Warehouse plays an important role for the organization to the company. It is not just a place for storing inventory. There are also several major operations functioning in the warehouse that are capable to pushing the organization’s growth to a greater degree and being a high potential company. Essential warehousing practices for logistics integration is a must for an organization to achieve the goal to become potentially and outstanding.

Table of Contents

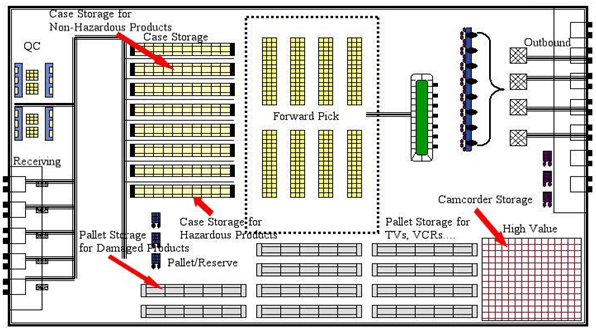

Importance of Warehouse Layout

One of the basics criteria of a well-run warehouse is a good layout that can lead to overall improved productivity. Some factors to be taken into consideration when deciding on the layout. There should be no cross-flow collisions in good warehouse layout and it should be regulated with good floorboard of continuous movement for workers, material handling equipment operating and for inventory storage. The accessibility of the products should be considered as well, for an instance how will the product be handled and transported. Available space utilization should be reserved for stock processing and operational storage.

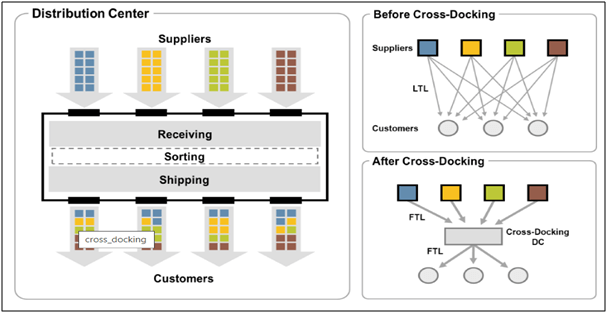

Cross Docking

Cross-Docking is a common warehousing strategy in many organization nowadays. Cross-docking is a distribution process where goods are shipped directly to a customer or retail chain from a manufacturer or a retailer facility, with less handling or with no storage time incur. Cross-docking take places in a distribution loading terminal usually on two (inbound and outbound) sides with limited storage space consisting of trucks and dock doors. This practice allows warehouse to keep a minimum stock level or sometime manage to keep “zero” incoming materials into the warehouse. Cross-docking is an efficient practice in handling incoming materials that are perishable or for inventory that have a very short shelf-life such as foods. This is a fast in and fast out transaction process.

Lean Receiving Operation

Receiving are the most active area fill with robust activity all the time. Any potential bottleneck cause in that area, might have a serious impact in the operation work flow. By applying an appointed turn for each deliveries to enter the loading dock, may reduce congestion. It might be time consuming, but it gives the advantage for the receiver to clear the receiving area before the next deliveries comes in. It can also reduce the possibility of error during receiving as there is no need for checker to rush to check all incoming deliveries at one go. With the help of modern technology, RFID (Radio Frequency Identification) Scanner is able to make receiving process become more effective and efficient. This helps warehouse teams do receiving fast and accurate and put-away straight all the incoming materials to the proper storage place. Such as example receiving for cold chain products. Receiving for cold chain materials must be fast to keep the freshness and quality of the products. That is why RFID manage to keep inventory’s data fast and storage goods in fast.

Order Picking Inventory

To achieve high customer satisfaction a streamline picking and packing method is required, this is important as customer demands for fast respond service nowadays. With the great contribution of technology, these techniques will make picking process quicker and more effective:

