Supply chains have become substantially more complicated as a result of globalization, involving multiple competitors from all over the world and a great deal of coordination. Companies optimizing digital technologies will have a huge impact on the whole supply chain process from the supplier to end customer. The fast moving consumer goods (FMCG) sector is often the early adopters of new technology in order to stay ahead of the competition. This article discusses how supply chains can be optimized with digital technologies.

Table of Contents

Data Analytics

Analyzing useful data can provide better understanding and management of customer needs and demands. There are basically four types of analytics, and businesses can gain a deeper insight into their customers’ requirements and the dynamic market trend. Descriptive analytics review past sales, inventory, customers, and stakeholders to provide insight into the past: what has happened to the change in customer buying behavior? Diagnostics analytics dive into data to understand: why did it happen? Predictive analytics uses the findings from descriptive and diagnostic analytics with statistical models to forecast: what will happen? Prescriptive analytics generate solutions based on algorithms on how to avoid a potential problem or optimizing on a promising trend. FMCG companies could input information into forecasting software on a routine basis to accurately anticipate customers behavior. As a result, optimal amount of stocks are keep on hand based on statistical forecast and there is low risk of inventory level running low.

Robotic Process Automation (RPA)

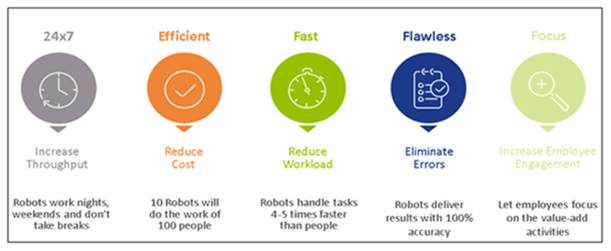

RPA automates business process by configuring software or “robot” to interpret applications for processing a transaction, data, response, and communication. The three main types of RPA are “probots” for processing data and information, “knowbots” for data collection and storage, and “chatbots” that acts as virtual agents answering customer queries online. The key benefits of using RPA in FMCG retail are useful sales analytics, new product Introductions, in-store planning, as well as order and returns processing. Automated analytics allows for quick access to reports that provide real-time information, which aids in the study of sales opportunities. RPA connects relevant stakeholders by automating processes and monitoring customers interest in real-time. Retailers can construct extensive and fact-based analyses of goods choices on a store-by-store basis using the data to anticipate customer expectations. RPA automates orders and returns, reducing delays in the processing of these activities, resulting in greater time for retails to manage exceptions.

Blockchain Technology

There are multiple layers, stages, and geographic locations in FMCG supply chain which relies on a decentralized database. Blockchain provides end-to-end traceability, from the raw material origin to the finished good. In addition, product manufacturing date, where is it produce, and nutritional content are stored in the blockchain, giving stakeholders greater visibility across all supply chain activities. Companies are also tapping on blockchain for sustainable materials traceability. This means that supplier’s claims of being using sustainable materials and reducing their environmental impacts can be counter-checked and verified. Customers can get latest information from the blockchain simply by scanning the QR code. In the event of product recall, customers or retailers will receive notification and actions can be taken promptly. Counterfeit products pose potential health threats to customer and loss of revenue to businesses. Blockchain provides a tamper proof chain of custody information, giving customers the transparency and authentication they need. Information is recorded and shared by numerous entities, therefore in the event of equipment failure, information remains intact, posing limited or no disruption to FMCG supply chain.

Artificial Intelligence (AI)

Companies are turning to AI for innovative supply chain transformation. 86% of supply chain professionals agreed that AI is inevitable in their industry. AI serve as a guide to organizations, assisting them in making decisions based on factual data and insights. During product development process, machine learning algorithms can monitor and gather information about various products from the internet. there are thousands of FMCG products in the market. AI can detect patterns in design and help business to avoid duplication or designs that fail to perform. In addition, it could test the formulations before manufacturing to optimize quality ensure it complies to the regulatory. As a result, companies can minimize the risk of failure and loss of profit. For product placement, AI can categorize retails and customers and henceforth, suggest the best location and stores for specific products. For example, newborn products for a specified store had been sold for past 5 years, the AI will propose placing toys and necessities suitable for 5 year old child. Chatbots provides customer services 24/7 at reduced costs. Other than addressing customer’s enquires, they can serve as a salesman by recommending the personalized products to them.

Smart Shelves

More and more retailers are adopting smart shelves which have electronic labels, Radio-frequency identification (RFID) technology and IoT sensors. Smart shelves are able to communicate with customers. IoT connected devices such as beacons and smart shelves to provides deep insight of preference and capture path to purchase which helps to design store layouts. Another example of IoT is to provide targeted messages to customers while they are shopping. A RFID tag which contains a microchip antenna can transmit data to the reader. Information is received from the radio waves and then transfer to data to IoT platforms where it is stored and analyzed. Retailers utilize RFID technology to control and track inventory in supermarkets. Smart shelves that are installed with weight sensors and RFID notify the back-end system about the existing quantity of items on the shelves and the movements. Retailers can gain insight of customer behavior, automate replenishment, manage inventory, prevent theft, items not misplaced on various shelves and optimize store performance.

Smart Warehouse

A smart warehouse uses machines and computers to process warehouse operations and improve the flow of the warehouse. It has become increasingly important for large scare warehouse. Some of the benefits of smart warehouse are improving labour efficiency, faster turnaround times, increase warehouse transparency, reduce human error, improve scalability, and customer satisfaction. One of the technology used in smart warehouse is robots. It automates the product retrieval process by picking and delivering the items to the human. Warehouse can hold 50% more and retrieve stocks 3 times faster than human. For example, E-commerce running 24/7 requires warehouse staff to organize at an incredible speed to keep up with the purchase order. Manpower and time are reduced by deploying robots to pick the goods from the shelves and the staff will only have to focus on packing at respective station. Another technology commonly used is Automated guided vehicles (AGVs). It can assist with loading, unloading, transportation efficiently by moving self-governing throughout a warehouse. AGV can work round the clock with minimal downtime therefore, labour and time are reduced significantly.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Goh Siang Wei, DLSM. (2020). “Technologies for Warehouse Automation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-warehouse-automation/,accessed 16/09/2021.

IT Convergence. (2021). “Benefits of using Robotic Process Automation (RPA) in Retail Industry”. Retrieved from https://www.itconvergence.com/blog/robotic-process-automation-rpa-in-retail-industry/, accessed 16/09/2021.

Kelly Ho Lay Tin, SDDP. (2021). “Digital Technologies for Efficient Procurement”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technologies-efficient-procurement/,accessed 16/09/2021.

Lim Hun Meng, GDSCM. (2019). “Data Analytics for Optimizing Inventory”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/data-analytics-optimising-inventory/, accessed 16/09/2021.

Naveen Joshi. (2020). “How AI can speed up the FMCG sector: Ai in FMCG. Application development”. Retrieved from https://www.allerin.com/blog/how-ai-can-speed-up-the-fmcg-sector, accessed 16/09/2021.

Tea Min Lyn, GDSCM. (2019). “Five applications of blockcha in technology for a Digital Supply Chain”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/five-applications-blockchain-technology-digital-supply-chain/, accessed 16/09/2021.

Yau Wai Mei, DPSM. (2019). “Six important IOT Applications for Retail Procurement”. Retrieved from SIPMM:https://publication.sipmm.edu.sg/six-important-iot-applications-retail-procurement/,accessed 16/09/2021.