Dangerous goods are substance or articles which can pose a threat to people, property and/or the environment. When people travel, the mode of transport chosen is of great importance.

Vehicles, trains, boats, planes: each means of transport has its own characteristics that influence movement in terms of quality, comfort and duration. Similarly, when transporting dangerous goods, the mode of transport has a significant impact. Mechanical stress, humidity, pressure and many other factors can vary from one mode to another.

Table of Contents

Compliance with Regulations

For transportation of dangerous goods is highly regulated process as there are human lives and property involved at all stages of transport and in all mode. These differences are expressed through different regulations, and the current regulations for the transport of dangerous goods are divided into five categories:

• For transport by land, ADR regulations (European Agreement concerning the International Carriage of Dangerous Goods by Road)

• For rail transport, RID regulations apply (Regulations concerning the International Carriage of Dangerous Goods by Rail)

• For transport by inland waterway, ADN (International Agreement for the Transport of Dangerous Goods by Inland Waterway)

• The IMDG code (International Maritime Dangerous Goods Code) is applicable for transport by sea

• ICAO/IATA regulations (International Civil Aviation Organization / International Air Transport Association) are in force for transport by air

These are published in the UN ‘Recommendations on the Transport of Dangerous Goods’, known as the ‘Model Regulations’ because the document provides a framework of rules for the safe transport of dangerous goods by all modes – air, road and rail as well as sea. The UN Model Regulations provide a uniform set of safety procedures covering consignment and transport issues such as classification, identification, packing, marking and labelling, documentation, security and training.

Dangerous Goods Packaging and Protocols

We must first ensure that we pack the cargo adequately with the appropriate packing materials. Also, ensure the proper cushioning and lashing of the cargo so that it does not move inside the container and cause any leakage or damage. Hazardous goods should generally be packed in areas where it is quickly and easily accessible in case there are any emergencies. Often, DG is packed close to container doors so it can be thrown out or swiftly discarded in the event of an emergency to save the other cargoes.

Packaging need to be properly secure accordingly e.g. palletize, crating, temperature control package etc. Labelling of hazard labels need to be pasted on the final outer packaging to indicate internal substance. Marking of handling labels is a must for transporter to have proper knowledge of the cargoes

Identifying Dangerous Goods

All dangerous goods are uniquely identified for transport using a number and name allocated by the United Nations (UN Number and ‘Proper Shipping Name’ or PSN). For example, Kerosene is classified as a flammable liquid (class 3); ‘Kerosene’ is a recognised PSN; the UN Number for it is UN 1223. The UN number and PSN facilitate rapid and precise identification during transport to ensure correct handling, stowage, segregation etc., and appropriate actions in an emergency.

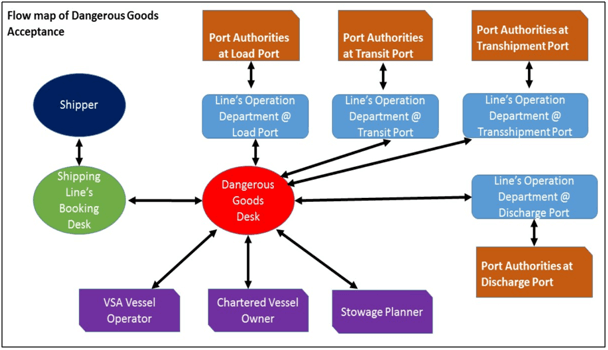

Documentations and Flow

Involved in the shipment of hazardous goods like SDS, DG request, DG packing list/Declaration, DG Manifest, TREM card and many more depending on the nature of the goods, country of shipment, receipt and mode of transport. As mentioned above, there are several hazardous classes and each of them has its own nature of hazard, segregation methods and handling requirements. These details can only be conveyed thru proper documentation to the people who do the transport movements.