- Pick-by-Voice

- Pick-by-Light

- Pick-to-Light

- Put-to-Light

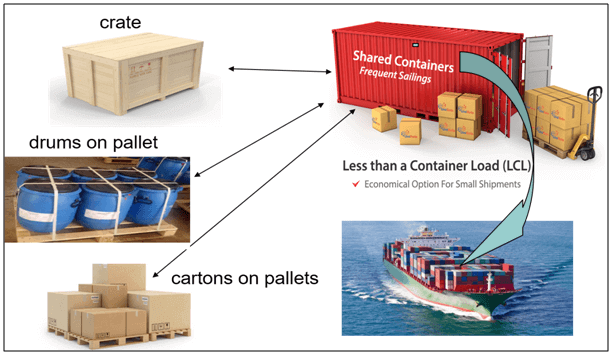

Packaging for Shipment

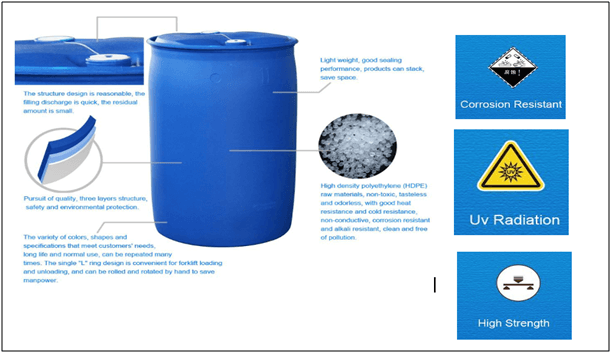

Packaging is one of the critical process for finished products before continuing to shipping. Depending on to which country or types of products that scheduled to be ship to and all the goods required to be pack accordingly to the standard packaging requirements before shipment. Good packaging can act as a safeguard to protect the finished goods, it also represents the quality of the goods inside the package. High valued or products with hazardous compositions are usually pack with extra care to ensure they are safe for shipping. There are various types of packaging like wooden case, carton box, PVC tubes and many. Some of them specially designed to decrease the damage impact to the product. The warehouse also needs automation technology such as Automatic Truck Loading (ATL) system to load goods to forwarder truck or direct into container for fastest shipping arrangement. Auto Shrink-wrapper machine manage to help to speed-up the timing for delivery compare with manual man-power shrink-wrapping. Pallet racking system helps to speed up the packaging process and with this fast and efficient process, the warehouse manages to keep less congested loading bays issue.

The picture below shows the packaging needed for loading on container and subsequent shipment.

The picture below shows the high durable drum packaging to keep goods safe.

ASRS in Warehousing

ASRS is a racking system that typically built-in warehouse to keep inventory systematically. This racking system replace large areas of shelving to save floor space in warehouse. This will help to improve worker’s safety and increase productivity in day-to-day activities in warehouse. Most importantly, ASRS can store inventory record securely in a compact footprint for easy traceability. When during stock count, ASRS can help company in how to tracking inventory information fast and easy. The picture below show ASRS stores huge and heavy materials in the racking system.

First-In-First-Out (FIFO) Inventory Control Method

FIFO is an inventory control technique practiced by many companies. The principle of FIFO is that the first goods received will be the first goods to be sold. Another simple example is, the first raw materials purchased in will be the first batch materials to production. First in first out is a very efficiency practice especially dealing with short self-life product or perishable products. With this, warehouse teams will be able to monitor inventory level smartly and this help to minimize possibility of obsolete items in the warehouse.

ABC Analysis for Inventory

ABC Analysis is a method that is often used for inventory control by categorize products/goods into three categories, according to the value of the items. The “A” items are the high expenses items and the most important products to the company. It is considered as the most valuable items that need to be pay high attention on it. The “B” items are less important compared to “A” items. The “C” items are considered “not important” items, compared to “A” or “B” items. The ABC analysis allows company to classify in which items that have a significant impact in their inventory cost and this help company can easily make decision for future planning.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Abel Seah Hock Siew, DLSM. (2020). “Essential Logistics Process for Cold Chain Operations”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-logistical-process-cold-chain-operations, accessed 10/09/2020.

Chong Yaw Wen, DPSM. (2019). “Essential Techniques for Inventory Control of Laboratory Equipment”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/essential-techniques-inventory-control-laboratory-equipment, accessed 10/09/2020.

Ng Li Hsia Alicia, DLSM. (2019). “Best Practices for Managing Warehouse Inventory”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/best-practices-managing-warehouse-inventory, accessed 10/09/2020.

Sarina Ammiruddin, DLSM. (2020). “Key Considerations for Effective Cargo Consolidation”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-considerations-for-effective-cargo-consolidation, accessed 10/09/2020.

Shankar Kumar, DLSM. (2019). “Technologies for More Productive Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/technologies-more-productive-warehousing, accessed 10/09/2020.

Syed Muhamad Faizal, DLSM (2017). “The Five Essential Methods for an Efficient Warehouse Operation” Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-essential-methods-efficient-warehouse-operation/, accessed 12/09/2020.

Wang Li Xing, DLSM.(2019). “Key Techniques to Improve Warehouse Productivity”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/key-techniques-improve-warehouse-productivity, accessed 10/09/2020.