Global sourcing refers to seeking goods and services beyond one’s borders, i.e., from the global market. It is a procurement strategy in which companies try to find the most cost-efficient place globally for manufacturing goods. According to purchasing and procurement professionals, companies should be able to source both inside and outside their national borders. They are then subsequently better able to compete. Most companies choose a global sourcing strategy because costs are lower abroad. Either labour costs or raw material costs are lower. Often, both raw material costs and wages are lower.

Table of Contents

Make or buy analysis

In some circumstances, it might make sense for a company to manufacture a product from sourced raw materials or components. In others, companies might find it more profitable to pay another company to perform the manufacturing process and then sell the finished product. The decision about whether to make or buy is not always an easy one. Companies must examine the following factors in order to make the most cost-effective choice:

• Cost

If the goods or services are to be produced in-house, companies must consider the costs associated with labour and other capital assets. In some cases, the capital assets might be better used in some other way. If a supplier will be manufacturing the product, companies must factor in the costs of dealing with the supplier and correcting any errors to ensure quality control.

• Supplier Reliability

Companies must be confident that a supplier will produce a regular supply of product and deliver it in a timely fashion. An interruption in supply of raw materials can be prohibitively expensive, because human resources and plant machinery will not be used for an indeterminate time. In order to ensure a constant supply of materials, companies can acquire the supplier company. The company can also hold an amount of safety stock. This involves paying additional inventory storage costs and potential obsolescence cost, but these might be justified if there are frequent interruptions in supply. The company can also select a supplier that is located close to the production plant to cut down on transportation times.

• Production Capacity and Competitive Advantage

If the company does not have adequate production capacity, it can choose to subcontract out some or all aspects of production. If a company does not want its competitors gaining knowledge about a proprietary product or process, it should not use external companies to produce its products.

Total acquisition cost (TAC) analysis

The price that a company will pay for goods or services will depend on various factors, such as the respective negotiating skills of the importer and the supplier; the quality of the materials or service provided; the available quantities of the product or availability of the service; as well as the distance goods or service personnel must travel.

Instead, companies must consider the total acquisition cost (TAC). This takes into account the costs involved with issues such as:

• transportation

• international trade documentation

• inventory

• supply chain interruptions

• import fees

• fixing poor quality supplies

• making required adjustments to foreign-produced goods

• reverse logistics of handling repaired or returned items

Supply-Base Rationalization and Consolidation

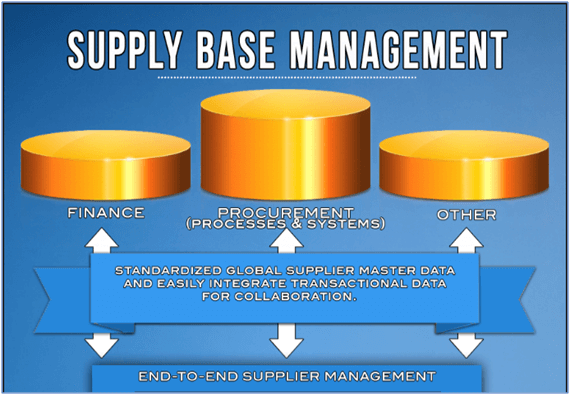

The more suppliers a company has, the more complex its supply chain becomes and the more expensive it is to manage. Companies must aim to ensure the supply of goods or services while minimizing the number of suppliers, maintaining quality standards and meeting cost objectives.

Companies can ensure the quality of supplies by insisting that suppliers implement quality-management systems, such as International Organization for Standardization (ISO), and raise quality standards. Higher standards of quality will automatically mean that some potential suppliers are not eligible for the supply chain, thus minimizing the number of suppliers.

With a smaller number of suppliers, companies must purchase more from each supplier and purchase more regularly. This will usually result in a reduced purchase price. Because each supply relationship takes time and effort to manage, fewer supplier relationships result in reduced costs. Working with fewer suppliers will make it easier for companies to implement processes aimed at improving the supply chain.

Primary and Secondary Sourcing

In some circumstances, a company will be able to, or will have to, use a sole source for their supplies. However, the company should always have a contingency plan in case a sole supplier becomes unreliable, is taken over by a competing company or is affected by external events. Many companies use primary and secondary sourcing, in which a primary source is used for as long as they meet company requirements for supply, delivery and quality, and a secondary supplier is available to cover shortfalls.

E-procurement

When a company wants to receive bids from several suppliers, online bid-based sourcing can be used to streamline the process. Importers can put an RFP/ RFQ on an online notice board and potential suppliers can post their response confidentially. This system reduces paperwork and speeds up the bidding process, especially when bidders are located overseas.

Challenges of Global Sourcing

The buyer and the seller must agree on a currency to use. While some buyers insist on their own currency for simplicity’s sake, prudent decisions consider use of the supplier’s currency when the buyer’s currency might strengthen relative to the supplier’s currency between the agreement and payment dates.

Lead time for global purchases is usually significantly longer than for domestic ones. This is due to ocean travel being slower than air travel and customs clearance adding time not involved in domestic sourcing. If you are unfamiliar with the supplier’s language and culture, you increase the risk of communication, misunderstandings, and offensive or uncomfortable encounters.

While domestic sourcing usually involves one shipping mode, global sourcing involves multi-modal transportation, which is a strategy for combining air, water, and ground transportation to get goods from the supplier to the port of the supplier’s country to your country’s port to your dock.

Finally, global sourcing often involves payment using a letter of credit which requires the involvement of both the buyer’s and supplier’s banks.

Conclusion

A good global sourcing strategy is often used to benefit from lower labour costs abroad. But there are also other additional costs for a buying organization to bear that are not part of domestic transactions. They include multi-modal freight charges, broker fees, bank fees, taxes called duties, and insurance to name a few. Global sourcing forces buyers and suppliers to choose one of three bodies of law to apply to their contract: the law of the buyer’s country, the law of the supplier’s country, or one applicable under a treaty accepted by both countries.

References

Charles Dominick. (2007). “What Should A Global Sourcing Strategy Address”. Retrieved from https://www.nextlevelpurchasing.com/articles/global-sourcing-strategy.php, accessed 01/09/2018.

Dave Henshall. (2015). “A Guide to Global Sourcing”. Retrieved from http://purchasingpractice.com/a-guide-to-global-sourcing-for-competitive-advantage, accessed 01/09/2018.

Ewan Roy.(2015). “5 methods to build a more efficient procurement strategy”.Retrieved from http://www.tradeready.ca/2015/fittskills-refresher/5-methods-build-efficient-procurement-strategy, accessed01/09/2018.

James Hudson. (2018).“How Can Global Sourcing Services Be Advantageous to Your Business?” Retrieved from https://medium.com/@jameshudson4356/how-can-global-sourcing-services-be-advantageous-to-your-business-8738bd7bd26c, accessed 01/09/2018.

Lau Chee Leng. (2018). “Eight Essential Steps for an Effective Global Sourcing Strategy”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/eight-essential-steps-effective-global-sourcing-strategy, accessed 01/09/2018.

MBN Market business news.(2018) ”Global sourcing – definition and meaning”. Retrieved from https://marketbusinessnews.com/financial-glossary/global-sourcing, accessed on 29/08/2018.

Wong Kok Wei. (2018) “Importance of Strategic Sourcing Skill for Effective Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/importance-strategic-sourcing-skill-effective-procurement, accessed 01/09/2018.