Smart technologies for warehouse operations are progressing at a rapid pace. Warehouses need to be equipped with the technologies that allow them to keep up with manufacture, production, and consumer demand. A smart warehouse is automated for improved productivity, efficiency, accuracy, and the solutions that are implemented give flexibility and capability to the employees and their processes. Technologies you should be using in your smart warehouse, with discussion on how to keep them flexible, functional, and effective. This article discusses smart technologies that can benefit more companies in warehouse operations.

Table of Contents

Automated Warehouse Technology

Technology is making many warehouse processes more efficient by augmenting the work of humans or automating tedious, manual tasks. Warehouse automation takes many types, including machines and robots that aid workers with processes related to inventory from when it arrives at the warehouse until it leaves. Robots are becoming more and more common in the world of warehouse automation.

Companies are using robots to make their jobs safer, more efficient, and more accurate. But that does not mean robots are taking over or stealing jobs from human workers humans are still part of the scene. Warehouse operations, managing a variety of processes and tasks to manage inventory and distribute goods. Many technologies that assist human workers or handle tasks from end-to-end fall under the umbrella of warehouse automation. Warehouse automation solutions are equally varied, consisting of several types of technologies.

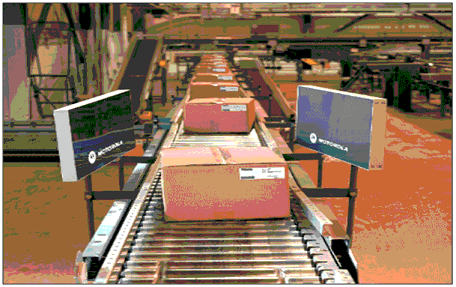

Robot pickers are one wellspring of mistakes and a key area where autonomous robots are pulling more than their weight. Incoming totes and cartons may contain RFID tags or bar codes that can be scanned immediately by scanners and then sorted and diverted to the appropriate location by robotic arms. The comprehensive automated warehouse system is multifold. Warehouse operators can rent additional robots to accommodate increased demand during peak season, returning them when demand returns to normal. Collaborative mobile robots do not require infrastructure changes, unlike conveyor systems, so they’re easier to implement.

Radio Frequency Identification (RFID) Technology

RFID’s technology captures digital data encoded in smart labels and tags through a reader via radio waves. This technology reduces total order cycle time order and errors made in deliveries of customers’ orders. Radio-frequency identification is replacing traditional labeling, storing, and finding products. These are digital tags placed on goods and packages that come into the warehouse and can replace the scannable barcodes, which take up a significant amount of time to attach and scan.

Radio waves can scan tags from afar. They are can automatically scan an area of the warehouse to detect where the digital tags are. Saving significant time and energy on identifying, finding, and pulling goods. RFID tags also can minimize inventory inaccuracies. The scanner warehouse can immediately detect how many products there are, rather than having to count boxes by hand, and also can determine if any products are located in the wrong area of the warehouse. This inventory control mostly an accurate system to date. A digital tag is attached to packages as they enter the warehouse. This speeds up the inventory pulling process. If everyone along warehouse RFID improve loading, unloading, and shipping by always knowing where individual inventory products are.

Warehouse Automation Guided Vehicle Technology

Automated Guided Vehicles (AGV) are enabling the optimization of space in warehouse facilities in manufacturing. AGV is the key focus in the warehouse and manufacturing sector for continuous growth and sustainability. Growth in e-commerce is the main driver for AGV demand in warehouse automation. Automated guided vehicles can carry out tasks such as palletizing, racking, and managing container storage. The technology could be used in warehouses to reduce the need for humans to operate vehicle systems. Inventors hope to use technology to create a more efficient way of transporting goods. Once a product is onboard an AGV, it is tracked so “lost” or misplaced product will be minimized. In a production environment with multiple operations conducted at varying times. AGVs also can assist in line balancing. AGV system’s costs are very predictable and while labor costs tend to increase. Can change quickly depending on local economic conditions. Collision avoidance capabilities prevent damage within the facility.

Warehouse Management System (WMS)

WMS helps to manage warehouse operations and enables organizations to develop their competitive edge. The system will minimize the labor charges and thereby improve customer services. WMS provides visibility to the real-time data and will show the status of the inventory. The WMS starts keeping a track of the material, goods, and products once it reaches the warehouse. WMS will track the item until it reaches the end customer. If it is returned by the customer, WMS will again start tracking, until it reaches another end customer. Hence, the functions of WMS include receiving goods, packing, dispatching goods, tracking the shipment, and updating its information and all these functions together can be called a warehouse operation.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Bryan Quek Guan Kia, DLSM. (2021). “Key Technology Systems to Implement Integrated Logistics”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-technology-systems-implement-integrated-logistics/, accessed 19/06/2021.

Goh Siang Wei, DLSM. (2020). “Technologies for Warehouse Automation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-warehouse-automation/, accessed 19/06/2021.

Marvin Edward, DLSM. (2019). “RFID Technology for Orthopaedic Warehousing and Distribution”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/rfid-technology-orthopaedic-warehousing-distribution/, accessed 19/06/2021.

Mohamed Farouk Bin Jailabdeen, ADLSM. (2021). “Digital Technologies for a Smart Warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technologies-smart-warehouse/, accessed 19/06/2021.

Steve Hitchings. (2019). “10 Benefits Of Choosing The Correct WMS | Kenco”. Retrieved from https://blog.kencogroup.com/benefits-of-choosing-the-correct-warehouse-management-system-software-wms-for-you, accessed 19/06/2021.

Yuliia llliv. (2020). “Implementation of IoT in Your Smart Warehouse”. Retrieved from

https://inveritasoft.com/blog/implementation-of-iot-in-your-smart-warehouse, accessed 19/06/2021.