Warehouses are playing an important role in logistic as it can be an assembly line, fulfillment center as well as customer service or collection point. In the present, technology is important for every sector of the economy in the fast-paced. Besides, technologies for warehousing is one of the key drivers to ensure the goods flow effortless, improve efficiency and productivity. What are the essential technologies for warehousing productivity?

Table of Contents

Automatic Guided Vehicles (AGVs)

Automatic guided vehicles are a driverless robot that can transport pallets, shelves, and goods in a dedicated area. AGVs work cumulatively with humans to transfer goods in a facility. It uses in many warehouses like ‘Alibaba Warehouse’ and ‘DHL Express’ to reduce shipment damage by the forklift and also minimize the accident in the facility. The picture below shows the AGVs were transferring the boxes on the shelve in a dedicated area.

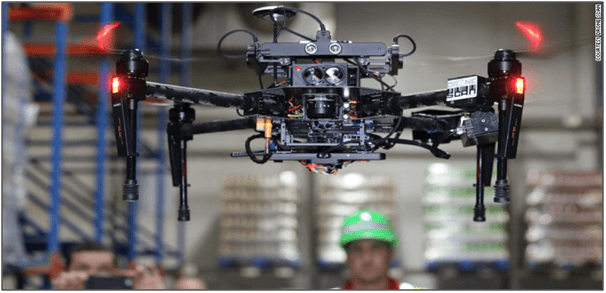

Drones Technology

Drones in the warehouse operations are really useful technologies to increase efficiency as it can reach to the height like perform capture and inventory check in the facility. It gives less hazardous tasks to humans as workers in the warehouse like do not need to climb up to a height to do a dangerous inspection. It can photo upload instantly to the system. Drones can be a central role in the facility and the main objective is to decrease the risk of falling from height and increase inventory accuracy.

Warehouse Management System

A Warehouse Management System is software that controls and support warehouse functionality. WMS allows for maintenance and visibility of the facility operation, include inventory receiving and put away, inventory management, picking, packing, replenishment, and reporting. It can easy to track shipments, perform cycle count in the warehouse and help users optimize inventory system. Furthermore, choosing the right WMS is essential based on the facility or organization’s needs or requirements to meet the unique needs. WMS brings few benefits for the warehouse-like such as reduce fulfillment time, increase warehouse productivity, inventory accuracy, improved customer service, greater space utilization, as well as reduce labor costs.

RFID Technology

Radio-frequency identification is a technology whereby digital data encrypted in RFID tags and smart labels are scanned by a reader via radio waves. RFID can transmit and exchange the data between RFID transporter and reader. RFID technology can be used to perform tasks like asset tracking, inventory management, and supply chain management. RFID tags are benefits than traditional bar-code labels as it can read faster and high durability. RFID tags can be scanned even have a line between them and also can be read much greater distance.

There are several benefits to use RFID in the warehouse:

- RFID tags can be captured in any position of sight with the scanner.

- The bar-code can be scanned at up to 300 ft.

- Can reusable and rugged as they are protected by a plastic cover.

- Humongous data capabilities, shipping histories, and expiry dates; which can all be programmed to the tag.

- More secure and data encrypted and password protected.

- Perform routine logistics operations such as stock storage, order status, paper processes, sorting, cycle counts.

Internet of Things (IoT)

Internet of Things is getting used for warehousing equipped with technologies that allow collecting data, perceiving and report. Internet of things has been used in warehousing such as inventory tracking, managing procurement, production, workflow and integration with supplies. To meet the customer’s demand, warehouses turn to IoT applications such as Alibaba, Amazon, and DHL Express all implement the technology to take inventory to the highest level.

The Internet of things offers a lot of benefits to organizations and enabling them to:

- Reduce costs and save more time

- Higher employee productivity

- Generate more revenue to the company

- Reduce various mistakes in the process due to human limitations

- Monitor the whole process and improve the performance of a business

Pick to Light and to Put to Light Technology

In a high-intensity warehouse where multiple picking and packing locations require the operator to be speed and accurate, a “pick to light and put to light” can be implemented to improve picking accuracy, as well as the speed of the pick performed by the warehouse staff. For example, goods are sent to the operator at an ergonomic height, and the indicator light informs the operator where they should be put and how many items to pick. The Pick-by-Light system is a light displays to direct warehouse staff for checking specific stock locations. Each product location will have an individual alphanumeric and numeric display with a light, a button and a digital display for indicating quantity. Put-to-Light system is a light displays that give the order to the warehouse staff as where and how to distribute or allocate stock to orders, allowing efficient picking in the warehouse. The operator scans each shipment and flashing light displays at the location indicate which containers require that product and how many items to place.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Jon Goh WoonKeong, DLSM. (2019). “Nine Technologies to Boost Warehouse Productivity”.Retrieved from SIPMM: https://publication.sipmm.edu.sg/nine-technologies-boost-warehouse-productivity/, accessed 07/09/2020.

Naresh Kumar, DLSM. (2019). “Digital Technology for Warehouse Productivity”.Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-warehouse-productivity/, accessed 10/09/2020.

Rick Chua Chee Hack, DPSM (2019). “Technologies for Effective Pharmaceutical Warehousing”.Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-effective-pharmaceutical-warehousing/, accessed 07/09/2020.

Wong Kam Foo, DLSM. (2020). “Technologies for Improving Logistics Productivity”.Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-improving-logistics-productivity/, accessed 07/09/2020.