Logistics assume a gigantic job in the smooth activities of a business. In any case, at scale, it is amazingly hard to run an immaculate Logistics division because of the sheer number of factors and requests that such a logistics would be dependent upon.

Logistics can be thought of as the business work liable for “getting the correct thing in the correct amount at the opportune time at the perfect spot at the correct cost in the correct condition to the correct client.” Along these lines, it is basic that organizations put resources into their logistics divisions to guarantee the most extreme consumer loyalty and by and large profitability.

Table of Contents

Warehouse Management System (WMS)

The WMS is urgent considering the way that it helps control and oversees everyday activities in a warehouse. It additionally can give a strong establishment of the business to best practices for receiving, put-away, inventory management, order processing, replenishment, picking or packing, as well as loading and shipping.The warehouse management system can decrease the probability of blunders that could happen when an item is transported and help an organization satisfy arranges all the more quickly and promptly follow requested items inside the warehouse.

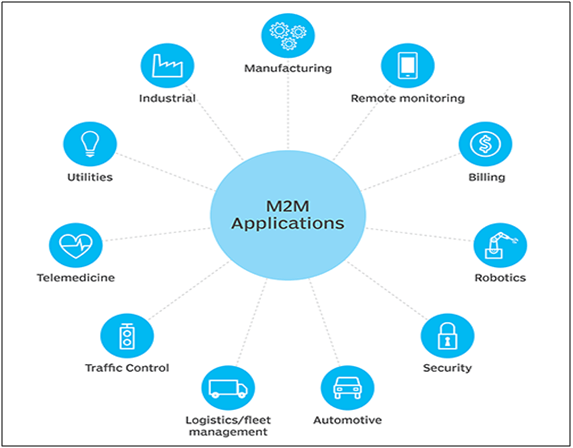

Machine-2-Machine Technology

In the course of the most recent couple of years, machine-to-machine innovation, or M2M, has enormously developed into an increasingly advanced system that helps screen and streamline all mechanization parts of warehouse operation. At the point when joined with warehouse management system (WMS), the latest M2M system is making it easier to control all hardware inside the warehouse that is essential to the request satisfaction process. This innovation helps gather and exchange data that furnishes warehouse manager with noteworthy data that can confirm operational strategies and speed up choices.

Order Fulfilment Technology

Each assignment spot ought to consider presenting the most recent requesting satisfaction improvement in the market. Particular dissemination place advancement game plans are open to help extend demand picking productivity and lift exactness.

There are 3 essential courses of action: Pick-by-Light; Put-by-Light; and Vision Picking. These advances help automate dissemination focus systems and offer an inexorably capable.

- Pick-by-Light System

These structures use specific light shows to direct warehouse assistant to items zones. They make it less awesome for a warehouse assistant to know which items to pick and how many amounts. These systems are altogether flexible and the progress goes with the ability to plan, control and separate volumes of orders picked.

- Put-by-Light System

This innovation guides warehouse assistant how and where to apportion items in a warehouse for orders. These systems are exceptionally proficient with regards to picking from mass stock. The innovation is perfect for the retail warehouse that manages clothing, outdoor supplies, individual consideration things, accommodation nourishments, goods and general products.

- Vision Picking System

Vision picking enables warehouse assistant with access to continuous computerized request data while liberating them totally from handheld RF gadgets. The brilliant glasses give visual and voice prompts to control warehouse assistant. The glasses likewise have route includes that can detect the warehouse assistant’s positioning in the warehouse.

There is a visual showcase of request data and target area that guarantees total error-free picking. This improves profitability, precision and prompts a quicker satisfaction rate. It consequently tracks parts and serial numbers continuously enhancing quality control. Picture catching guarantees the accuracy, so the warehouse assistant doesn’t have to make any extra steps.

Autonomous Robotic Technology

Autonomous portable robots additionally offer new open doors for stock checking. At the point when joined with RFID-labelled items and gear, these machines would now be able to direct conduct their stock count autonomously as plans controlled by the warehouse operator.

Individuals may regularly do stock counts every three months however, they would now be able to do it at regular intervals with continuous information to settle on better storage and layout decision about their facility. It does not just diminish the requirement for manual stock tallies yet in addition offers continuous mapping to managers can without much of a stretch picture item stock storage. A committed RFID following arrangement can persistently check stock tallies, spot and address issues or discrepancies before they become greater issues, just as quest for a particular tag if an item gets lost or lost to forestall pointless inquiries or expedited re-orders.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Adam Robinson, (2017). “7 innovative Warehouse Management Technologies to Adopt”. Retrieved from https://cerasis.com/warehouse-management, accessed 14/03/2020.

C.H. Robinson. (2019). “what is a transportation Management System (TMS)?”. Retrieved from https://www.freightquote.com/define/what-is-transportation-management-system-tms, accessed 15/03/2020.

Chan Thiam See, DLSM. (2019). “Essential Considerations for using a Global Logistics Service Provider”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-considerations-using-global-logistics-service-provider, accessed 14/03/2020.

Helmi Salleh, ADLSM. (2019). “Autonomous Devices for Digital Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/autonomous-devices-digital-warehousing, accessed 15/03/2020.

IWMSGGlobal. (2019). “Vision Picking can transform your Warehouse”. Retrieved from https://www.iwmsglobal.co.nz/blog/vision-picking, accessed 14/03/2020.

Markus Kückelhaus. (2019). “Unmanned Aerial Vehicles”. Retrieved from https://www.logistics.dhl/dk-en/home/insights-and-innovation/thought-leadership/trend-reports/unmanned-aerial-vehicles.html, accessed 15/03/2020.