Inventory control in the food industry is quite different from that in other industries. Food products are often perishable and have a limited shelf life, thus there is a need to comply with food safety and health standards. The most appropriate techniques must be in place to manage the supply chain including tracking each batch during manufacturing, packaging and delivery while ensuring safety of goods for consumers at every stage. Without the right techniques to control inventory, there is a high risk of running out of stock, having excess and obsolete stock, or facing spoilage.

Table of Contents

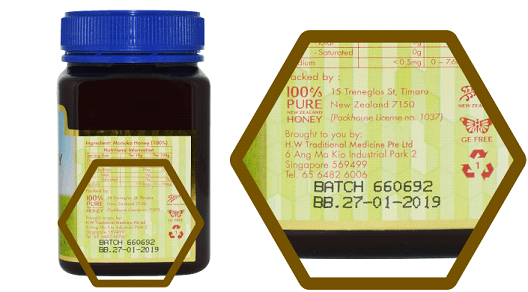

Batch Number Tracking

There is always a constant risk of contamination at any stage of the supply chain for Food and Beverage (F&B) businesses Perishable products, especially fresh produce, are particularly susceptible to spoilage due to improper storage. In the event of contamination or spoilage, the company must be ready to run a recall for the affected products. The batch number tracking technique is one method which can help food businesses when they want to recall contaminated food products. The major causes of food poisoning are bacteria like Salmonella, Botulism or E. Coli which have led to product recalls in countries all over the world. For example, in 2015, 19 people across the U.S. suffered from food poisoning caused by E. Coli after eating at Costco’s rotisserie chicken salad and the farm responsible issued a recall of all affected products. Health officials released warnings to Costco’s customers to check any uneaten salads with a label numbered 37719 and consumers were advised to throw it away. Costco’s ability to pin down the contaminated salads to batch number 3771 was because the batch number was clearly printed on the container.

The most important step in dealing with a food recall is a prompt and effective response. Batch tracking capabilities must always take a proactive approach to product recalls, particularly in a food manufacturing or wholesaler business. When the company can find where the affected food products are and take measures to speed up the process, it can nip the problem in the bud before it reaches the end customer. This minimizes damage to the reputation of a brand, which is essential to a positive long-term relationship with food retailers.

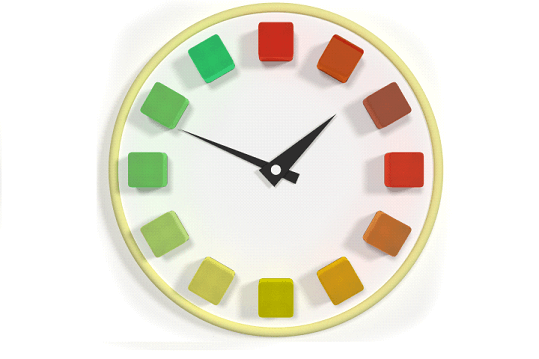

Using Color-changing Tag Techniques

Color-changing tags, also known as “time-temperature labels”, are another method of tracking food inventory especially for chilled and freezer items. These tags can change color with the change in time and temperature. They are made from silver and gold materials which allow it to change color based on how fresh the food products are. They are accurate, easy to read, number-free and inexpensive. This particular technique can help food businesses track the degree of freshness of food and allow control over food safety. As shown in the image of the color-changing tag below, the tags will morph as time passes, from a rich red color to a bright orange, to a murky yellow and finally to a grungy green. The green color indicates that the food is spoiled. If the food product has been kept within the recommended storage temperature range, the tags will change color with accordance to its expected shelf-life. However, if the product is kept in an environment not within the desired temperature range possibly due to sub-standard refrigeration units, the color tags will change color more quickly, just like how milk will expire faster if kept in a non-chilled environment

Demand Forecasting of Seasonal Food Products

There are periods of the year where certain food products may be greater in demand and this fluctuation is referred to as seasonality. This phenomenon poses a great challenge for the food inventory control and must be managed carefully to consider changes in trends that may affect its popularity.

Seasonal products present businesses with a great opportunity for increased profitability. Food businesses must navigate through these shifts by utilizing accurate forecasts to fine-tune their seasonal demand planning and holding just enough inventory to meet the influx in demand without losing sales to stock outs.

When it comes to managing seasonal inventory, the food business can categorize inventory stock by separating purely seasonal stock such as Christmas turkeys, sausages and Christmas roll cakes in the Christmas season from the perennial products to ensure the food business is not left with an excess of purely seasonal items. The company can closely analyze historical data, seasonal patterns, and variations to help identify any annually recurring trends in sales and set minimum stock levels of various seasonal stock. It can determine seasonal demand timelines to identify the lengths of these peak seasons and find food product lead times from the ordering process to the final delivery. It must continue to review the accuracy of their seasonal demand forecasts and make the appropriate adjustments if some food product fails to move as quickly as anticipated. The company should also consider offering discounts towards the end of the peak seasons for seasonal food products to prevent excess inventory or dead stock.

The full content is only visible to SIPMM members

Already a member? Please Login to continue reading.

References

Chia Pei Ying, DPSM. (2018). “Five Techniques for Managing Inventory in the Precision Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-techniques-managing-inventory-precision-industry , accessed on 16/06/2021.

Elisabeth Skoda. (2017). “A Smart Way to Reduce Food Waste”. Retrieved from: https://packagingeurope.com/a-smart-way-to-reduce-food-waste/, accessed on 17/06/2021.

Jin Hyun. (2020). “5 Top Tips for Forecasting & Managing Seasonal Products”. Retrieved from: https://zipforecasting.com/en/demand-planning/seasonal-products.html, accessed on 18/06/2021.

Kevin A. Nye. (2019). “Inventory Management Techniques for Effective Inventory Planning”. Retrieved from: https://www.kevinanye.com/inventory-management-techniques-for-effective-inventory-planning/, accessed on 18/06/2021.

Ong Yee Chiat, DLSM. (2017). “Five Important Techniques for Effective Inventory Control”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-important-techniques-for-effective-inventory-control , accessed on 16/06/2021.

Suzanna Sandridge. (2017). “First In, First Out (FIFO)”. Retrieved from https://www.statefoodsafety.com/Resources/Resources/april-cartoon-first-in-first-out-fifo, accessed on 11/06/2021.

Vera Lim. (2017). “Batch and Expiry Date Tracking for F&B Businesses”. Retrieved from: https://www.tradegecko.com/blog/inventory-management/introducing-batch-and-expiry-date-tracking, accessed on 17/06/2021.

Winnie Soh Pin Pin, DPSM. (2019). “5 Essential Technologies for Inventory Control in a Warehouse Contract”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-essential-technologies-inventory-control-warehouse-contract , accessed on 16/06/2021.