFQ is common in procurement process in which an organisation requests for quote from multiple suppliers or contractors for the purchase of specific products or engagement for service works. A Request for Quotation not just involves the price of the goods or services but also Information like payment terms, quality and quantity per item, lead time as well as contract length may be requested during the whole RFQ process.

RFQs often include the details specifications of that goods or services so that the supplier or contractor will be quoting the same items or services. The more detailed of the specifications, the more accurate the quote will be and comparable to the other supplier or contractor. In Addition, for being detailed in sending out an RFQ may be used as a legal binding documentation to the supplier or contractor.

Outsourcing Technique

Outsourcing is the complete transfer of a business process and risk to an independent external organisation. The reasons for outsourcing may be due to lack of expertise or manpower in the field of requested services as well as uncertain market situation at where the company is located, company’s efforts to restructure the process flow of departments, to achieve economies of scale as well as way to reduce costs from skilled labour to raw materials. Outsourcing can be deemed effective and thus successful when it helps an organisation to achieve better quality and quantity, delivery commitment, cost management, service level agreement, lower risk, and greater opportunity for an organisation in competitive position and greater customer satisfaction.

Negotiation Techniques

A well-planned preparation is the key to negotiate successfully. First, the procurement officer must do some research for common goods and services that is available in the market. While requesting for quotations, the procurement officer can then compare the offered prices and ensures that the supplier or contractor does not offer unreasonable price. By having a clear picture of the supplier or contractor background, which include financial capabilities, project references, BCA grading as well as professional certificates such as BizSAFE or ISO certificates, this will further gain advantage by having the knowledge for bargain power. With a strong grasp info of the supplier or contractor background, the procurement officer can then be more prepared and make the necessary planning to enter negotiation stage.

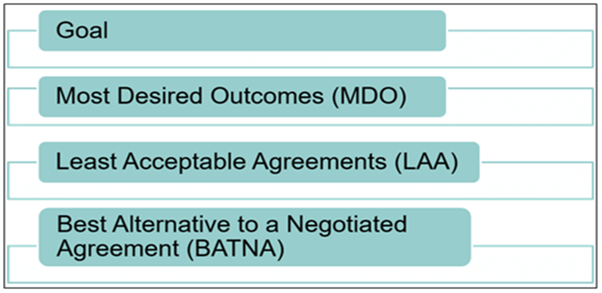

Following diagram shows the process flow of a procurement officer developing negotiating envelopes. Start from settings a goal, heaving the most desired outcomes, and dispatch over the least acceptance agreement, and end with the terms of looking at the best alternative and eventually accepts a final negotiated agreement.

Procurement Contract Technique

A procurement contract refers to a document detailing the legally-binding agreement with both the company (the buyer and the seller) who is promising to sell of goods and/or services with a detailed technical specification and to fulfil the terms and conditions stated in the agreement. The buyer in return is obligated to acknowledge the goods and or service and pay for liability created.

The purpose of the procurement contract is to ensure both rights and duties of each party in contract are provided to obtain the right quantity of input, of the right quality, at the right time as well as minimizing cost within budget.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

MR Industrial Services. (2020). “Ways To Improve Procurement Process In Facility Management”. Retrieved from https://mrindustrialservices.co.uk/ways-to-improve-procurement-process-in-facility-management/, accessed 13/12/2020.

Ravi Subramaniyam, DPSM. (2020). “Procurement Techniques for Metallurgical Products”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/procurement-techniques-for-metallurgical-products/, accessed 13/12/2020.

Teng Chooi Min (Manice), DPSM. (2020). “Negotiating Techniques for Construction Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/negotiating-techniques-for-construction-procurement/, accessed 13/12/2020.

Goh Chun Siang, DPSM. (2018). “Tendering Techniques for the Hotel Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/tendering-techniques-hotel-industry/, accessed 13/12/2020.

Tang Li Xuan, DPSM. (2018). “Essential Strategies for Successful Outsourcing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-strategies-successful-outsourcing/, accessed 13/12/2020.

Tina Wong WoanChuen, DPSM. (2018). “Five Essential Criteria for a Successful Procurement Contract”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-essential-criteria-successful-procurement-contract/, accessed 13/12/2020.

Sunil Hegde, DLSM. (2020). “Six Inventory Control Techniques for the Printing Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/six-inventory-control-techniques-printing-industry/, accessed 13/12/2020.