As the global supply chain expands, warehouses are under constant pressure to perform better, faster and more efficiently. The challenge of lean warehouse becomes important as the amount of pressure increases. However, since lean is a relatively new concept in the warehousing industry, many warehouses may not be familiar with it. The aim of lean warehousing is to reduce waste and costs by constantly improving operational efficiency. This article discusses the crucial factors for implementing lean warehousing.

Table of Contents

Involvement in Lean Program

One contribution factor for the success of lean implementation is an excellent leadership and management. The engagement and commitment would increase employees willingness to participate in lean implementation.

Some organizations tried to implement lean but failed due to a lack of management support. As a result, manhood and leadership play a prominent part. The assistance of management is more than just terms. It entails allowing workers to develop and demonstrate their abilities and skills. Both directive and supportive leaders will achieve a positive outcomes by providing support from management to employees.

To better understand how the implementation of this process would affect the activities of other departments, it is important to establish a cross-functional team. For instance, one team produces processes that inflict damage on other team workflow. Involve key members of each team to get a sense of how this process will affect their work.

Lean Organization Structure

An organization’s structure relates to how people and teams interact. Individual activities must be coordinated and handled in order to fulfill the goals and objectives of the organization. Since it outlines reporting relationships, creates hierarchical communication networks, and describes how individual activities are connected together, structure is an essential tool for achieving teamwork. Organizations may operate under a variety of systems, each with their own set of benefits and drawbacks. Although any structure that is not well-managed will have problems, some organizational models are better suited to specific environments and tasks. With organization chart in place, employees will better understand individual responsibility, organize workflow and ensure important tasks are completed on time.

Lean Training Program

The involvement in human resource is another imperative factor for successful of lean. By training and empowering human resource, the organization can explore the ability to succeed in lean implementation. Human resource empowerment refers to increasing human resource knowledge, skills and motivation for achieve to organizational goals. Employees play an important role in providing valued service to customers because of the high level of customer contact in services. The organization’s highly skilled labors are critical to the company’s growth and success. As a result, in order to achieve the goal of lean implementation, the service provider must focus more on employee skills and training.

Improving Lean Processes with Technology

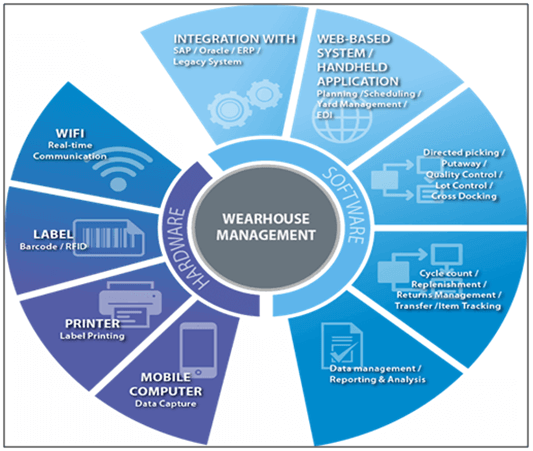

Technology has advanced and it has had a significant influence on society and the surroundings in a number of ways. Employing tools such as technology can help organization establish an efficient and stable system. Technology and other methods can assist organizations in developing an effective and reliable infrastructure. Technology comes in handy when it comes to analyzing data from lean assessment tools.A warehouse management system (WMS) is a software solution that provides inventory visibility and manages supply chain fulfillment operations from the distribution center to the store shelf.

Effective Communication during Lean Implementation

Another important aspect of lean implementation is communication. It stressed the importance of effective and regular communication in providing employees with a roadmap and keeping the momentum going in the implementation of lean toward continuous improvement efforts. In order to provide employees with clear goals and coherent mission statements, lean requires efficient top-down communication. Effective communication avoids confusion, provides purpose, builds a positive company culture and create accountability. This involves ongoing communication, gathering of feedbacks and questions from employees, and explaining why lean means change for the better.

Picking Technology for Lean Warehousing

Picking process is often regarded as the most time-consuming activity in a warehouse. Within a warehouse, up to 55 percent of operating costs are created. Since order picking has such a direct effect on customer satisfaction, it is critical for warehouse staff to make it as fast and reliable as possible.

An order should only be touched once during the picking and packing process in an ideal situation. To do this, the warehouse staff should ensure the order must be error-free and packed correctly the first time, moving from shelf to box to truck without having to be moved in and out of totes or repacked into containers.

When automation elements are incorporated into the flow, warehouses may benefit from near-perfect picking speeds. Robotic order picking, pick-to-light, and voice automatic picking are some of the automated picking tools that can be used to improve the picking process.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Dave Blanchard, (2013). “Top 5 Warehouse Challenges and How to Overcome Them”. Retrieved from https://www.industryweek.com/supply-chain/warehousing-and-distribution/article/21965137/supply-chain-logistics-top-5-warehouse-challenges-and-how-to-overcome-them, accessed 17/03/2020.

Hector Sunol, (2020). “Lean Warehouse Management and Why You Need It”. Retrieved from https://articles.cyzerg.com/lean-warehouse-management-and-why-you-need-it, accessed 17/03/2020.

Krishna, (2020). “A Guide to Lean Warehousing And Its Implementation”. Retrieved from Orderive: https://www.orderhive.com/knowledge-center/lean-warehousing, accessed 19/03/2020.

Lim Jun He, DLSM. (2019). Key Factor for Effective Warehouse Stoage”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-factors-effective-warehouse-storage/, accessed 17/03/2020.

T.Netland, (2015). “Five critical success Factors for implementing lean programs”. Retrieved from https://better-operations.com/2015/11/23/5-critical-success-factors-for-implementing-lean-programs/, accessed 17/03/2020.

Winnie Teh Cheng Hoon, DLSM. (2020). “Evaluating Lean Performance for Reverse Logistics”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/evaluating-lean-performance-reverse-logistics/, accessed 17/03/2020.

Wong Zhi Wei, DLSM. (2019), “Key Considerations for Warehouse Design and Layout”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-warehouse-design-layout/, accessed 17/03/2020.