Printing industry is going through a metamorphosis due to digitalisation. From a traditional mass production, it is moving towards mass customisation and this trend must be fostered by the printing business world for its survival. The profits in this business which was over 25% a decade ago has since declined below 10%, hence making the business more competitive essentially this requires them to look inwards for cost-saving to improve their gains.

Table of Contents

Why Inventory control?

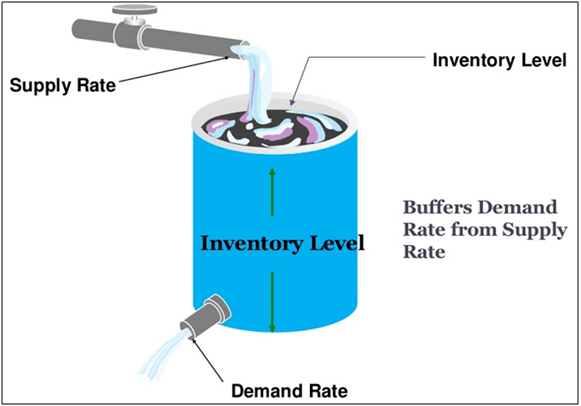

In this article six inventory control techniques have been prescribed which will improve the margins in the printing industry. Inventory control is based on a water tank analogy. The demand rate (production/sales) should be maintained uninterrupted by the inflow of required supply rate (inventory).

The key is maintaining inventory level to the lowest so the holding cost is low. In printing, there are four types of inventory, raw material inventory, spare part inventory, work in progress inventory and finished goods inventory. Raw material inventory forms more than 60% of the inventory cost.

Demand Forecasting

A predictable model for demand forecast is suggested for the printing business. This is to support their uniquely assorted print jobs. In book printing business, its inventory is more of a make to order production. There is a problem of obsolesce due to revisions which leads to scrapping and wasting resources. An improved forecasting will help in reducing waste, cost and ultimately improvement in the bottom line.

Due to an asymmetric information sharing between the printer and customers or distributors in a two-echelon supply chain and contract which generally favours the customer or distributors. This reduces considerable control on the entire supply chain and erodes printer’s profits. It is suggested to have more partnerships with the customers and distributors, which will motivate them to give more reliable forecast and help the business as a whole in managing inventory hold cost thus improving margins.

ABC Inventory Control Technique

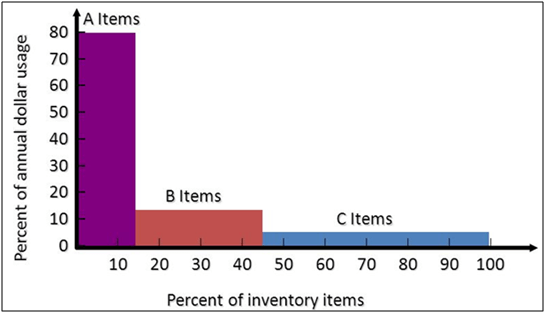

Always Better Control inventory is ABC. There are lots of inventories in a warehouse and it is not possible to deal with all objects the same. ABC is a technique that’s primarily based on placing merchandise into classes in order of importance. Important merchandise are categories the use of the ABC stock manage technique.The Pareto precept is used to classify the items. It is primarily based on the 80/20 rule, the regulation of the crucial few, which states that 20% of the items takes up 80% of the value.

- ‘A’ are products with the best possible annual consumption value. They are the top 70-80% of the annual consumption cost of the company for solely 10-20% of complete stock items. Tight inventory control is required, more secured storage areas and higher sales forecasts. ‘A’ inventories require to be monitored and see that there is no stock out.

- ‘C’ are products with the lowest consumption value. They are the lower 5% of the annual consumption cost for 50% of the total inventory items. Reordering is made less frequently.

- ‘B’ are the middle-class items, with a medium consumption value. They are 15-25 percent of annual consumption price normally for 30% of total inventory items. Class B requires monitoring as demand changes can also shift it closer to A or C.

