Many of the challenges that businesses face, such as running out of stock, or having excess stock (which translates to tied-up funds), or having obsolete stock or spoilage are as a result of poor inventory management. When you use inventory management software in conjunction with inventory control technology, you improve your bottom line. Using technology to augment inventory management helps your business to stay on top of things by streamlining the ordering and tracking process throughout the sales cycle of a product.

Table of Contents

Warehouse Management System (WMS)

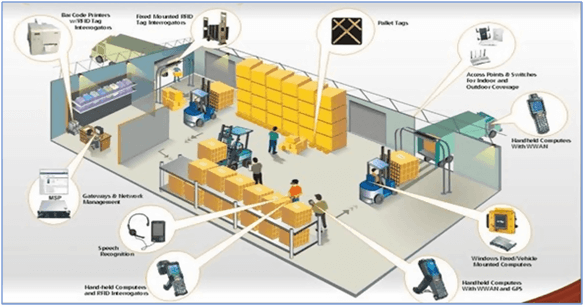

Warehouse management systems come in a variety of types and implementation methods, and the type typically depends on the size and nature of the organization. They can be stand-alone systems or modules in a larger enterprise resource planning (ERP) system or supply chain execution suite.

They can also vary widely in complexity. Some small organizations may use a simple series of hard copy documents or spreadsheet files, but most larger organizations — from small to medium-sized businesses (SMBs) to enterprise companies — use complex WMS software. Some WMS setups are designed specifically for the size of the organization, and many vendors have versions of WMS products that can scale to different organizational sizes. Some organizations build their own WMS from scratch, but it’s more common to implement a WMS from an established vendor.

A WMS can also be designed or configured for the organization’s specific requirements; for example, an e-commerce vendor might use a WMS that has different functions than a brick-and-mortar retailer. Additionally, a WMS may also be designed or configured specifically for the types of goods the organization sells.

Radio Frequency Identification (RFID) Technology

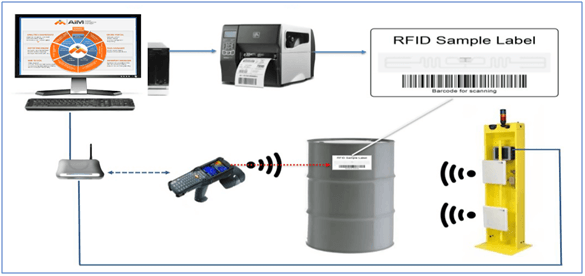

RFID is an acronym for “radio-frequency identification” and refers to a technology whereby digital data encoded in RFID tags or smart labels (defined below) are captured by a reader via radio waves. RFID is similar to barcoding in that data from a tag or label are captured by a device that stores the data in a database. RFID, however, has several advantages over systems that use barcode asset tracking software. The most notable is that RFID tag data can be read outside the line-of-sight, whereas barcodes must be aligned with an optical scanner.

RFID belongs to a group of technologies referred to as Automatic Identification and Data Capture (AIDC). AIDC methods automatically identify objects, collect data about them, and enter those data directly into computer systems with little or no human intervention. RFID methods utilize radio waves to accomplish this.

At a simple level, RFID systems consist of three components: an RFID tag or smart label, an RFID reader, and an antenna. RFID tags contain an integrated circuit and an antenna, which are used to transmit data to the RFID reader (also called an interrogator). The reader then converts the radio waves to a more usable form of data. Information collected from the tags is then transferred through a communications interface to a host computer system, where the data can be stored in a database and analyzed at a later time.

Light Fidelity (LiFi) Technology

LiFi is a technology for wireless communication between devices using light to transmit data and position. LED lamps can be used for the transmission of visible light. Providing wireless connectivity for a large number of robots and electronic devices is a challenging problem in warehouses and factories.

LiFi offers huge advantages over WiFi in those environments and can be used as a reliable wireless networking technique in those indoor areas. In addition, visible light communication can provide accurate 3D positioning for robots, drones and other devices in warehouses and factories, where indoor positioning and navigation is a crucial element.

