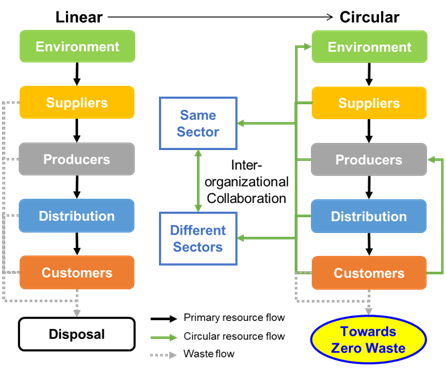

Resource constraints and environmental pollution resulting in global warming are driving the transformation of world economy from that of linear “take-make-dispose” which consumes and transforms raw materials into products that are used until they are eventually discarded as waste, to a circular “make-use-recycle” model which purports to eliminate waste and ensure sustainability.

Circular supply chain (CSC), a supply chain loop that integrates zero-waste approaches through innovative supply chain management has thus become increasingly important to support the economic transformation. The objective of this article is to develop a holistic view about the critical enablers supporting the transformation from the traditional linear supply chain to CSC.

Table of Contents

CSC and The Critical Enablers

CSC encompasses a forward supply chain which material and information flow linearly from suppliers, producers, distribution and to customers, and reverse processes such as the collection of discarded products, reverse logistics, quality assessment and 6Rs (Recover, Reuse, Remanufacture, Recycle, Redesign and Reduce) for material circulation and value extraction. Unlike the traditional linear supply chain which is typically a straightforward line-like network, the CSC tends to be a dynamic and hyper-connected network. All the stakeholders in the CSC within the same and/or different value chains are reciprocally connected and interdependent in terms of knowledge exchange and collaboration for a common strategic intent of eliminating waste and improving sustainability performance.

The three critical enablers for companies striving to loop their supply chains to improve their economic and social standings and environmental sustainability are Industrial Symbiosis (IS), Circular Procurement (CP) and Circular Metrics (CM), and Digital Technologies (DT).

Industrial Symbiosis (IS)

Industrial Symbiosis is a collaborative strategy to achieve zero-waste. It enables the by-products/ wastes of one company/ sector to be consumed or reused by other companies/ sectors. IS in Norrköping, Sweden, as shown in the diagram below is a good example of a symbiotic network that synergistically integrates industrial, urban and agricultural activities towards improving sustainability. There, the IS network provides a conducive ecosystem for cross-industry collaborations and synergies in terms of resource sharing and waste elimination. As a result, companies located in the city can achieve economic benefits by way of reduction of costs associated with environmental protection taxes, waste disposal and input purchasing, while reducing carbon emissions, spurring innovation and facilitating new cross-sector partnerships.

Generically, IS can be developed in three stages:

(1) Identify and evaluate opportunity: Through information exchange, companies can identify the relationships between inputs and outputs required/ produced in different organizations and evaluate the commercial, political, social, environmental, financial and technical viabilities of the identified IS opportunities. Collaboratively, new processes can be developed to transform the by-product/ waste into a usable resource.

(2) Overcome challenges: When implementing business opportunities based on IS exchanges, it is crucial to discover the key determining factors of IS and the challenges companies encounter. Trust and transparency form the cornerstone for inter-organizational alignment on sustainability objectives and collaboration ensuring successful commercialization of IS opportunities.

(3) Review and feedback: With regular progress review, companies can learn and establish a common knowledge database on successful IS exchanges and processes. Furthermore, adopting a feedback culture and adaptive management help to continuously improve the IS processes and strengthen cross-industrial collaboration and partnership.

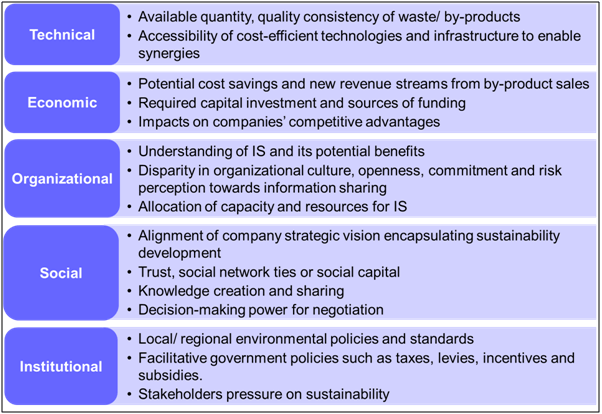

During the development of IS, it is crucial to identify the key determining factors affecting the evolution of IS network. The below diagram sets out the key determining factors entailing technical, economic, organizational, social and institutional aspects for IS initiatives.

Among them, technical and economic factors are typically deemed to be the most essential fundamental requirements. Organizational, social and institutional factors could also be important factors depending on the nature and type of the industry involved and geopolitical context.