Economic Order Quantity (EOQ)

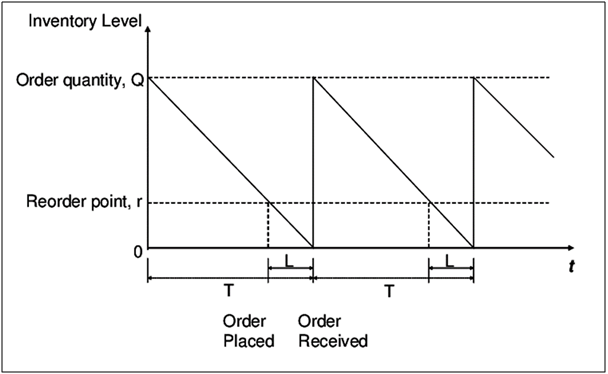

EOQ is a process to decide the ideal order volume level for stock to be ordered at a specific time. It’s additionally a formula that is used to decide the most efficient amount of items that have to be order and carrying cost may also be reduced to a minimum point. A company needs to place most beneficial orders, and neither too large nor to small. The EOQ is stage of inventory order that avoids stock-out and overstock and minimizes the total holding costs and ordering costs.

EOQ is a decision device used in cost accounting. It is a method that lets you calculate the reorder point, which is a degree of stock for a given product that triggers the want to confirm an order for fulfilling inventory. Thru the reorder point, business enterprise can avoid running out of inventory and able to fulfil all client orders. EOQ assumes that you order the identical volume at every reorder point. The EOQ model is a very simple one and its assumptions will be unrealistic in many applications, in exercise orders are not delivered instantly. The assumption of consistent utilization of stock and acknowledged annual demand is of doubtful validity.

Just-in-Time (JIT) Inventory System

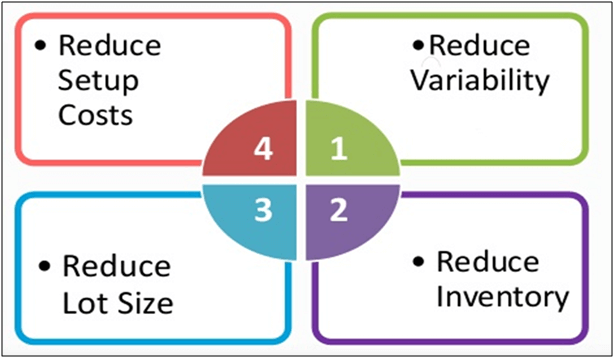

JIT inventory system makes production leaner, more cost-effective and customer responsive. With printing tending more towards on-demand and mass customisation, JIT inventory will help in meeting the needs of the customer and being more competitive. JIT inventory principle is basically to see that the correct amount of inventory like raw material, spare parts or finished goods are meeting the demands of production and in the end customers’ satisfaction.

JIT system works with pull system, which should be introduced throughout the plant to manage inventory flow at all levels. This pull system is also applicable to manage raw material flow into the process from suppliers. Introducing Kanban system at all levels of production is required for the pull system to work.

In JIT system supplier should be partners in supporting the pull system and replenish raw material when required at the right time. A need for multiple supplier will work well to meet demands. Suppliers are required to be JIT friendly and a change in mind-set is required.Implementing JIT inventory system requires mind-set change at all levels from senior manager, procurement manager to staffs working in production. Each one is the stack holder and is responsible to see that demand is fulfilled to the next process until it meets customer satisfaction.

First-In-First-Out (FIFO)

The FIFO inventory technique refers to the timing at which the stock is bought and subsequently used. Inventory that is purchased first is consumed in manufacturing earlier than stock that is purchased at a later date.FIFO helps reduce obsolete and ageing stocks. Obsolete stocks refer to inventory that is historical or outdated and is no longer suitable for sale or use in production. Many commercial enterprises require out of date stock to be written off from its bottom line after a predetermined period has elapsed. FIFO helps prevent obsolete or ageing inventory by the consuming of the stock first received earlier than using more recent inventory.