The picture below shows the MiFi technology connected to the drone and robots to perform the warehouse activities.

Barcode System

You see barcodes everywhere – from identification cards, to mail, to goods you purchase in a store. The small image of lines, or bars, and spaces are affixed to nearly everything you can imagine, for identification purposes. Specifically, barcodes use a sequence of vertical bars and spaces that represent numbers and other symbols; typically, a barcode consists of five parts – a quiet zone, a start character, data characters (often including an optional check character), a stop character, and another quiet zone.

Barcoding increases efficiency and productivity in a number of industries when paired with barcode readers. Barcode readers use laser beams to read the barcodes and translate the reflected light into data that is then transferred to a computer for action or storage. Most people are familiar with barcodes and barcode readers in supermarkets and retail stores. However, barcodes are useful in several other applications, from taking inventory to checking out books, to tracking bees for research. Barcode readers often are attached to computers in retail settings, but they also are handheld and portable for other uses, such as scanning barcodes in warehouses and tracking inventory.

Robotics Technology

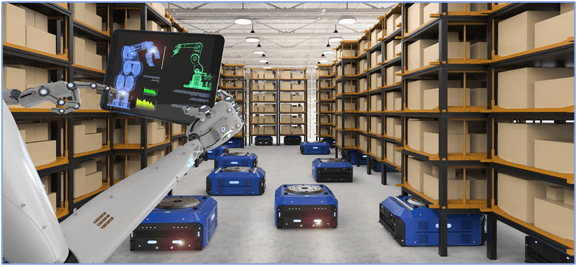

New robotics technology has become one of the most sought-after technologies for warehouse management. Leading-edge manufacturers are partnering with providers of warehouse management systems to create customized software and smart robots that help to manage the movement, storage, and sorting of warehouse inventory.

With increasing order volumes, numerous products to navigate, highly personalized order packing and faster shipping requirements, robotics solutions will help effectively respond to volume growth and perform more tasks with lesser labor and at a lower cost. The increasing demand for higher levels of performance and flexibility in warehouse robotics is stimulating some innovative product developments and early adoptions of mobile warehouse robotics. As a warehouse manager, one should choose a robotic technology that best caters for their needs in all aspects of workflow.

Conclusion

The technology you chose will all depend upon the business you’re conducting and the essentials you feel must be fulfilled. The bottom line is that inventory control is vital to the survival of your business. If you don’t have a good handle on your inventory you’ll never have a true account for how your business is doing. It is a competitive market out there. Do not let inventory excess or shortages become your downfall.

References

AB&R. (2018). “What is RFID and How does RFID work?” Retrieved from https://www.abr.com/what-is-rfid-how-does-rfid-work, accessed on 12/03/2019.

Chia Pei Ying, DPSM. (2019). “Five Techniques for Managing Inventory in the Precision Industry”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/five-techniques-managing-inventory-precision-industry, accessed on 12/03/2019.

GT Staff. (2016). “Automatic Truck Loading and Unloading Technology Coming to U.S.Market”. Retrieved from http://www.globaltrademag.com/global-logistics/automatic-truck-loading-unloading-technology-coming-u-s-market, accessed 12/03/2019.

Margaret Rouse. (2017). “Warehouse Management System (WMS).” Retrieved from https://searcherp.techtarget.com/definition/warehouse-management-system-WMS, accessed on 12/03/2019.

Nicole Pontius. (2015). “ What is Barcoding and Barcoding Applications.” Retrieved from https://www2.camcode.com/asset-tags/what-is-barcoding, accessed on 12/03/2019.

Olivia Durden. (2019). “How to Use Technology to Track Inventory.” Retrieved from https://smallbusiness.chron.com/use-technology-track-inventory-64737.html, accessed on 12/03/2019.

Surendran. (2018). “Adopting New Technologies for Effective Warehousing”. Retrieved from SIPMM: https://publication.sipmm.edu.sg/adopting-new-technologies-effective-warehousing, accessed on 12/03/2019.