Special inventory in warehouse environment are guided by policies, federal laws and compliances that are set up by organizations. In warehousing contracts, special inventory imposed by a government body are Central Narcotics Bureau (CNB), and Immigration and Checkpoint Authority (ICA). Private associations such as Round table on Sustainable Palm Oil (RSPO), Convention on International Trade in Endangered Species of Wild Fauna Flora (CITES) are some of the examples that determined to be regulated under special inventory.

Also, any organization can classify Inventories as special due to it requires to be treated with special requirement compare with the rest due to safety, quality, value & some others factors that been determined by own organization. Special inventory is also to be audited regularly to ensure that each individual department follows the protocol. In good warehousing practices, special inventories are handled with care from the initial stage to the ending stage.

Table of Contents

Receiving Operation for Special Inventory

Receiving area is the most active area filled with activities most of the time. Any potential bottleneck caused in that area, might have a bad impact towards the operation work flow. Applying a standard turn for each transporter to enter the loading dock, may reduce congestion. It might be time consuming, but it gives the advantage for the receiver to clear the receiving area before the next transporter comes in. It can also reduce the chance of mistake during receiving as the checker would not be made to rush while checking all the incoming stocks. The following steps and procedures are performed by Central Receiving staff. In warehouse operation receive various cargo with multiple batches and different quantity in daily basis. The major task for receiving is receive the material and store with accuracy. The receiving person must be well trained to read the document and physical label to identify hazards and way of handing the material. For the special inventory items that’s must be attached an additional document and labels on the physical such endorsement certificate by the organization. Also, with simple excel administration can be identifying the special item upon receive inbound warehouse. The best practices once identify the special inventory is follow the ILVT steps for eliminate error in operation at receiving stage.

Storage of Special Inventory

Special inventory storage can vary depending on protocol set by organization. Usually special inventory item is kept in specially designated storage unit or in a special storage method. For the better management on the storage of special inventory , register as few as possible responsible individuals to handle the material. In good warehousing practice staff need to be well trained and follow all protocols subjected to special inventory.

• Storage of DEA control substance: Must be a cage storage or lockbox. It should be two doors and two locks (each lock is keyed differently). The key must be kept by supervisors and above who will implement log book system.

• Acetaldehyde substance: Must be stored in low temperature-control environment given its low flash point and should be kept in a separate cabinet or secondary container in a well-ventilated place, always away from potential source of ignition.

• Allergens Storage: Where allergenic raw materials are de-bagged or de-boxed, they should, if possible, be placed in dedicated lidded and labelled containers and made easily identifiable. Such containers should not be used for storage of any other raw materials.

Picking and Packing of Special Inventory

Picking or order process and packing is one of the warehousing processes.It consists in taking and collecting articles in a specified quantity before shipment to satisfy customers’ orders. It is a basic warehousing process and has an important influence on supply chain’s productivity. Warehouse efficiency will also improve when items are assigned to the correct storage media. Picking is the process of pulling inventory from the warehouse to be included in the customer order.

Packing is the process of gathering and packaging these items to prepare them for shipment to the customer. Picking with correct quantity and batch is a very important practice for special inventory because wrong picking can have a direct impact on inventory accuracy thus affects company reputation when being audited.

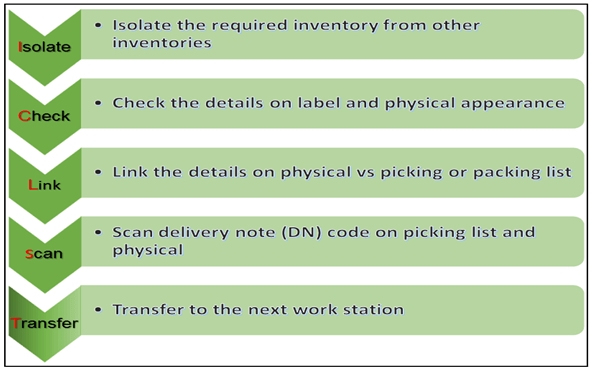

On top of that selecting the correct packaging and product identification, with necessary remark label is important to our end customer to provide the information needed for the special inventory material. To reduce the cross shipment, picking and packing should be done by different persons. There are many methods and practices on picking in warehousing contact. ICLST process is more likely to be more effective in reducing human error during picking and packing process.

Special Inventory Accuracy and Disposal

For special inventory, we may need to establish schedule to conduct cycle count.Week, or monthly basis according to organization protocol on a rotating schedule.In most industry, keeping track of materials are never an easy task. Therefore, implementing daily cycle counting is a must in keeping track of inventory movement in and out from store as to avoid disruption to the operation and increase inventory accuracy. It allows to detect mistake in real time and proceed with adjustment accordingly when there is inventory discrepancy. Daily counting will also benefit accuracy records by having decreases opportunities of errors. If a discrepancy on special inventory item, there should be an immediate investigation taken and need to be reported to the superior or management pertain on the inventory discrepancy. Also need to prepare formal report according to guideline and protocol that been set by organization in declaring any discrepancy. Immediate system adjustment must be made on the discrepancy upon getting the approval from the management.

Another aspect that we need to understand of the special inventory is that all approved disposal need to be undertaken by accredited disposal company who will engage the disposal and issue certificate of disposal. This will then be file up and shown as a proof that special inventory been destroyed according to the guideline.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Cathrine Pang Siu Wen, DLSM. (2019). “Key considerations for warehouse storage”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-warehouse-storage/, accessed 21/12/2019.

Cyrus Leong King Fatt, DLSM. (2019). “Integrated Logistic practices for the Food Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/integrated-logistics-practices-food-industry/, accessed 21/12/2019.

Sazali Salleh, PDWM. (2019). “5 best practices for an effective warehouse”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-best-practices-effective-warehouse/,accessed 17/12/2019.

Syed Muhamad Faizal, DLSM. (2017). “The Five Essential Methods for an Effective Warehouse Operation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-essential-methods-efficient-warehouse-operation/, accessed 21/12/2019.

Thomas P.Dinapoli. (2018). “Reeving Best Practices”. Retrieve from https://www.osc.state.ny.us/agencies/outreach/fallconfer2018/presentations/2018_bse_receiving_best_practices_final.pdf, accessed 17/12/2019.