FIFO reduces the impact of inflation. Inflationary refers to the increase in the price of an item over time. FIFO can minimize the inflationary effect felt by the company, as the oldest inventory items are used. Assuming that inflation is constant, the buy price of the stock used in manufacturing or that is offered at retail was lower than the price of stock most currently purchased. Since direct materials expense is recorded at the purchase price of the stock used or sold, this value is decrease than if the present-day market price of the items had been used to report the expense.

FIFO ensures that the ending stock values on the balance sheet are indicative of present-day market expenses for the items. As items purchased at formerly dates are pulled from stock for production or retail sale, the inventory on the books at the end of the month consists of more recently bought inventory. This ensures that the ending stock on the balance sheet is reflective of present-day market prices.

Cycle Count Inventory Technique

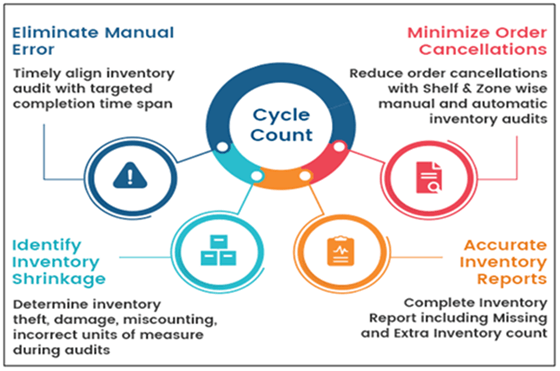

One of the key strategies of managing inventory in printing business is cycle count. Cycle count is additionally an inventory audit procedure. Cycle counting is completed by sampling solely some SKUs that represent the complete stock. The main focus is on high valued product or fast-paced stock keeping units (SKUSs). Cycle count is done daily, weekly or monthly. Cycle count has to be well managed and executed in a planned manner. Management support is much required.

Cycle count has its benefits:

- Reduced disruption in operations, no ought to shut warehouse.

- Errors reduces, as any error will be corrected within the next cycle.

- More assured purchasing choices and therefore it’s targeted.

- Avoids stock outs approach beforehand and creates reliable report.

- Savings on time and resources.

- Improved client service as consumer will be committed confidently and delivered in time.

- Improved Sales because of client trust with the corporate will be stronger.

Conclusion

A good inventory techniques will help the business in keeping their holding cost low, less inventory of ageing stocks and inventory damages. In printing, production manager should be responsible for the plants’ inventory control and he should work with the finance manager to see that profits are generated from the inventory.

References

Ali Siddiqi, (2016). “Five Important Technique for Effective Inventory Control”. Retrieved from https://publication.sipmm.edu.sg/five-important-techniques-for-effective-inventory-control/ , accessed on 15/03/2020.

Chong Yaw Wen, DLSM. (2019). “Essential Techniques for Inventory Control of Laboratory Equipment”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-techniques-inventory-control-laboratory-equipment/ , accessed on 15/03/2020.

Heizer and Render, Pearson Education Inc. (2011). “Just In Time and Lean Operation”. Retrieved from: https://www.slideshare.net/SINGHZEE/just-in-time-and-lean-operation-chapter-presentation , accessed on 03/03/2020.

Johnson, Justin. (2017). “The Advantage of the FIFO Inventory Method”. Retrieved from http://smallbusiness.chron.com/advantage-fifo-inventory-method-23485.html , accessed on 16/03/2020.

Lee Yi Xian, DLSM. (2019). “Inventory Control Techniques of Effective Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/inventory-control-techniques-effective-warehousing/ , accessed on 15/03/2020.

Terese Ong Yee Chiat, DLSM. (2018). “Five Important Techniques for Efficient Inventory Control”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-important-techniques-for-effective-inventory-control/ , accessed on 15/03/2020.