Circular Procurement (CP) and Circular Metrics (CM)

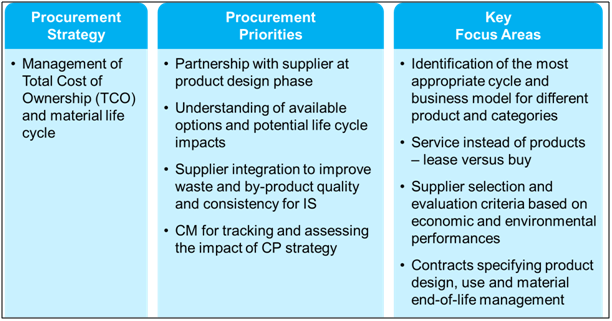

CP is an essential lever for CSC to extend product life cycle by improving product safety, durability, reliability and reusability, enhance resource recovery and minimize product wastage while delivering financial benefits. It can be defined as the procurement of quality products or services at competitive prices that contribute to loop the material and product supply chains, thereby eliminating waste generation and negative socio-environmental impacts across the entire product life cycle. The diagram below summarizes the implications of CSC management for procurement.

The three key levers for executing CP:

(1) System lever allows the procurement function to incorporate circular approaches through differentiated contractual arrangements. For instance, the supplier take-back agreement specifies for the return of end-of-life products to the supplier for reuse, remanufacture or recycle, while a product-service agreement allows the supplier to sell the services the product provides but retain the product ownership based on pay-per-use model.

Illustratively, the jet engines made by Rolls-Royce for British Airways are not purchased but leased to British Airways while Rolls-Royce retains the responsibility for all installation, maintenance, and reclamation processes on the jet engines, thus eliminating the potential disposal of engines in landfill.

(2) Supplier lever emphasizes the suppliers’ capability in building circularity into their own systems and processes to ensure the products and services offered conform to CSC requirements. Procurers can establish supplier selection and evaluation criteria based on suppliers’ economic and environmental performances.

(3) Product lever helps procurers identify the composition of the products, trace the material provenance, analyse the resource efficiency and content of recycled materials, and recyclability of end product after dismantling. Through product lever, procurers can better manage the TCO and material life cycle.

As CP plays a pivotal role in ensuring circular production and reuse of products/ services, adopting a common approach to measuring and monitoring the performance of CP in line with CSC management is essential. CM as illustrated in the diagram below, provide a standard methodology for companies to measure circularity performance and monitor the progress on circular transition.

Digital Technologies (DT)

DT facilitate transition towards a CSC through enhancing connectivity and timely sharing of information across the manufacturing, distribution and consumer ecosystems during the products’ use phase and at their end-of-life phase. Furthermore, the enhanced traceability and reliability of transactions via DT increase consumers’ awareness and ability to make sustainable choices.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Chirag, P. et al. (2019). “McKinsey: Artificial intelligence and the circular economy: AI as a tool to accelerate the transition”. Retrieved from https://issuu.com/fredzimny/docs/artificial-intelligence-and-the-cir, accessed 12/11/2019.

Farooque, M. et al. (2019). “Circular Supply Chain Management: A Definition and Structured Literature Review”, Journal of Cleaner Production, 228, 882-900.

ICLEI. (2017). “Public Procurement for A Circular Economy: Good Practice and Guidance”. Retrieved from https://ec.europa.eu/environment/gpp/pdf/Public_procurement_circular_economy_brochure.pdf, accessed 01/11/2019.

Manavalan, E. and Jayakrisha, K. (2019). “An Analysis on Sustainable Supply Chain for Circular Economy”, Procedia Manufacturing, 33, 477-484.

Melissa J. Rusinek. (2018). “Blockchain for a Traceable, Circular Textile Supply Chain: A Requirements Approach”. Retrieved from http://asq.org/software-quality/2018/12/supplier-quality/blockchain-for-a-traceable-circular-textile-supply-chain-a-requirements-approach.pdf, accessed 11/11/2019.

Prosman, E. J. (2018). “Supply Chain Capabilities for Industrial Symbiosis: Lessons from The Cement Industry”. Retrieved from https://doi.org/10.5278/vbn.phd.eng.00063, accessed 02/12/2019.

Sunny Chaudhary, DPSM. (2019). “Key Considerations for Reverse Logistics of Agricultural Products”. Retrieved from SIPMM: https://sipmm.edu.sg/key-considerations-reverse-logistics-agricultural-products/, accessed 01/12/2019.

Theresa Pang Kim Lian, DLSM. (2019). “Key Considerations for Reverse Logistics Operations”. Retrieved from SIPMM: https://sipmm.edu.sg/key-considerations-reverse-logistics-operations/, accessed 01/12/2019.