Although globalisation significantly reduces the vastness between various regions worldwide, the physical division of these same regions is still a prominent reality. As the distances between regions widen, the higher the possibility that shipments are susceptible to damages in any complex transport operations.

Damages to goods can range from impacts to undesired temperature fluctuations inclusively, especially for perishables like food produce, their quality will deteriorate overtime due to the sustainability of their chemical reactions is highly dependent on low temperature consistency.

Timely coordination is necessary to efficiently transport a shipment and to prevent any delays that can have undesirable consequences. To safeguard cargoes from sustaining damages throughout a supply chain process, companies from pharmaceutical, medical and food & beverage industries are progressively relying on cold chain.

Table of Contents

Importance of Cold Chain Logistics

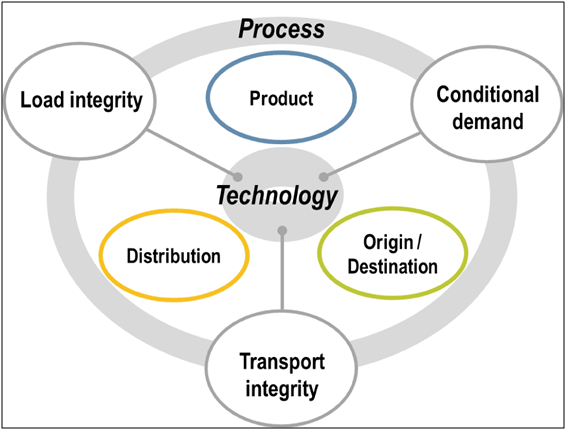

Cold chain logistics is principally a technological process, which safeguards the transportation and integrity of products and goods that are vulnerable to temperature changes along the supply chain. This process normally involves using thermal, refrigerated packaging methods and strategic logistical planning to effectively execute cold chain operations. Notable transportation mediums are refrigerated trucks, rail cars, cargo ships, reefers and air cargoes inclusively. It is also considered a science as it is greatly reliant on a profound knowledge of the chemical and biological processes associated with perishability.

Successful cold chain operations consist of these elements:

- Cooling systems – methods of conveying perishables such as foods to a suitable temperature during all aspects of the supply chain such as processing, storage and transportation.

- Cold storage – utilising facilities for the storage of commodities over a time frame, pending for shipping to a certain market or intermediate location for processing and distribution.

- Cold transport – ensuring transportations are available for goods while sustaining constant temperature, optimal humidity levels and preserving integrity.

- Cold processing and distribution – having the resources to alter and process commodities with good sanitary conditions. Ability to consolidate loads with crates, boxes and pallets for distribution.

Providing Temperature Controlled Environments

Cold chain operations have recently improved significantly and is able to encompass the requirements of an extensive range of products. Different products have specific maintenance temperature requirements to safeguard their integrity throughout the supply chain. The cold chain industry has provided with the settings of temperature standards to accommodate the bulk of products. Standard temperature settings are “Banana” at 13°C, “Chill” at 2°C, “Frozen” at -18°C and “Deep-Frozen” at -29°C. Maintaining within these temperature settings is essential to the integrity of shipments and to ensure ideal shelf life of perishables.

Cold Chain Shipment Preparation

It is critical to first assess the characteristics of any temperature-sensitive produce prior to transportation. The temperature conditioning and packaging of the cargo must be maintained at the desired temperature. Cold chain devices are principally designed to maintain constant temperature and not to generate a shipment to this temperature. This will prevent the shipment from performing inadequately if it is not conditioned properly in advance. Other concerns are the destinations and weather conditions of the regions for the shipments. For example, if a shipment is vulnerable to extreme heat or cold temperature along the shipping route, using a self-powered reefer will alleviate such concerns.

The loading unit transporting the cargo also requires adequate preparation. An instance would be a refrigerated container is ought to be steam-cleaned to remove the risk of bacterial contamination and maintaining the temperature and humidity conditions specified by the shipper. Next issue is atmospheric control that is sustaining appropriate oxygen and carbon dioxide levels, which aids in delaying the ripening of fruits like bananas. Packaging materials like polyethylene bags, will aid in controlling how gases permeate during the whole transportation.

The Last Mile

The final stage would be the actual delivery of the shipment to its destination. In logistical term commonly known as the “Last Mile”. Not only the destination is a crucial consideration when arranging a final delivery, the timing of the delivery to ensure the labour and warehousing space is readily available is nonetheless important. Primary transport mediums like lorries and vans, must have the specific requirements necessary to transport the cold chain shipment. Not to mention that many deliveries of cold chain products (e.g. groceries) are happening in urban environments, which can be hindered by traffic congestions. Most important factor would be the final transfer of the cargo to the cold storage facilities, as there are possibilities for damages and violations of integrity to delicate goods such as fruits and vegetables.

AS/RS to Improve Cold Chain Performance

Automated Storage and Retrieval System (AS/RS) is an extensively used inventory management system in warehouses, manufacturing facilities and distribution centres throughout various regions worldwide. AS/RS involves machineries that move vertically upwards and downwards, across multiple corresponding storage aisles. Its core functions would be storage and retrieval of products for distribution to in-house and external destinations likewise.

An abundance of advantages can be obtained from AS/RS implementation. Users benefit from enhanced inventory control, tracking and better flexibility to encounter any undesirable business fluctuations. These systems consist of modular sub-systems that can be interchanged with ease to minimise on downtime and increase overall systems’ service life. It also greatly reduces labour costs and enhancing workplace safety by eliminating employees from working in harsh working environments such as cold stores or freezer facilities. Employees’ turnover rate are indirectly reduced from aforementioned measure.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Asia Pacific Food Industry. (2018). “10 Ways ASRS Reduces Costs and Improves Cold Chain Performance”. Retrieved from https://apfoodonline.com/industry/10-ways-asrs-reduces-costs-improves-cold-chain-performance/, accessed 11/03/2020.

Joey Yeoh, PDLM. (2017). “The Logistics of Transporting Perishable Goods for Cold Chain Management”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/logistics-transporting-perishable-goods-cold-chain-management/, accessed 14/03/2020.

Jean-Paul Rodrigue. (2020). “The Cold Chain and its Logistics”. Retrieved from https://transportgeography.org/?page_id=6585, accessed 11/03/2020.

Michelle Lee Ean Wei, DLSM. (2018). “Digital Technology for Cold Chain Distribution”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/digital-technology-cold-chain-distribution/, accessed 14/03/2020.

Nuraini Ooi, DPSM. (2019). “New Technologies for Cold Chain Logistics”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/new-technologies-for-cold-chain-logistics/, accessed 12/03/2020.