As competition intensifies in the fast-moving-consumer-goods (FMCG) sector, procurement department plays a critical role to manage order planning with budget allocation, budget planning and cost savings, and to ensure delivery on time. The best procurement practices are designed to be cost-effective and improve productivity, which also applies to a company.

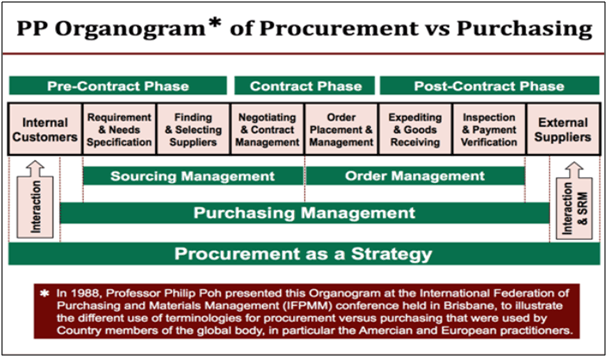

This article attempts to examine the best practices for procurement in the FMCG sector. But first, let us differentiate the terminologies of procurement and purchasing. Purchasing covers the system and processes from sourcing to order management. Procurement involves the strategic implementation of Purchasing, active interaction with both internal customers and the external suppliers, through Supplier Relationship Management (SRM). The chart below illustrates the difference between Procurement and Purchasing.

Table of Contents

Aligning the Procurement Functions

Procurement is being recognized as a strategic function that can deliver bottom-line savings. Some organizations would opt for centralized procurement while some prefer the decentralized approach with procurement professionals present in each department. However, some may choose a combination of these two options. But the right structure needs to be followed up by procurement professionals.

Procurement professionals running the procurement process need to have excellent supply chain management skills and knowledge. In order to advance further, they are also needed to focus on strong communication and relationship building skills, strategic thinking and a value-focused approach. As with any business decision, the staffing process for a company’s procurement unit should be done with a view to improving the effectiveness and efficiency of business processes. Some companies prefer to place their procurement professionals across every business unit, while others take a more centralized approach by placing all procurement professionals together in one department.

There are also those who adopt both methods by using a centralized approach when planning procurement process strategies and designing procurement policies to obtain consensus, and then opting for the decentralized approach for better implementation and service improvement.

Allying with Key Suppliers

Supplier relationship management goes beyond inking the deal after both parties have agreed to the procurement policies and are clear on the procurement processes that will be put in place. Through effective two-way communication, both suppliers and the organizations will work together to strengthen the relationship and is essential to influence the quality of contract performance. Alliance management also ensures that the lines of communication are clear, and any problems that arise can be resolved efficiently and effectively.

The foundations that are needed to form a strong working relationship with suppliers are Respect; Trust; Mutual benefit; Fairness; and Honesty. A good partnership with suppliers can strengthen an organization’s business. The suppliers will also want to build strong partnerships because that builds a strong business for them too. The selection, cultivation, and building up supplier relationships should be a continuous process that strives to balance the organization’s business needs.

The Company can select a variety of vendors offering different rates and services along with the product to come up with the right mix of the best product prices and services. This allows the company to become more independent of suppliers but can still rely on other vendors in case of issues with one of them.

Creating Collaborative Strategic Sourcing

Strategic sourcing plays an important role in the cost structure and the main objective is to improve the acquisition process, supplier performance and minimizing risk. The collaborative approach involves internal customers in the process of decisions making. Communicate the procurement objectives, strategies and feedback channels, which can lead to lower costs, more efficient processes and better responsiveness to customer needs. Another involvement is analyzing high-volume purchase and developing long-term partnerships with a select group of suppliers that can provide quality products and services at low costs.

This strategy is available to provide supplies that meet the needs of the whole organization. It is necessary to speak to the members of each business unit to understand their main objectives and strategies and obtain their views and feedback on sourcing the right supplies. This procurement approach is cost-effective and ensures a steady supply of products which also streamlines business processes and shows that the procurement unit is attuned to evolving business needs. Sourcing agencies can invest in e-sourcing technologies to identify leakages in sourcing projects. Using the supply base as a resource can significantly increase efficiency and reduce cost.