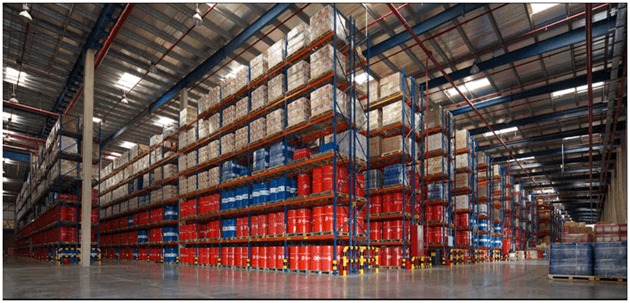

Storage of Hazardous Chemicals

Storage of dangerous goods to be complied with each country regulations as different countries have their own requirements. Safety data sheet (SDS) or labels need to check accordingly and follow any storage recommendations as some chemicals have temperature control requirement. Secure the chemicals against unauthorised access or use as some is under controls drug need to store separately. Keep minimal amounts of chemicals onsite and ensure that all chemicals are clearly, correctly, intact and legible labelled. The hazard classification and regulatory information risks in using and storing the product information about the components of the product emergency procedures.

Risk Assessment

A Risk Assessment will determine the level of risk and the controls required for the safe storage and handling of dangerous goods at your site. A risk assessment can be substituted by closely following a recognised industry standard or code of practice. Risk assessments should be conducted by a competent person with a knowledge of the work processes involving the chemicals consultation with people at the workplace reference to past incidents and industry knowledge the relevant Health and Safety legislation codes of practice interpreting the contents of the SDS.

• Do not allow chemicals to be exposed to the sun, excessive heat or sources of ignition

• Provide adequate ventilation

• Label shelves and cupboards so that chemicals can be stored in the right place

• Use placarding where required

• Use a solid wooden pallet for goods to be safely put on rack

• Label storage areas with DG hazard labels; separate them from each other

• Ensure waste is removed and disposed of appropriately

• Clear aisles and exits of equipment and packaging

• Tidy stock/storage rooms; treating them like they’re visible office areas

• Ensure exits are clear in case of an emergency or evacuation

Safety implementations

Ensure clear segregation schemes are maintained. Substance must be separated when being stored to ensure that incompatible chemicals do not mix if a spill occur. Do not store liquids above solids to avoid contamination in the event of leak. Always store corrosives on spill trays, never store flammable liquids in refrigerators or freezers unless they have been modified e.g. spark-proofed. Separate incompatible chemicals that could react dangerously if stored together and keep the outside of containers clean and the storage area tidy ensure shelves are not overloaded as well.

• Do not purchase these compounds in quantities greater than can be used in the specified storage time period.

• Label containers with receiving, opening and disposal dates.

• Ethers should be stored in the dark and under nitrogen if possible.

• Always check for the presence of peroxides before distilling any peroxide-former.

• Consult safety references (e.g. SDS) before working with peroxidizable compounds.

• If old containers of peroxide-forming chemicals are found, do not move them. Contact the Office of Health and Safety for assistance in disposing of the container.

Conclusion

As you can see from the above details, the shipping of dangerous goods cargoes is highly specialized and there are various aspects to be considered and addressed. Each entity in the chain needs to have the full awareness of the hazardous materials that are being shipped, the documentations, labelling, transport and regulations requirements to be followed. Similar as storage need to follow strict regulations of each countries as it involved the safety of people working and environment. Dangerous goods is not everyone’s cup of tea so strict regulations need to be followed and a high level of planning. Therefore, it is always better to appoint a Logistics Service Provider or hired a hazardous goods specialist who know the process, procedures, packing, packaging and documentation requirements to shipped and storing.

References

CourseHero. (2019).“Conclusions logistics systems and transportation”. Retrieved from https://www.coursehero.com/file/p52r1fq/Conclusions-Logistics-systems-and-transportation-consist-of-interdependent,accessed 11/12/2019.

David Moore. (2019). “Seamless Transport for A Sustainable Future”. Retrieved from https://heraldspace.com/2019/08/29/intermodal-freight-transportation-seamless-transport-for-a-sustainable-future, accessed 11/12/2019.

Mohamed Hardi bin Abdullah, GDLM. (2019). “Autonomous Trucking in Logistics Transportation” Retrieved from SIPMM: https://publication.sipmm.edu.sg/autonomous-trucking-in-logistics-transportation, accessed 11/12/2019.

MukeshKhadka. (2011). “BusinessIntelligence for Transportation and Infrastructure Systems”. Retrieved from https://www.westernite.org/annualmeetings/15_Las_Vegas/Papers/7B-Paz-Cruz.pdf, accessed 11/12/2019.

Sonia Lai Jie Yin, DLSM. (2019). “Key Success Factors for Effective Logistics Practices” Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-success-factors-effective-logistics-practices, accessed 11/12/2019.