Establishing Control Levels and Minimizing Risk

Every business process should be structured and follow a set of policies and procedures. This also applies to supply chain management. With the policies and procedures in place, there is also a need to review them periodically to ensure that they are still relevant and not creating issues in the supply chain. Keep policies and procedures simple and easy to understand will ensure compliance and streamlining them help put in place controls while deterring theft, fraud and other issues that could pose risks.

Policies and procedures for procurement need to be well-structured. Both must be realistic, easy to understand; and reviewed and updated regularly to remain relevant and effective. There should be no bottlenecks and should have a smooth-running process with the right controls to mitigate risks.

Risk mitigation is an important aspect of procurement that forms a part of the policies and controls. The important aspects here are to identify all risks, determine the probability of a risk, assess the impact of risk on the procurement activities and prioritize prevention and monitoring. Risk management may also involve developing alternative sources in case of natural disasters or financial problems which can cause disruptions in the supply chain.

Selecting the Right Technology

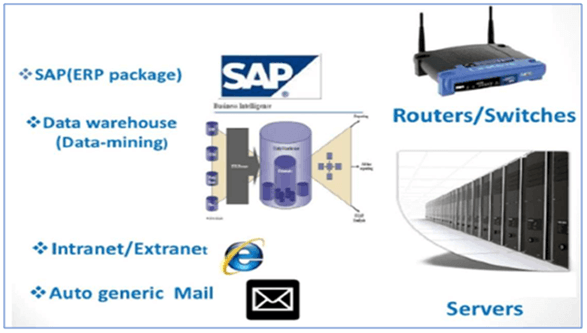

Companies must understand that not all the procurement software will automatically improve efficiency but requires to be assessed by the current process first. This is to understand where improvement is needed and then by selecting the right software to meets the requirement. The right system will allow data to be taken in and meaningful information to be retrieved. With the volume and availability of data, new technology makes it easy to track decision-making processes. Furthermore, Historical data can be used to create benchmarks for future performance as well. With the help of technology, procurement agility can be increased and provide value to the organizations.

Subsequently, it will be easier to know which software or technology can best meet the needs of those processes. This is cost-effective and efficient compared to structuring your workflows and processes around technology. The suitable technology for your organizations allows you to extract the necessary data and valuable information quickly and easily, which is imperative for making sound business decisions.

Conclusion

A procurement strategy will help organization success and maximize value contribution. Best procurement practices have become necessary to succeed where the right methods, processes, and philosophies can turn the organization around. Fast-moving-consumer-goods (FMCG) sector needs to go through the above-mentioned transformation then improvement, but these practices do give an organization to check the effectiveness of a procurement function and efforts to improve. The organization has the responsibility to take necessary action to implement procurement best practices and make it successful and it allows procurement professionals to perform better and meet the objectives.

Importance of Strategic Sourcing in Procurement

References

Fabian Lee. (2017). “Effective Procurement Practices for Mass Consumption Products”. Retrieved from https://publication.sipmm.edu.sg/effective-procurement-practices-for-mass-consumption-products/, accessed 20/06/2019.

Marc Wins. (2018). “5 steps to a successful strategic procurement process”. Retrieved from https://www.procurement-academy.com/5-steps-to-a-successful-strategic-procurement-process/, accessed 20/06/2019.

Shruti Agrawal. (2016). “Six Key Steps to Sustainable Procurement Success”. Retrieved from https://www.scmr.com/article/six_key_steps_to_sustainable_procurement_success, accessed 20/06/2019.

Tashya Viknesh. (2017). “10 Procurement Best Practices You Should Be Doing Right Now”. Retrieved from https://blog.thunderquote.com/2017/06/02/10-procurement-best-practices-you-should-be-doing-right-now/ accessed 20/06/2019.

Vivien Cheah. (2018).“Six Procurement Best Practices for the Construction Industry”. Retrieved from https://publication.sipmm.edu.sg/six-procurement-best-practices-construction-industry/, accessed 20/06/2019.